Steam-water separator with water level control function

A steam-water separator and water level control technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as inability to control hot water water level, affect separator temperature, affect steam continuity, etc., and achieve steam quality The effect that does not decline, and improves the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

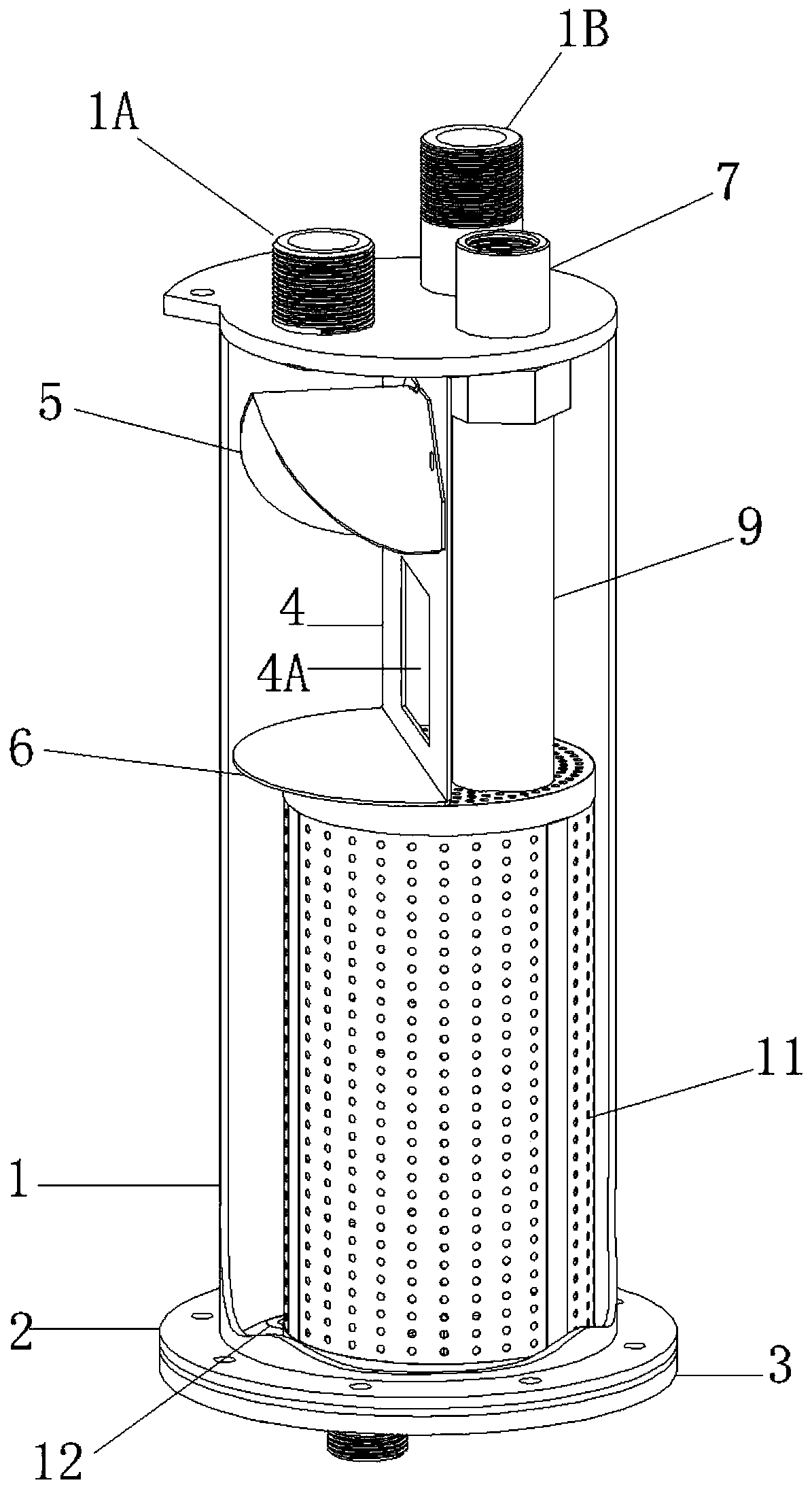

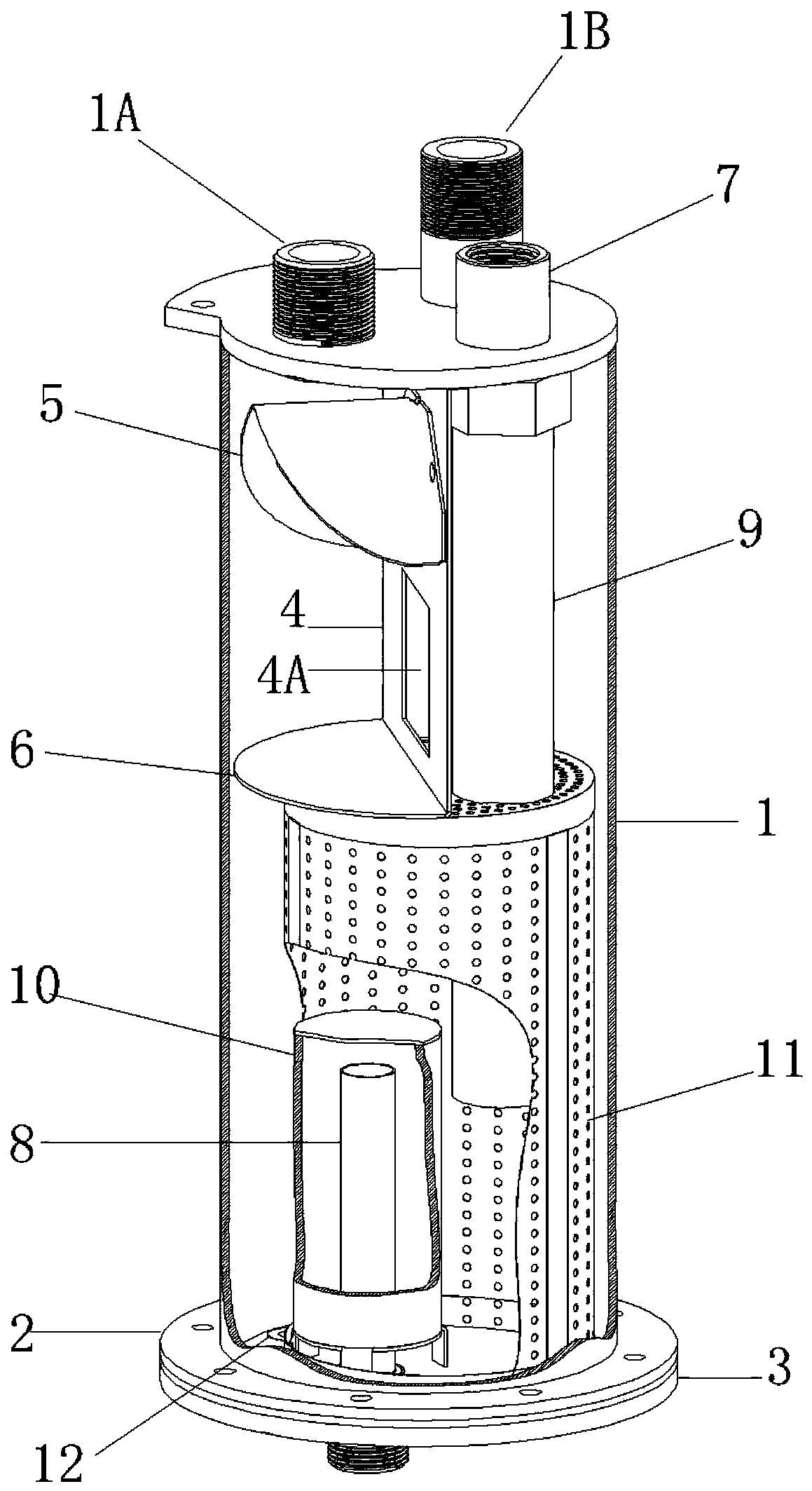

[0022] like Figure 1-2 As shown, a steam-water separator with water level control includes a hollow cylinder 1 with an open bottom, a flange 2 is provided at the bottom, and a bottom wall 3 is detachably and airtightly connected with the flange 2. The detachable structure is convenient Clean inside. The upper part of the inner chamber of the cylindrical body 1 is provided with a vertical partition plate 4 connected to its inner wall on three sides, and the vertical partition plate 4 divides the upper part of the inner chamber of the cylindrical body 1 into a steam inlet chamber and a steam outlet chamber. The top wall of the steam inlet chamber is provided with a steam inlet 1A, the top wall of the steam outlet chamber is provided with a steam outlet 1B, and the vertical partition plate 4 is provided with a square drainage hole 4A.

[0023] The steam inlet chamber is provided with a separation slant plate 5 opposite to the steam inlet 1A. The separation slant plate 5 is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com