Gripping-type part surface detection device

A technology for surface inspection and parts, which is applied in the field of grab-type parts surface inspection devices, can solve problems such as low efficiency of manual inspection, and achieve the effects of simple structure, reduced inspection cost, and improved inspection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following embodiments will describe the present invention in detail with reference to the drawings. In the drawings or descriptions, similar or identical parts use the same symbols, and in practical applications, the shape, thickness or height of each component can be enlarged or reduced. The various embodiments listed in the present invention are only used to illustrate the present invention, and are not intended to limit the scope of the present invention. Any obvious modifications or changes made to the present invention do not depart from the spirit and scope of the present invention.

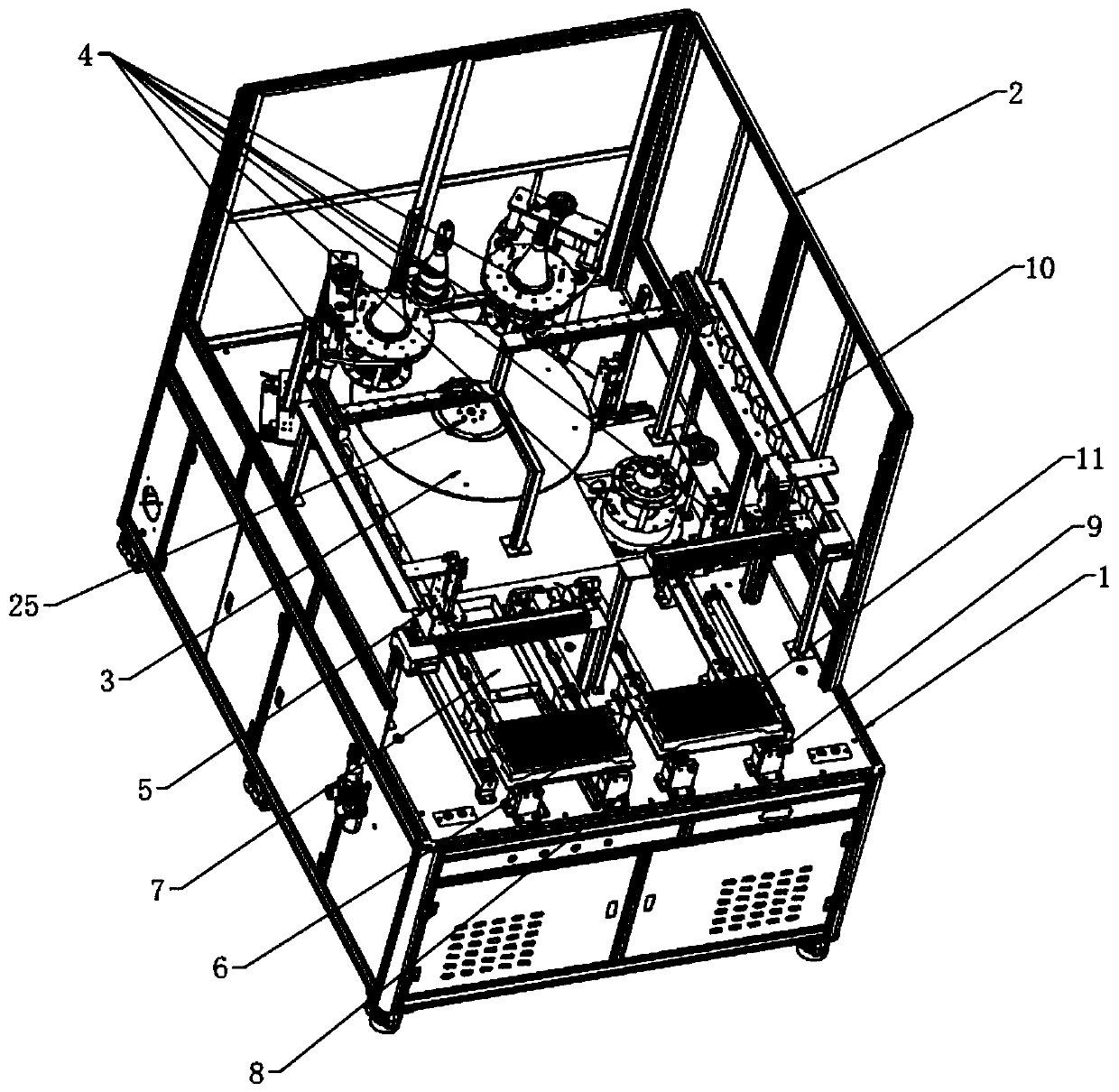

[0021] see Figure 1~3 , in an embodiment of the present invention, a grasping type part surface detection device includes a detection chassis platform 1, a detection mechanism for detecting the surface of a part, a grasping feeding mechanism and a grasping and unloading mechanism, and the detection mechanism includes The glass turntable 3 and a plurality of optical detection st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com