Rail and rack integrated type attached wall supporting device as well as attached wall support seat and jacking method of supporting device

A technology of wall-attached support and support device, which is applied in the direction of building structure support, building structure support, scaffolding accessories, etc., can solve the problems of large size of fulcrum components, high labor intensity of installation and dismantling, and difficulty in multi-project generalization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

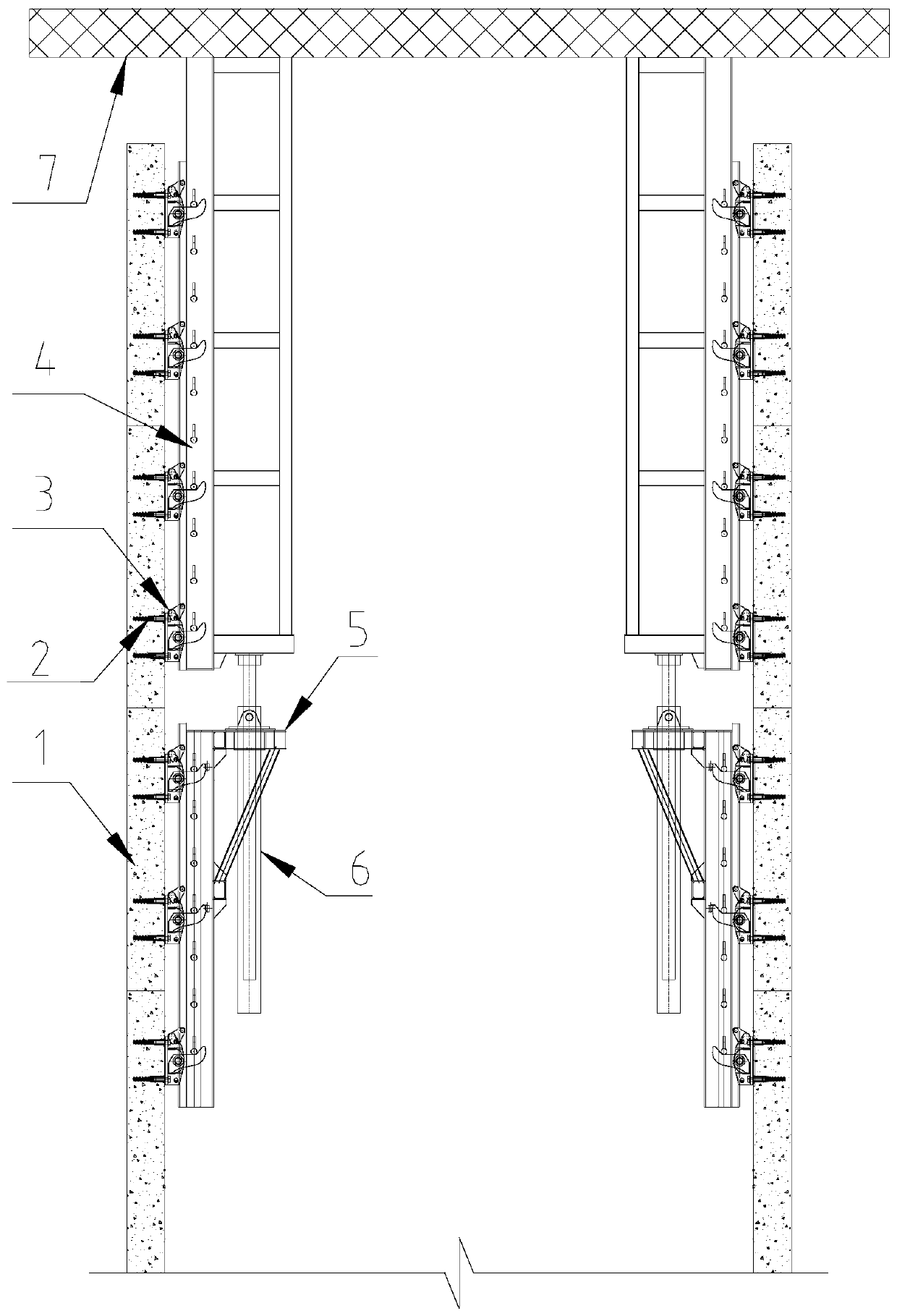

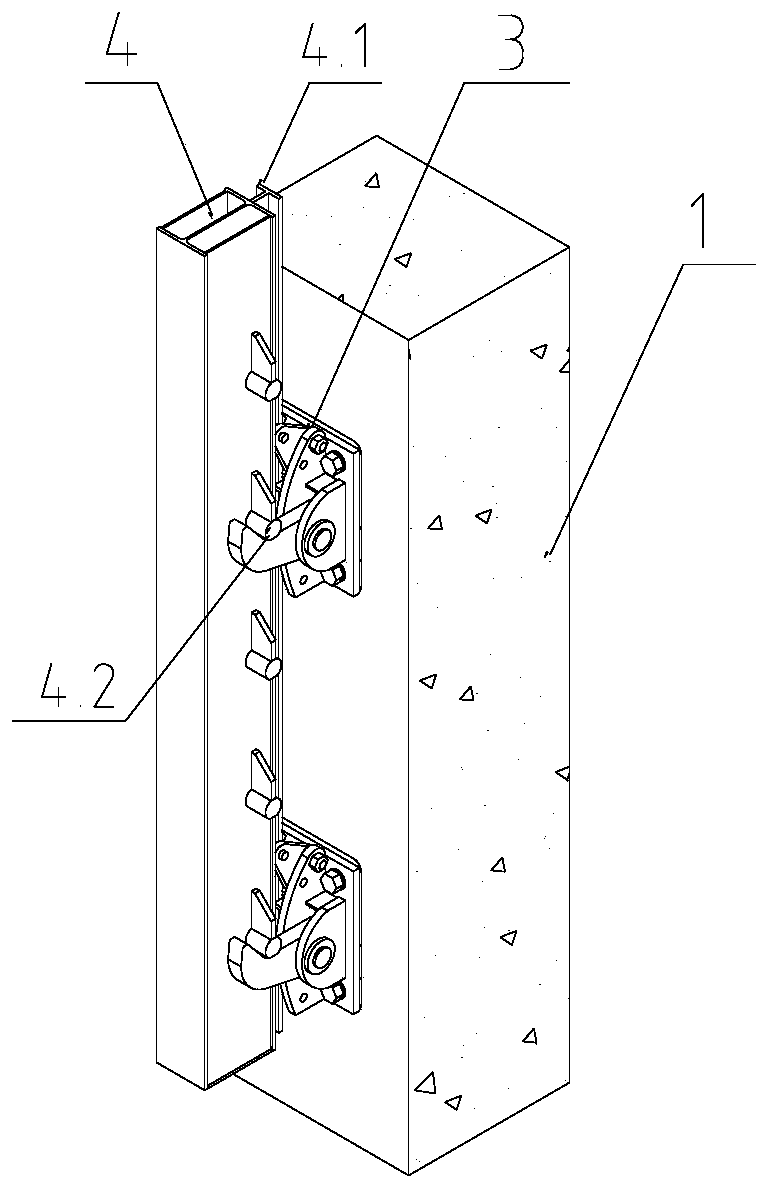

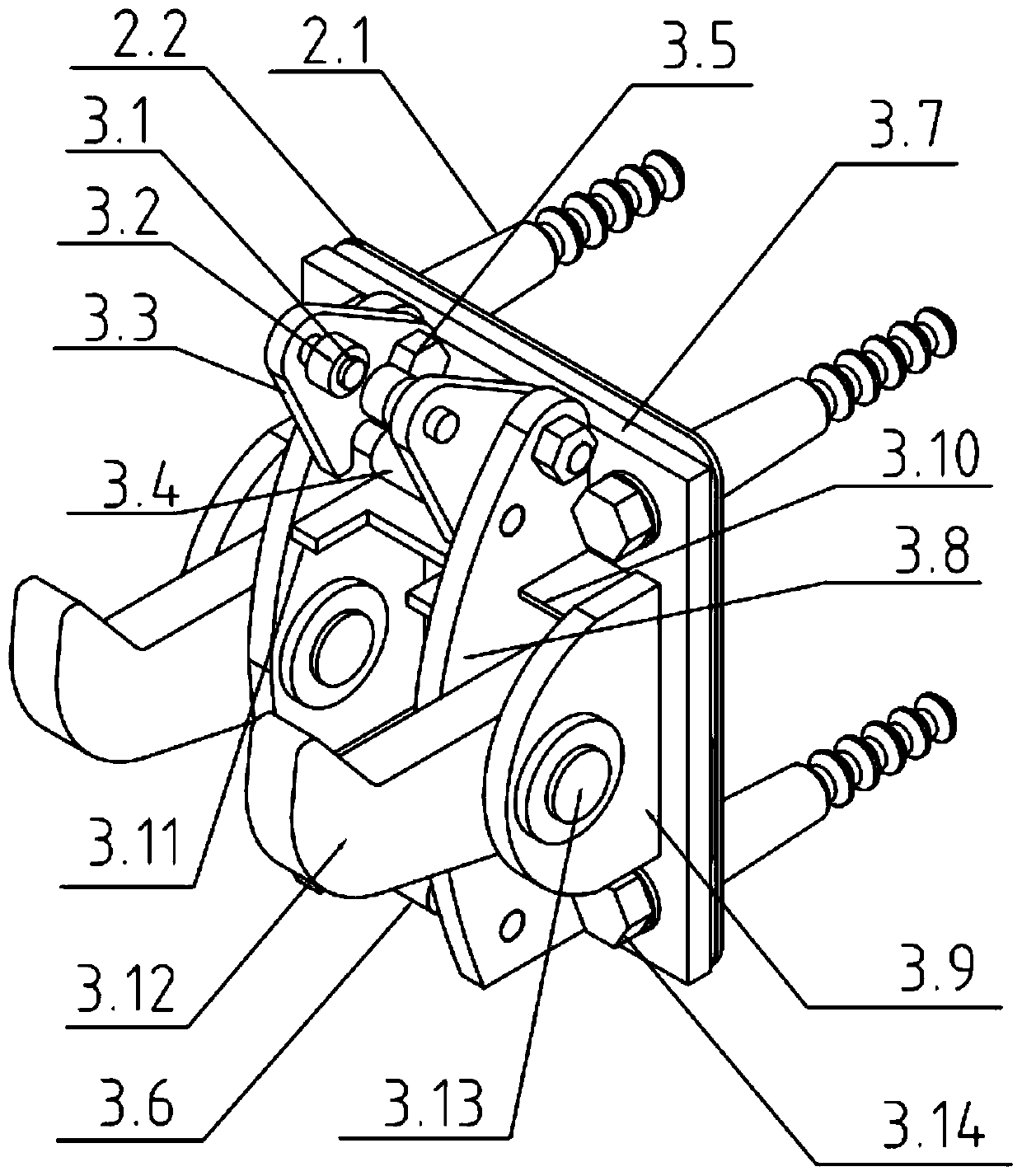

[0040] refer to Figure 1 to Figure 5b , in this embodiment, a rail-frame-integrated wall-attached support device includes a wall-attached support, and also includes a wall-attached connector 2 and a guide rail column 4, wherein,

[0041] The wall-attached support 3 includes a base plate 3.7, a supporting claw 3.12, a supporting ear plate and an anti-side guide mechanism, the supporting ear plate is fixed on one side of the base plate 3.7, and the supporting claw 3.12 is supported on the supporting ear plate and is rotationally connected with it (an attached The wall support 3 is provided with at least one supporting claw 3.12 and a pair of supporting lugs. In this embodiment, two supporting claws 3.12 and two pairs of supporting lugs are set as an example), the supporting claws 3.12 can be turned freely, and the supporting hooks Claw 3.12 is used to support the load-bearing rod 4.2 of guide rail column 4, anti-side guide mechanism includes inner side anti-side guide wheel and...

Embodiment 2

[0064] refer to Figure 6a and Figure 6b , The matching method between the wall-attached support 3 and the rail column 4 in this embodiment is slightly different from that in Embodiment 1.

[0065] In this embodiment, the supporting claw 3.12 and the anti-side guiding mechanism are consistent with the operating principle of embodiment 1, the difference is that a group of hanging shoes 3.15 (that is, the supporting device, A groove is formed by welding multiple plates), the cylinder bracket 5 can be hung on the hanging shoe 3.15 through the hook, and supported on the same group of wall-attached supports 3 at the same time as the guide rail column 4, using this shared wall-attached support 3, the position of the oil cylinder support 5 can be moved up by one structural layer, and the number of installations of the wall-attached supports 3 can be reduced.

Embodiment 3

[0067] refer to Figure 7a and Figure 7b , The matching method between the wall-attached support 3 and the rail column 4 in this embodiment is slightly different from that in Embodiment 1.

[0068] In this embodiment, the supporting claw 3.12 and the guiding anti-side mechanism are consistent with the operating principles of Embodiments 1 and 2, the difference lies in the following points:

[0069] 1. The number of supporting claws 3.12 of each wall-attached support 3 is one. At this time, in order to meet the assembly requirements after the structure of the supporting claws is changed, the load-bearing rod structure of the guide rail column 4 is also changed, and the corresponding position is adjusted to Between the two webs of the guide rail column;

[0070] 2. A set of hook lugs 3.16 (i.e. support device, structure slightly different from hanging boots 3.15 in Example 2, hook lugs 3.16 are added to the outer left and right sides of the supporting hook claw 3.12 of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com