Transportation component, suspension transmission system and electroplating line

A technology of components and transmission shafts, applied in the field of transmission, can solve the problems of unstable operation and low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

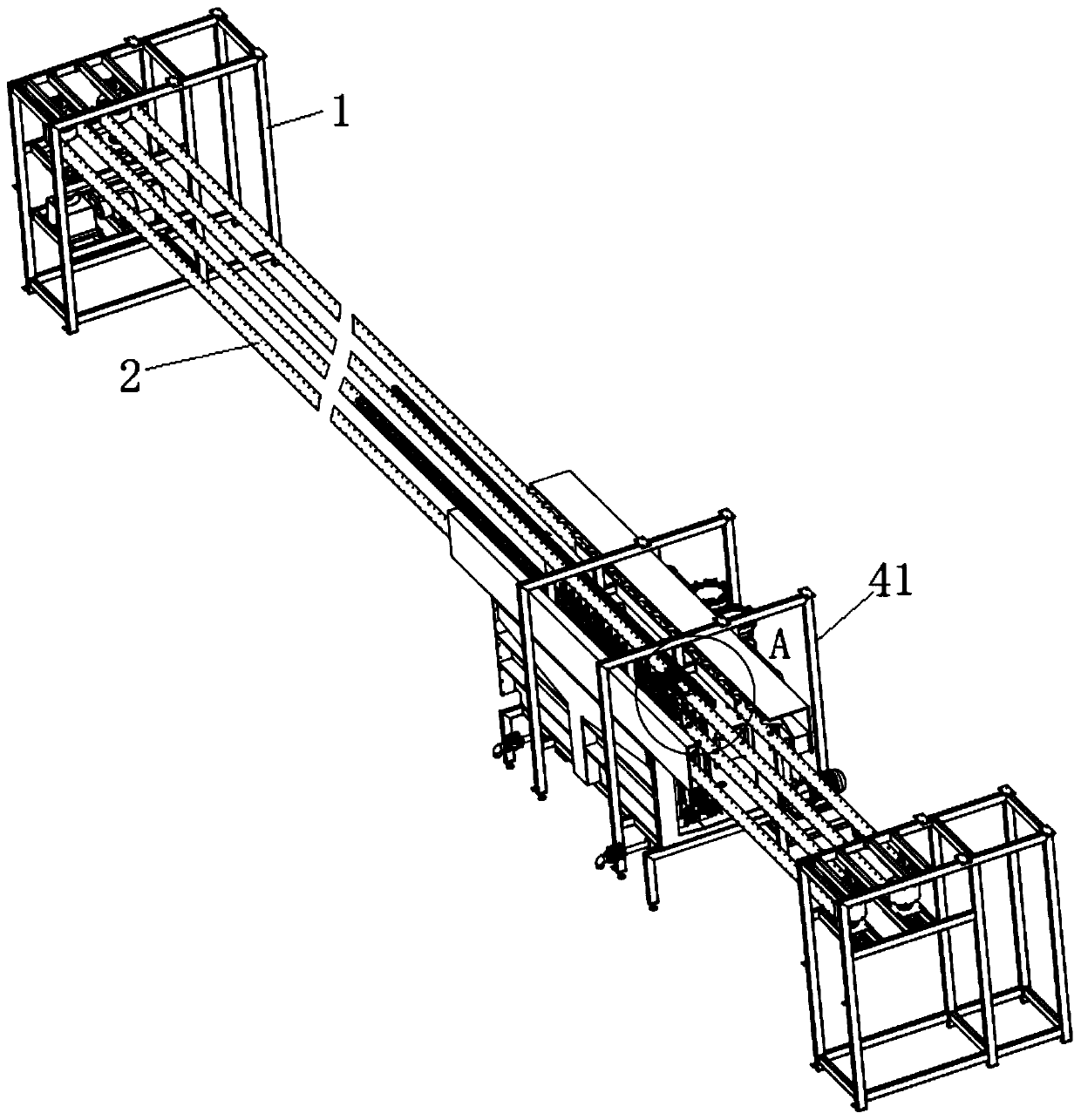

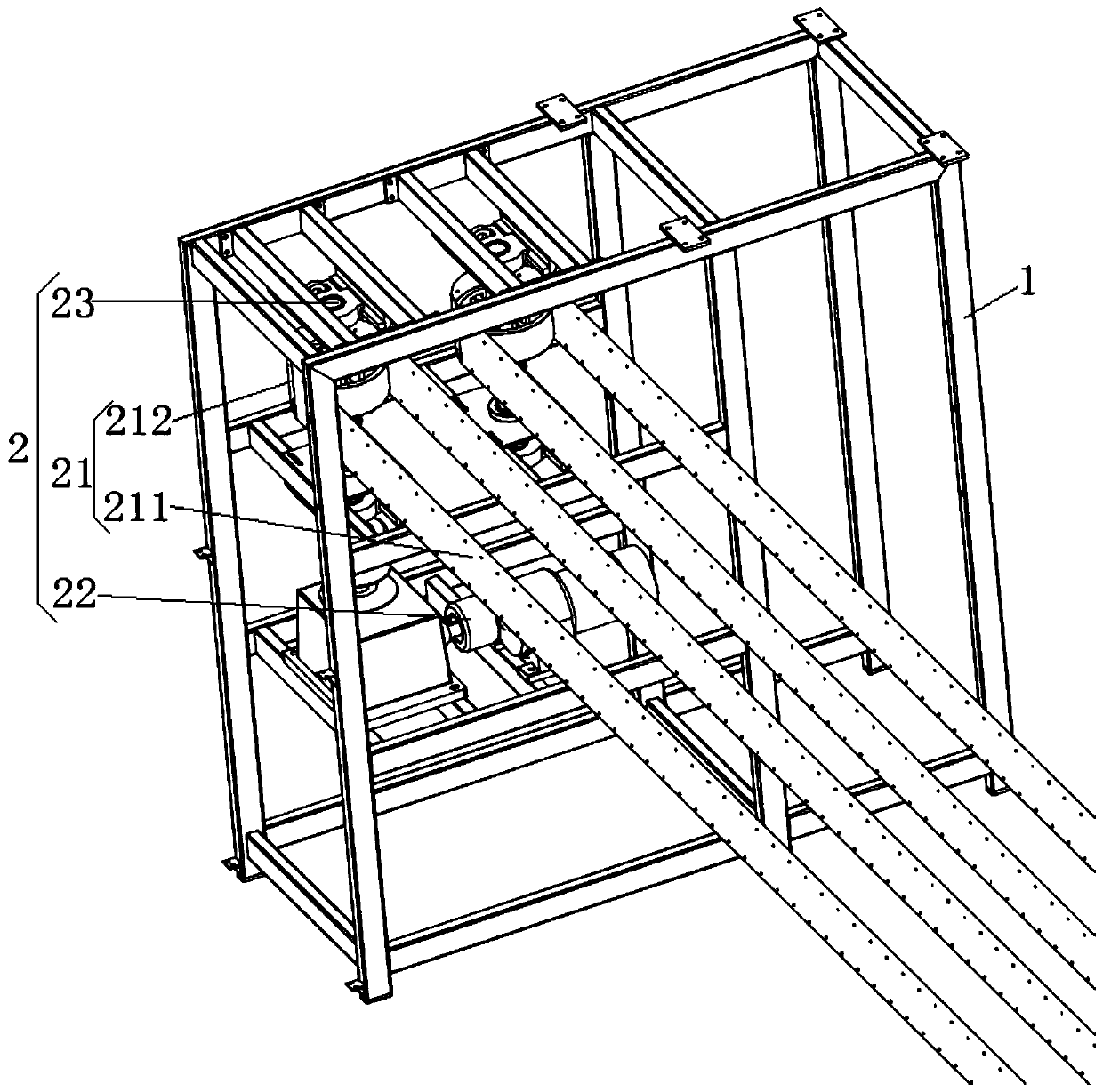

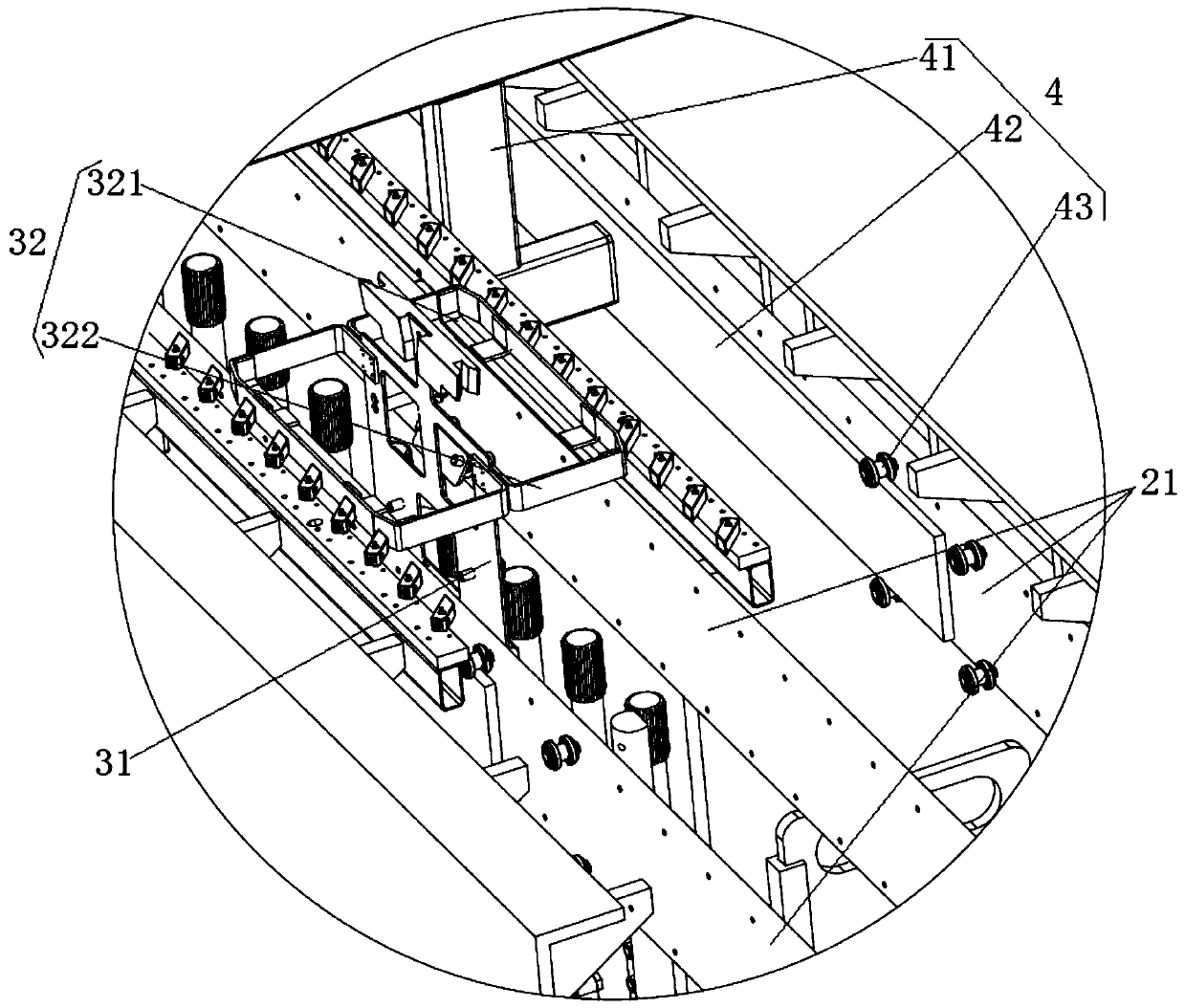

[0063] This embodiment provides a transport assembly, such as figure 1 and image 3 As shown, it includes a frame 1, two circulating transmission devices 2 and at least one hanger 3, the hanger 3 is located between the two circulating transmission devices 2, each hanger 3 includes a hanger and two sets of matching parts 32, two The group matching parts 32 are respectively arranged on both sides of the pendant, and the matching parts 32 are correspondingly and linkedly arranged on the circulating transmission device 2. The two circulating transmission devices 2 form a double-sided bridge structure, and the hanging device 3 is connected to the double-sided bridge structure. On the other hand, two circulating transmission devices 2 drive the hanger 3 to run, so that the force on both sides of the hanger 3 is balanced, and the operation is more stable. At the same time, the concentration of force on one side of the single circulating transmission device 2 is avoided, and its servi...

Embodiment 2

[0072] This embodiment provides a suspension transmission system, including at least one clamp 30 and the transport assembly in Embodiment 1. Such as Figure 4 As shown, the clamp 30 is fixed below the hanging board 31 and is suitable for moving with the hanging device 3 .

Embodiment 3

[0074] This embodiment provides an electroplating line, including the suspension transmission system in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com