Heat supply system of air source heat pump for phase change heat storage and logic control method thereof

An air source heat pump and heating system technology, applied in the field of heat pumps, can solve the problems of high equipment investment cost, low hot water temperature, and large power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technology will be further described below.

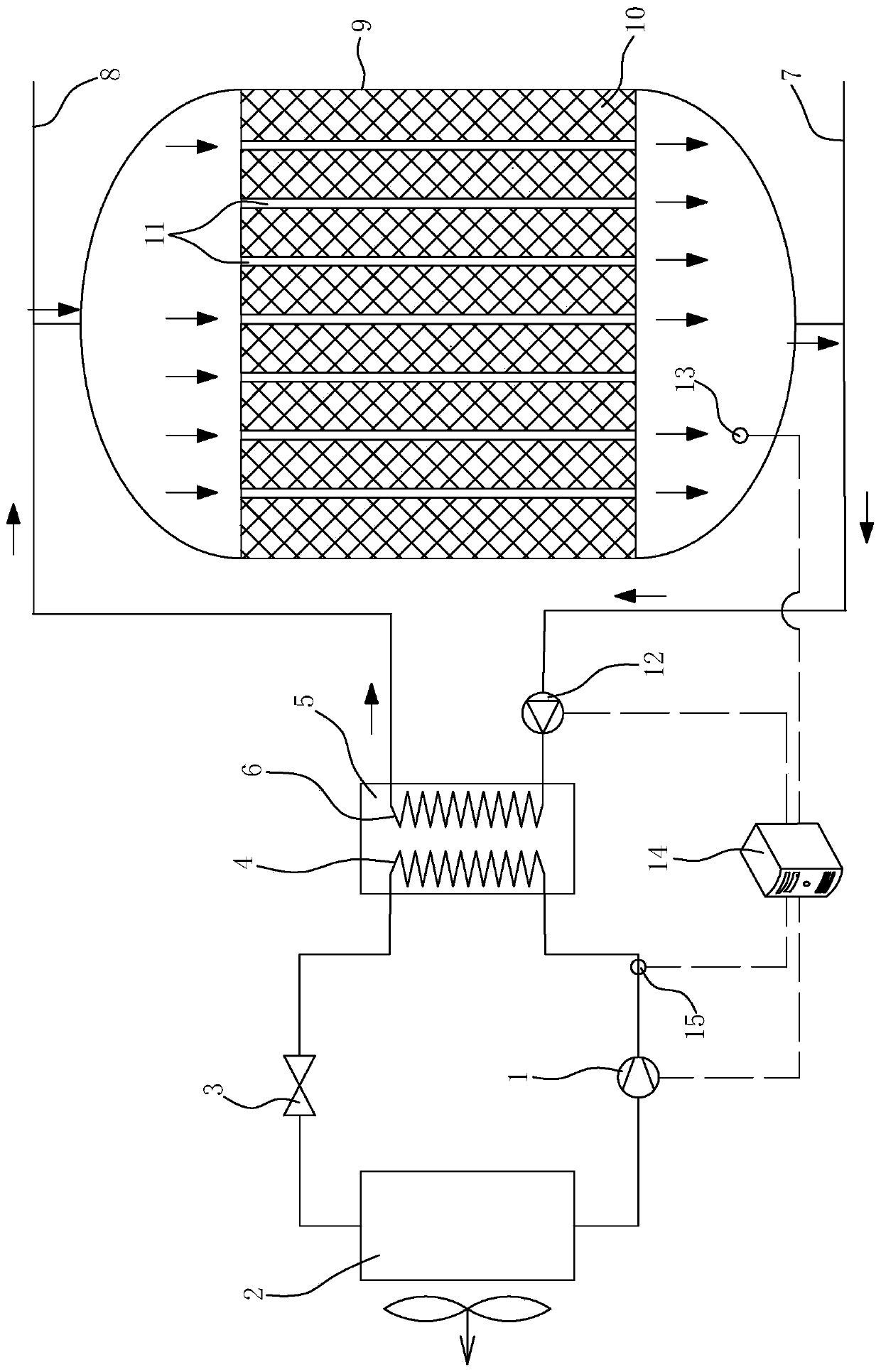

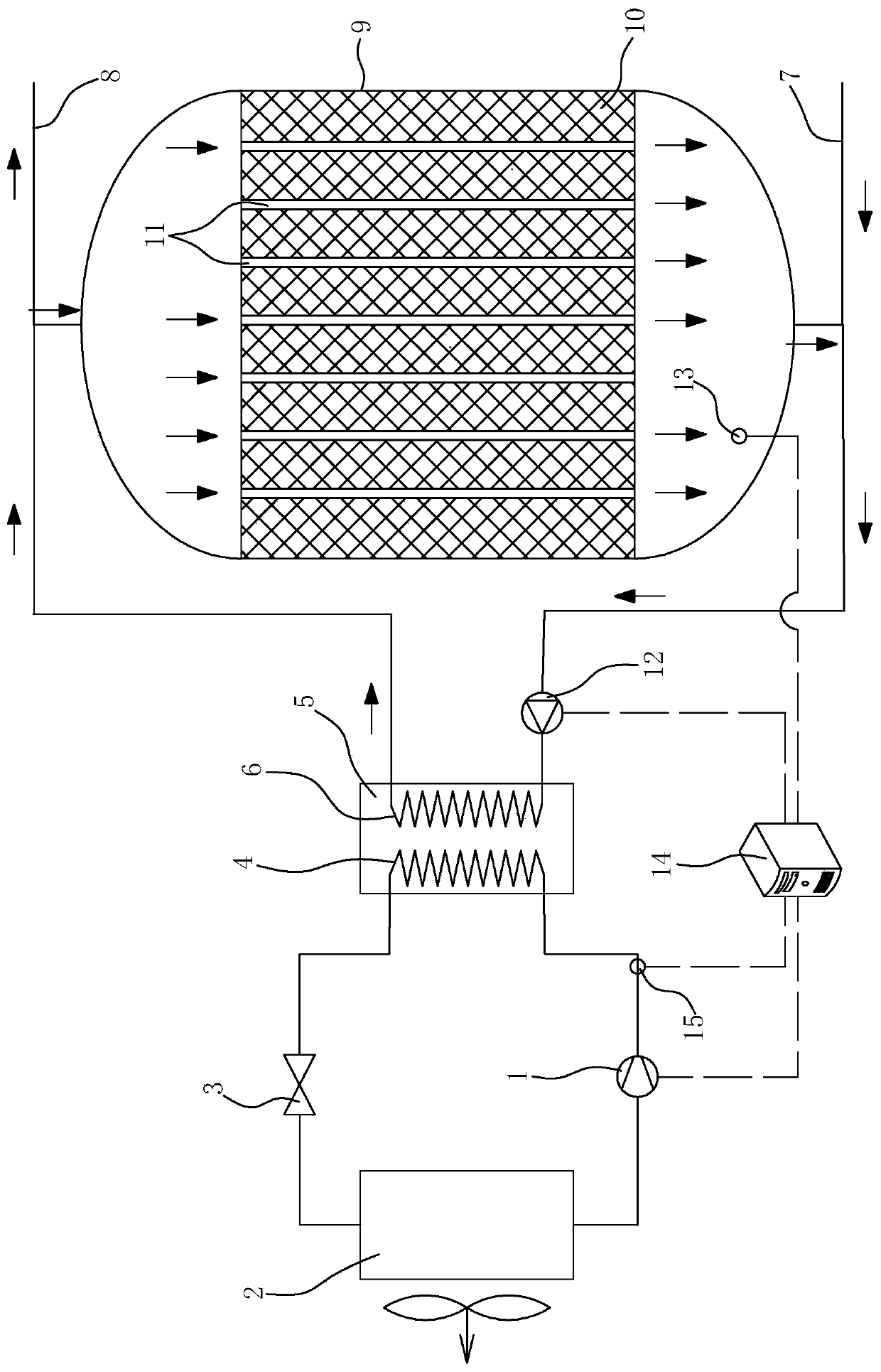

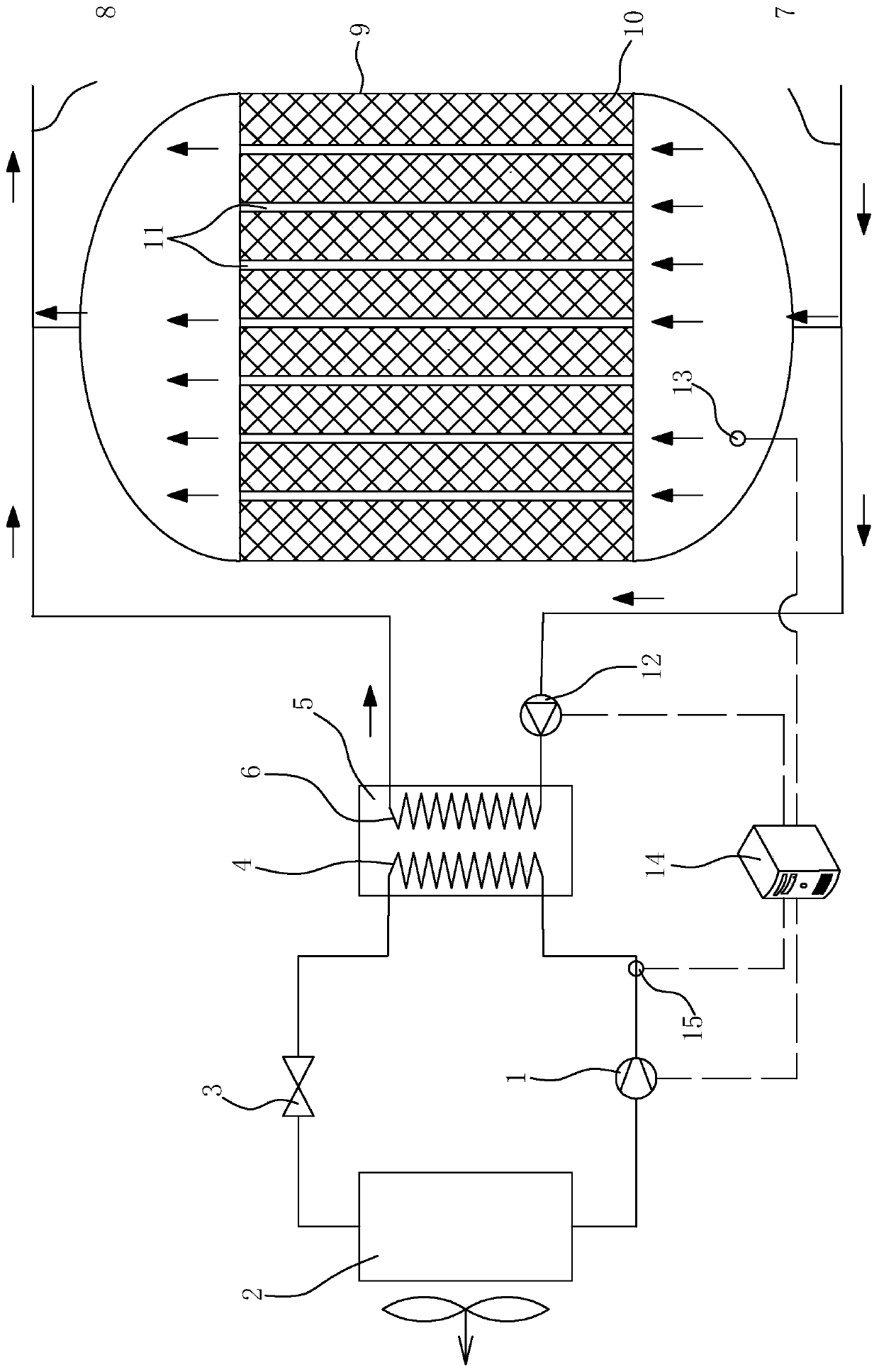

[0021] The air source heat pump heating system with phase change heat storage includes inverter compressor 1, evaporator 2, expansion valve 3, refrigerant side 4, condenser 5 and water side 6, starting from the exhaust pipe of inverter compressor 1 in sequence Connect the refrigerant side 4-expansion valve 3-evaporator 2, the outlet of the evaporator 2 is connected to the inlet of the inverter compressor 1, the refrigerant side 4 and the water side 6 are encapsulated in the condenser 5, and one end of the water side 6 is connected to the municipal water pipe 7. The other end is connected to the user water pipe 8, and a phase change heat storage device 9 is connected in parallel between the municipal water pipe 7 and the user water pipe 8, and a phase change heat storage material 10 is arranged in the phase change heat storage device 9, and the phase change heat storage The material 10 is provided with a plurality of heat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap