Immersed tube structure applicable to high flow velocity and construction method thereof

A construction method and high-velocity technology, applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problem of increased installation time of immersed tubes, inability to control the accuracy of sinking within a suitable range, and easy swaying of immersed tubes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

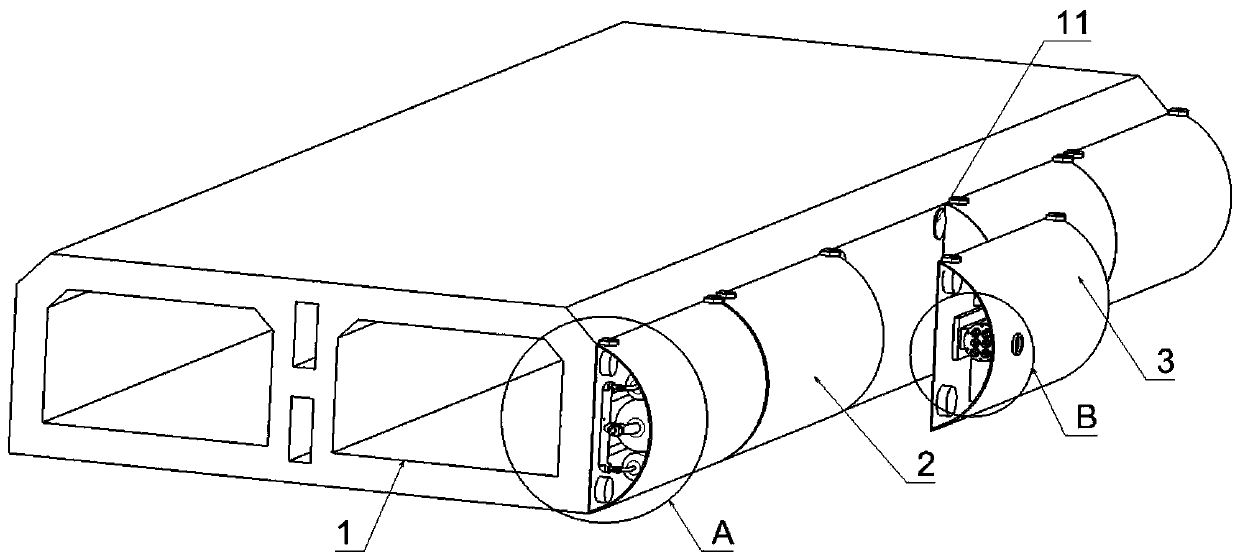

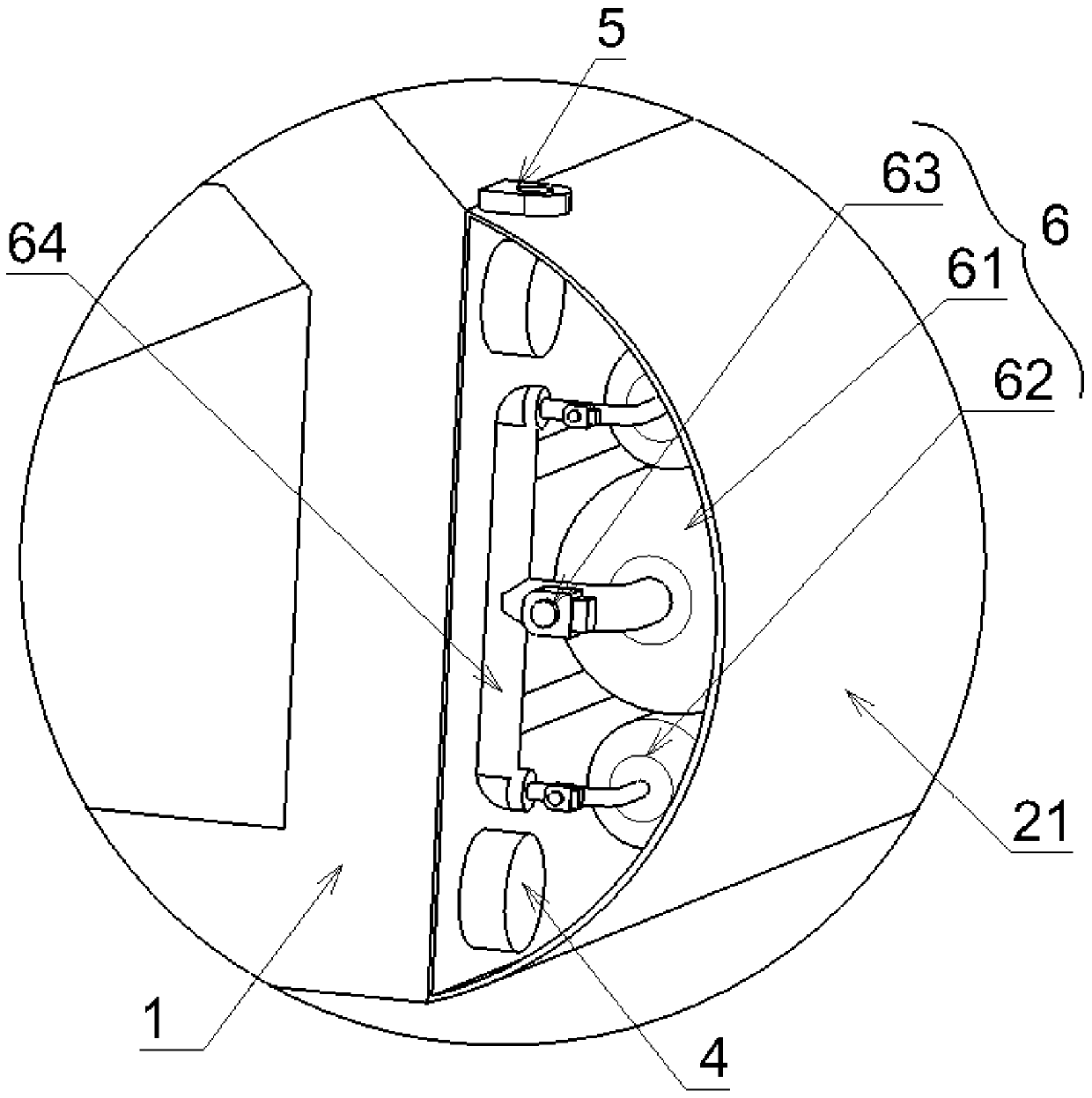

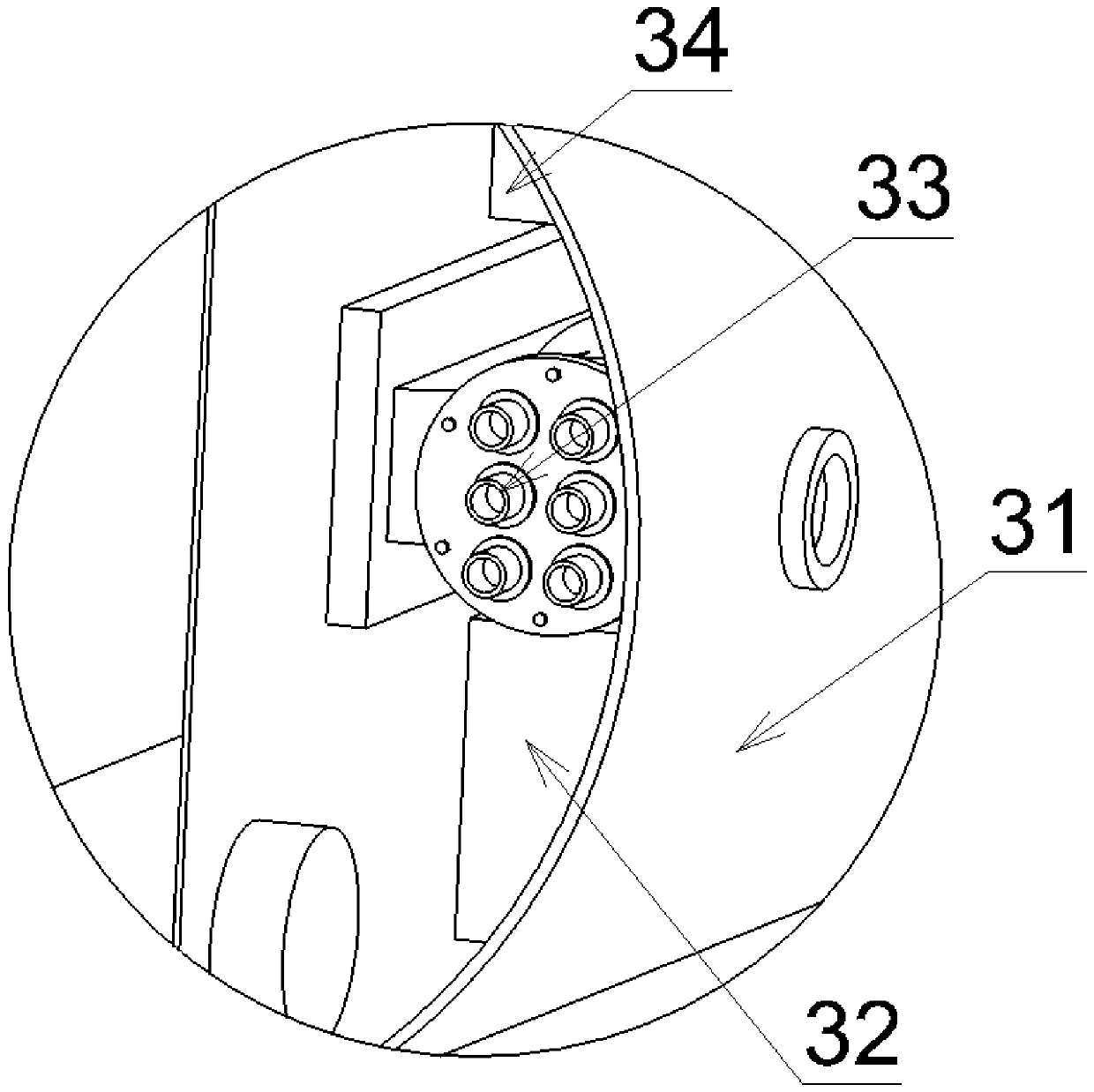

[0024] Such as figure 1 As shown, an immersed tube structure suitable for high flow rate provided in this embodiment includes an immersed tube body 1, and a channel for opening to traffic is arranged in the immersed tube body 1, and one side of the immersed tube body 1 is along the The longitudinal direction is provided with several shrouds 2, the outer side of the shroud 2 is provided with an elastic capsule body 21, each of the shrouds 2 is provided with a protrusion control device 6 inside, and the protrusion control device 6 will The elastic capsule body 21 is propped up to control the protrusion degree of the elastic capsule body 21, and the protrusion degree of each of the shrouds 2 can be adjusted individually. The side of the traditional immersed tube is generally a plane, and the water flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com