30-rod spherical tension whole movable structure

A technique of tensioning the whole structure and tensioning the whole, applied in the direction of special structures, building components, etc., to achieve the effect of improving the stability of movement, ensuring self-plasticity and stability, and improving the flexibility of path selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

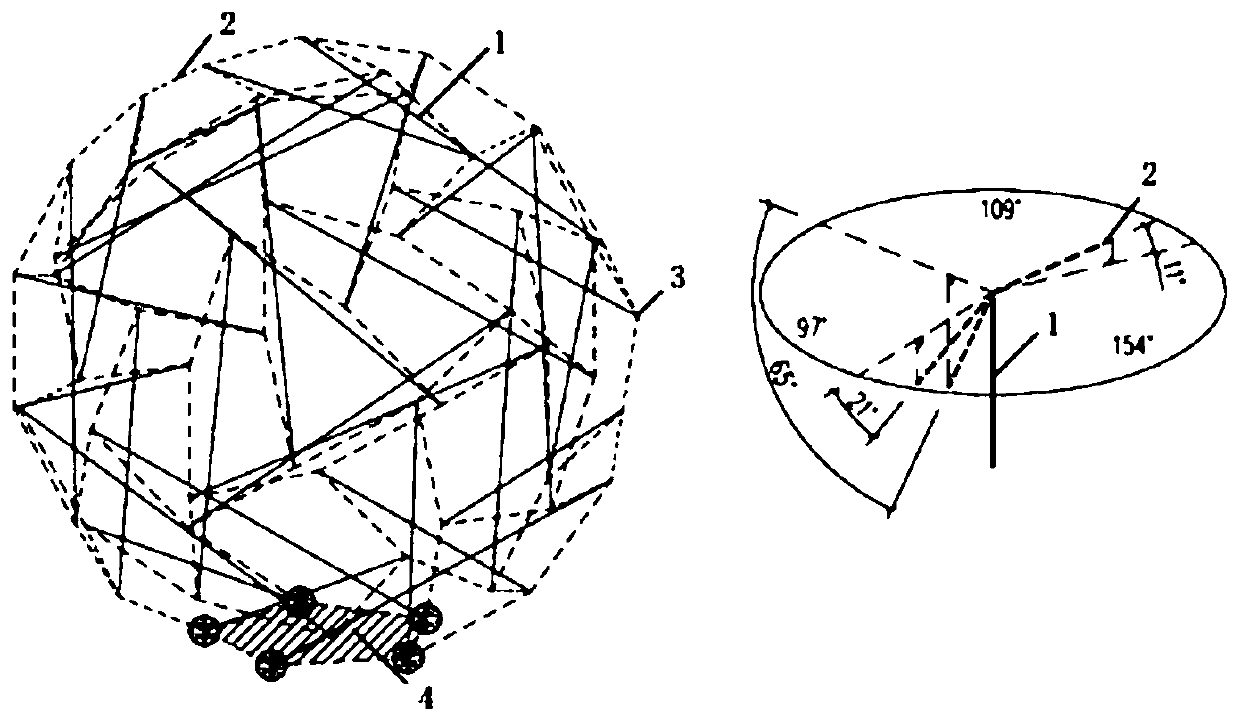

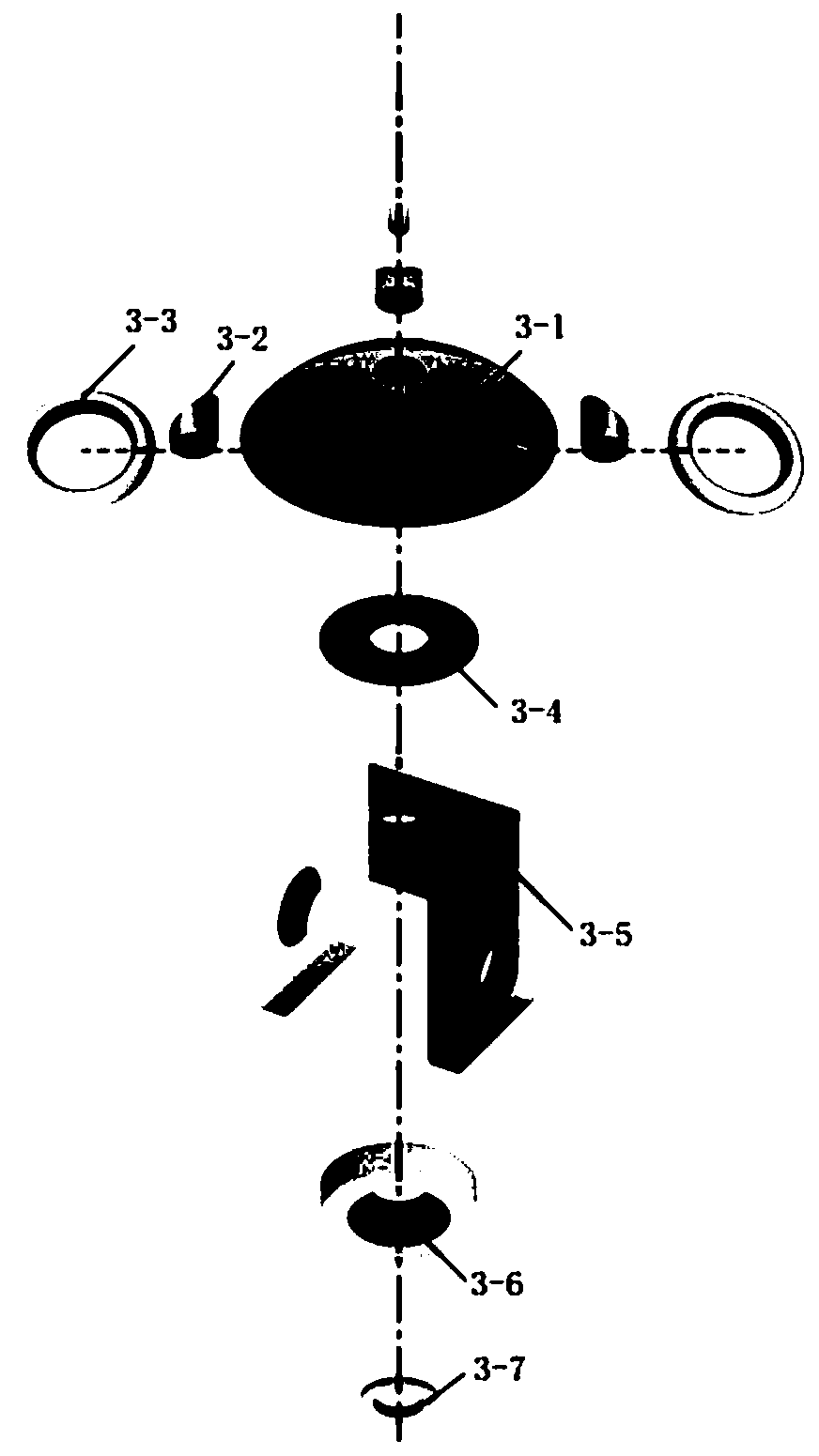

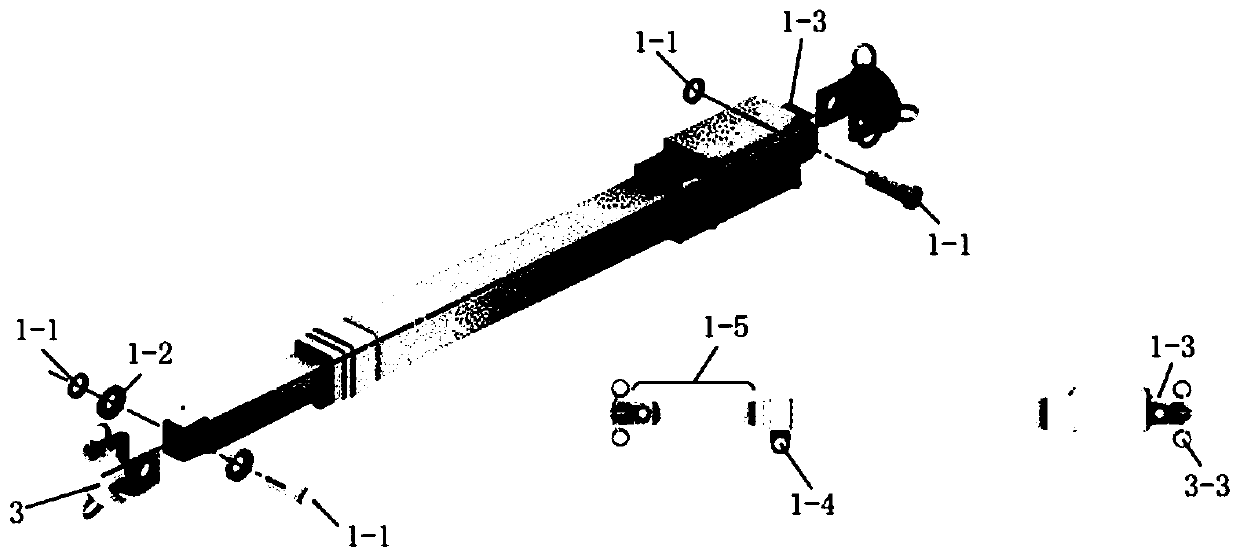

[0036] Both the compression rod and the cable of the 30-rod spherical tension integral movable structure described in the present invention can be used as actuators (active components) for driving strategy input, so as to realize the marching motion mode of the structure. In the following specific implementation schemes, the driving of the pressing bar by a driver such as a motor is an example, and there are two types of driver center control scheme and driver distribution control scheme, and the reference length of the pressing bar (the distance between the two ends of the pressing bar in the bar system model) L is selected. b = 206mm. At the same time, on the basis of the main structure, the design of the fixing method of the control system is introduced, and the implementation steps of the structure and the driving strategy of the travel mode driven by the pressure rod are elaborated in detail.

[0037] Such as figure 1 As shown, the 30-rod tensegrity body structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com