Method for making biodegradable film

A production method and biological technology, applied in the field of biodegradable film production method, can solve the problems of easy rupture of the polymer film layer, loss of the competitive position of the solvent casting film method, and difficulty in peeling off the polymer film layer, so as to achieve good use. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] "Preparation of Polymer Prepolymer Coating Liquid"

[0068] Before using the solvent casting method to make biodegradable membranes, glycerol and various polyacids were used as raw materials in this experiment, and glycerol was reacted with various polyols to form polyester prepolymers. In order to facilitate the subsequent solvent casting method, in this experiment, an appropriate solvent was selected to be mixed with the polyester prepolymer to adjust the viscosity of the polyester prepolymer to obtain a polymer prepolymer coating solution that can be used in the subsequent process. .

[0069] The specific preparation method of the polymer prepolymer coating solution is exemplified as follows.

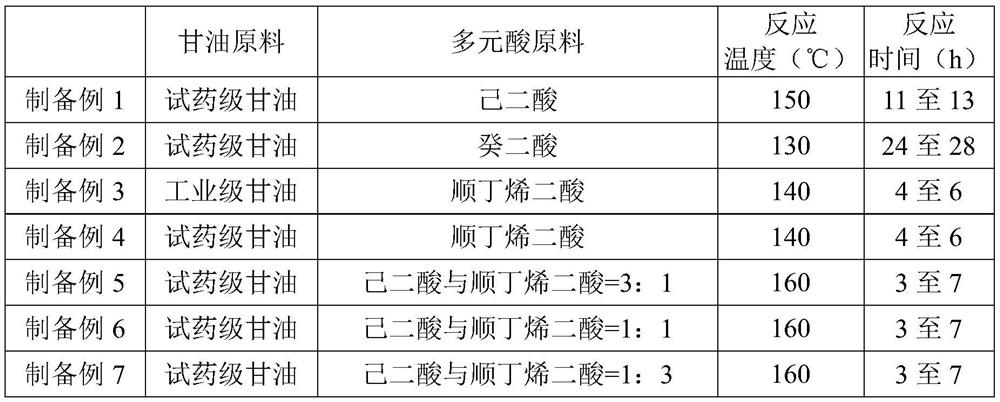

preparation example 1 to preparation example 7

[0070] Preparation Example 1 to Preparation Example 7: Polymer prepolymer coating liquid with acetone as solvent

[0071] Preparation Example 1 to Preparation Example 7 are basically the same method as described below to prepare polymer prepolymer coating solution, the difference lies in the types of glycerin and polybasic acid raw materials and the temperature and time parameters controlled in the polymerization reaction.

[0072] In the process, first weigh glycerol and polybasic acid whose molar ratio is 1:1, place it in a 1-liter double-neck flask continuously supplied with nitrogen, and then according to the reaction temperature and time shown in Table 1 below. A prepolymerization reaction is carried out to obtain a high molecular prepolymer. In Preparation Example 1 to Preparation Example 7, the glycerin used can be the above-mentioned technical grade glycerol or reagent grade glycerol, and the polybasic acid can be the above-mentioned adipic acid, sebacic acid, maleic a...

preparation example 8

[0078] Preparation Example 8: Polymer Prepolymer Coating Liquid Using THF as Solvent

[0079] The polymer prepolymer coating solution of Preparation Example 8 is roughly the same as the polymer prepolymer coating solution of Preparation Example 4, except that in Preparation Example 8, THF is used as a solvent to adjust the polymer prepolymer coating solution. The viscosity of the polymer prepolymer obtained in Preparation Example 4 and THF were mixed at a volume ratio of 1:0.25, and placed in an ultrasonic cleaner, heated at 60 ° C and shaken the mixed solution until The polymer prepolymer was completely dissolved in THF; and then stirred with a magnet for 24 hours to ensure that it could be completely dissolved and uniformly dispersed to obtain the polymer prepolymer coating solution of Preparation Example 8 (viscosity about 45000cp).

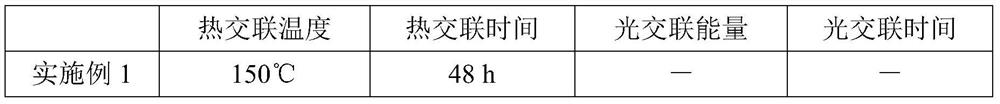

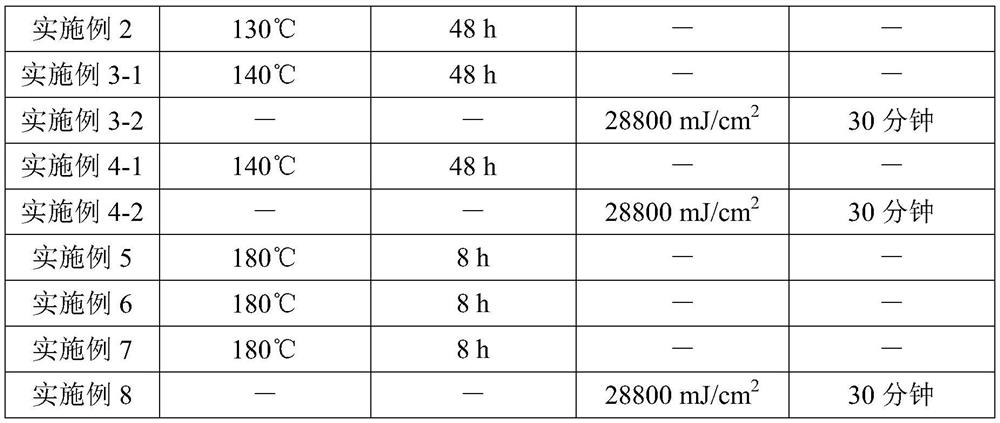

[0080] "Preparation of Biodegradable Films"

[0081] In order to improve the many problems derived from the previous solvent casting method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com