A chamfering jig and installation structure for a surface grinder

A surface grinding machine and installation structure technology, which is applied in the direction of grinding machines, parts of grinding machine tools, and machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of not being able to freely grind chamfering and chamfering fixtures, and achieve structural Simple, simple structure and installation structure, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

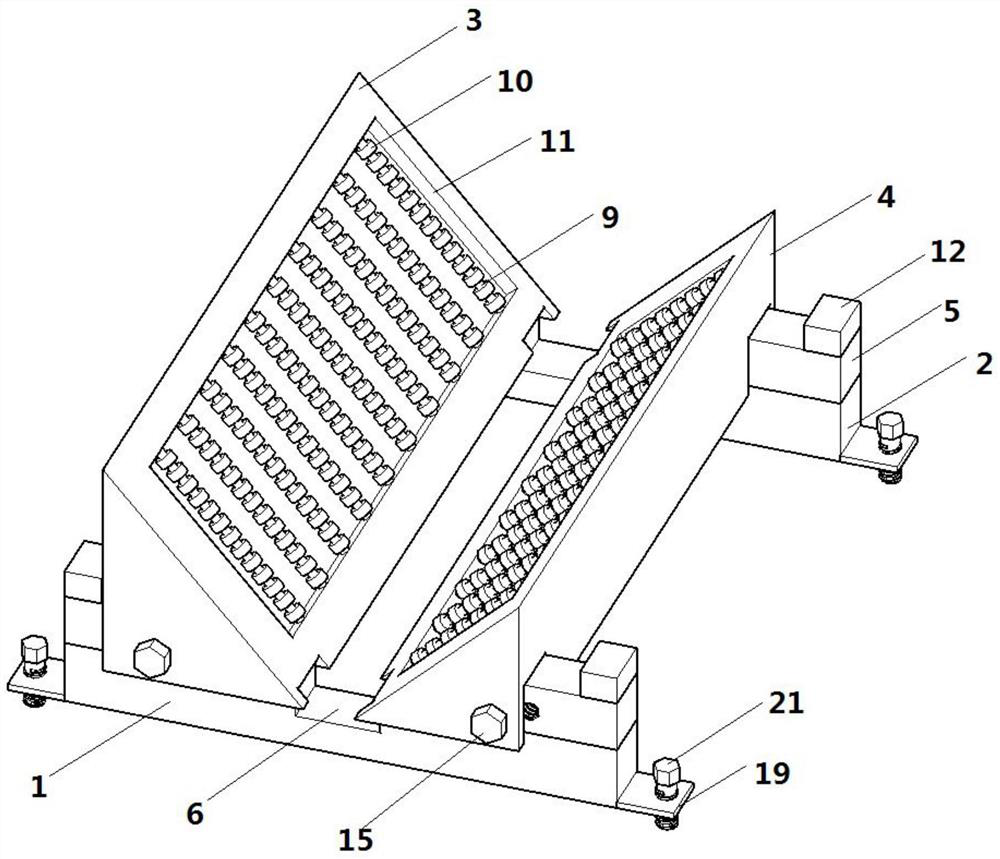

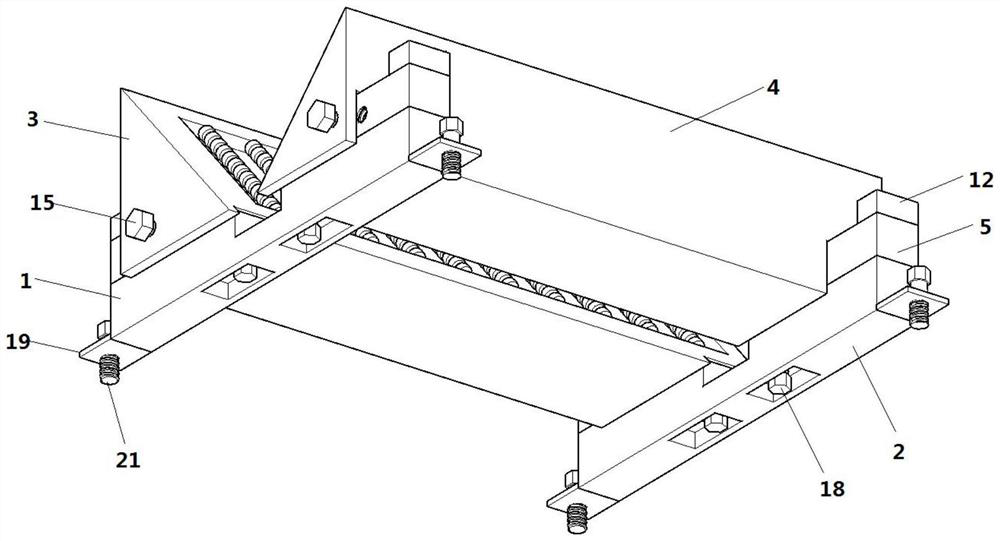

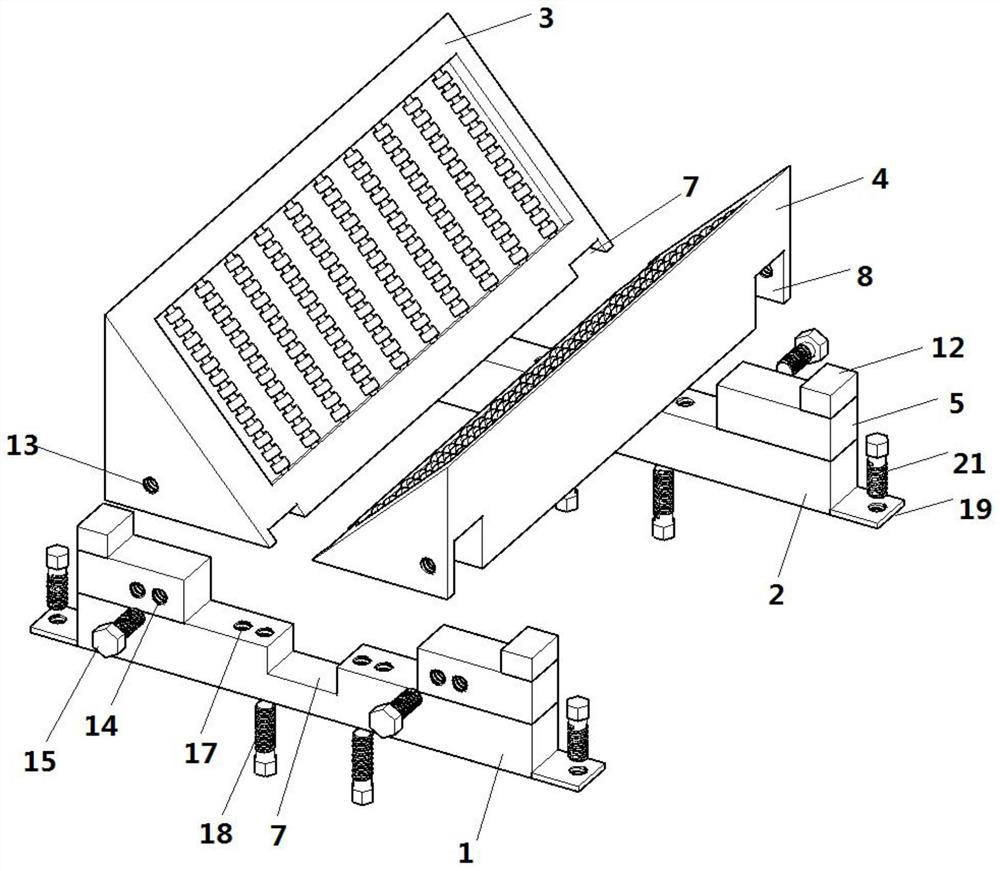

[0031] Such as Figure 1-Figure 4 As shown, a chamfering jig for a surface grinder includes a first positioning block 1, a second positioning block 2, a first positioning bevel 3 and a second positioning bevel 4, on the first positioning block 1 and the second positioning block 2 The left and right ends are all fixedly provided with fixed block 5, and all are provided with limit projection 12 at the end side of each fixed block 5 upper ends, and limit projection 12 can make the positioning inclined-plane can not come off when adjusting the position on the positioning block, the first Positioning block 1, the upper end of the middle part of the second positioning block 2 are provided with a square groove 6, the slopes of the first positioning slope 3 and the second positioning slope 4 are perpendicular to each other, and the rectangular object to be polished is placed on the first positioning slope 3 and the second positioning slope 4. Between the slopes of the positioning slop...

Embodiment 2

[0035] Such as Figure 1-Figure 4 As shown, a chamfering jig for a surface grinder includes a first positioning block 1, a second positioning block 2, a first positioning bevel 3 and a second positioning bevel 4, on the first positioning block 1 and the second positioning block 2 The left and right ends are all fixedly provided with fixed block 5, and all are provided with limit projection 12 at the end side of each fixed block 5 upper ends, and limit projection 12 can make the positioning inclined-plane can not come off when adjusting the position on the positioning block, the first Positioning block 1, the upper end of the middle part of the second positioning block 2 are provided with a square groove 6, the slopes of the first positioning slope 3 and the second positioning slope 4 are perpendicular to each other, and the rectangular object to be polished is placed on the first positioning slope 3 and the second positioning slope 4. Between the slopes of the positioning slop...

Embodiment 3

[0040] A chamfering jig for a surface grinder includes a first positioning block 1 , a second positioning block 2 , a first positioning slope 3 and a second positioning slope 4 .

[0041] Different from Embodiment 1 and Embodiment 2, the left and right ends of the first positioning block 1 and the second positioning block 2 are not provided with fixed blocks 5, and the slopes of the first positioning slope 3 and the second positioning slope 4 are perpendicular to each other. , the rectangular object to be polished is placed between the slopes of the first positioning bevel 3 and the second positioning bevel 4, the included angle of 90° is just the same as the grinding corner of the rectangular object to be polished, the first positioning bevel 3, the second The slope angle of the positioning slope 4 can also be other angles, which can be set according to the object to be polished. Grooves corresponding to the first positioning block 1 are provided on the bottoms of the first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com