A kind of pcb board cable plug automatic assembly system and its assembly method

An automatic assembly, PCB board technology, applied in the direction of assembling printed circuits with electrical components, connecting/disconnecting connecting devices, etc. Balance and other issues to avoid sliding instability, ease wear and maintain balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

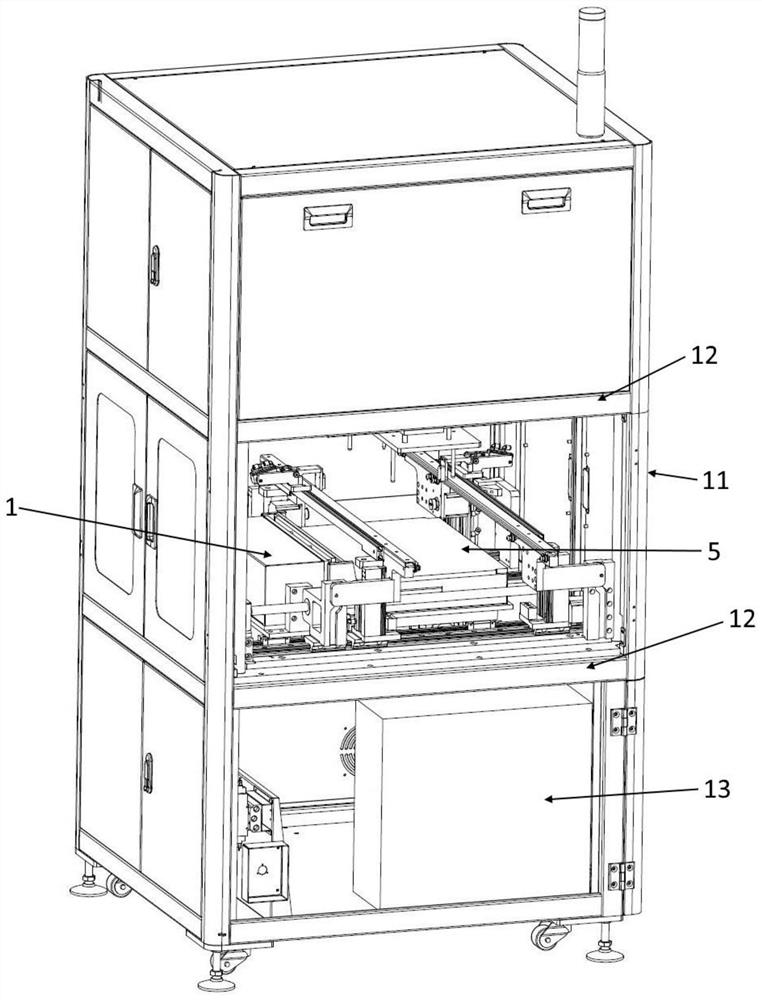

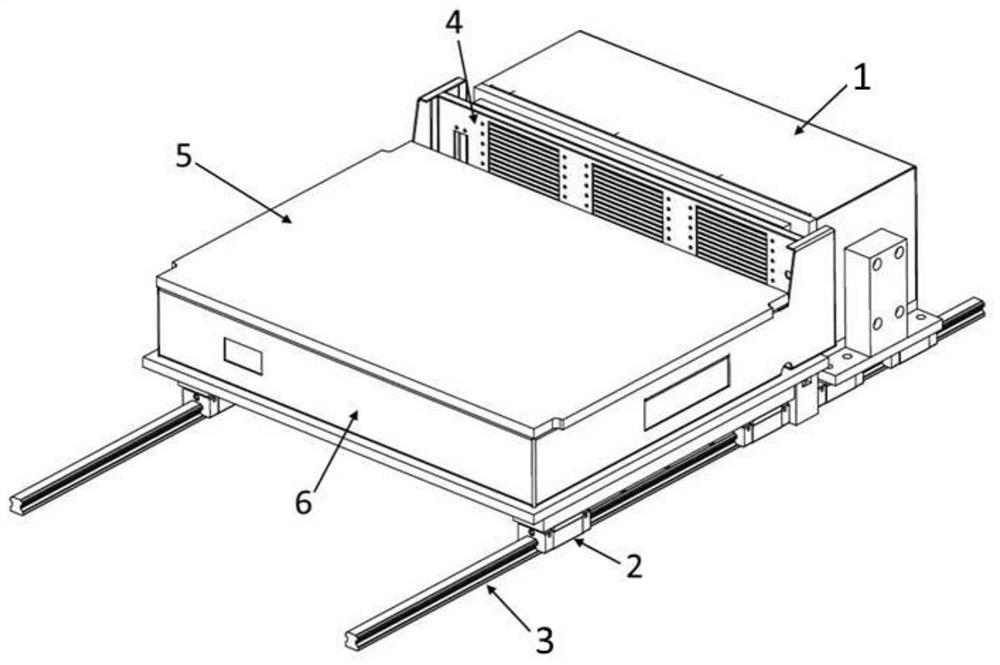

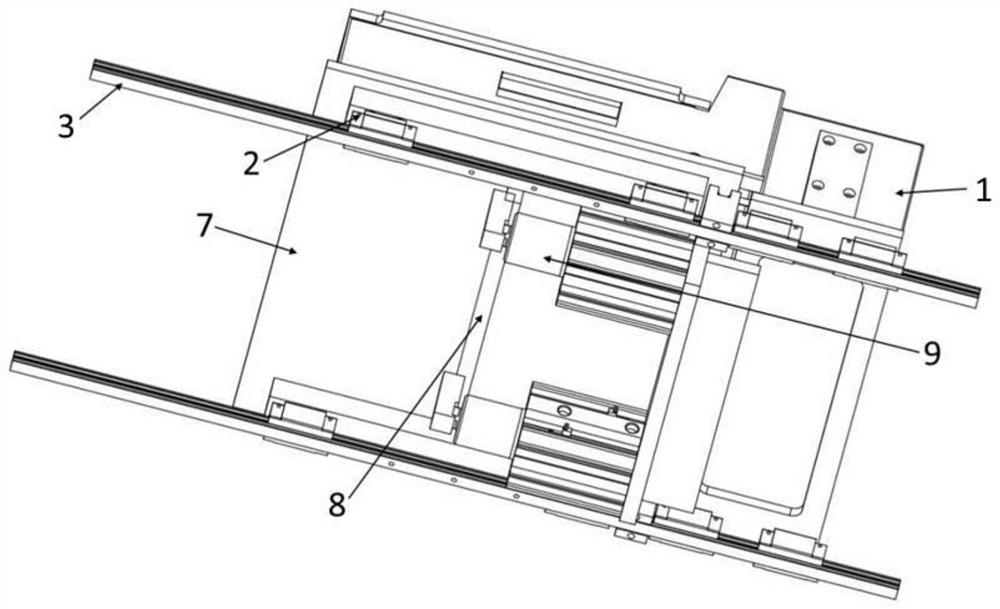

[0036] The invention relates to an automatic assembly system for PCB cable plugs, which includes three parts: a basic component, a control component, and an assembly component. The base assembly includes a frame 11, and a partition 12 that divides the frame into three parts, the upper, middle, and lower floors; the control assembly includes an air supply source 13 and a center console installed in the lower layer of the frame; the assembly assembly It includes a circuit board positioning mechanism and a circuit board pin mechanism 1 installed in the middle layer of the frame 11, and a movable pressing plate arranged above the circuit board positioning mechanism.

[0037] More specifically, the tooling fixture includes a support plate 6, an upper mounting plate 5 fixed on the upper part of the support plate 6, a needle plate 4 fixed on the side of the support plate 6, and a needle plate mounted on the support plate 6. , and the circuit board fixture 10 located at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com