Use method of high temperature and high pressure steam energy saving mixing

A high-temperature, high-pressure, steam technology, which is applied in steam applications, steam engine devices, machines/engines, etc., can solve the problems of short service life of valves, large energy loss, and increased steam cost, so as to save maintenance costs and reduce losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for using high-temperature and high-pressure steam energy-saving mixing, comprising the following steps:

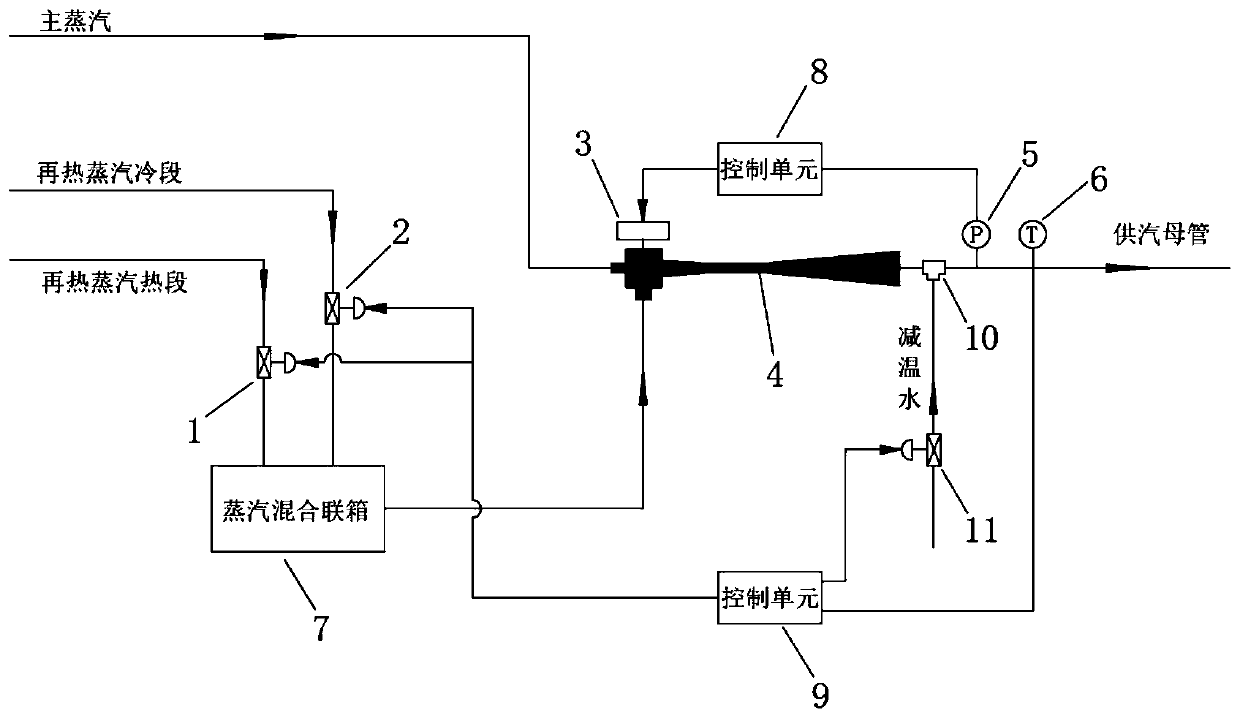

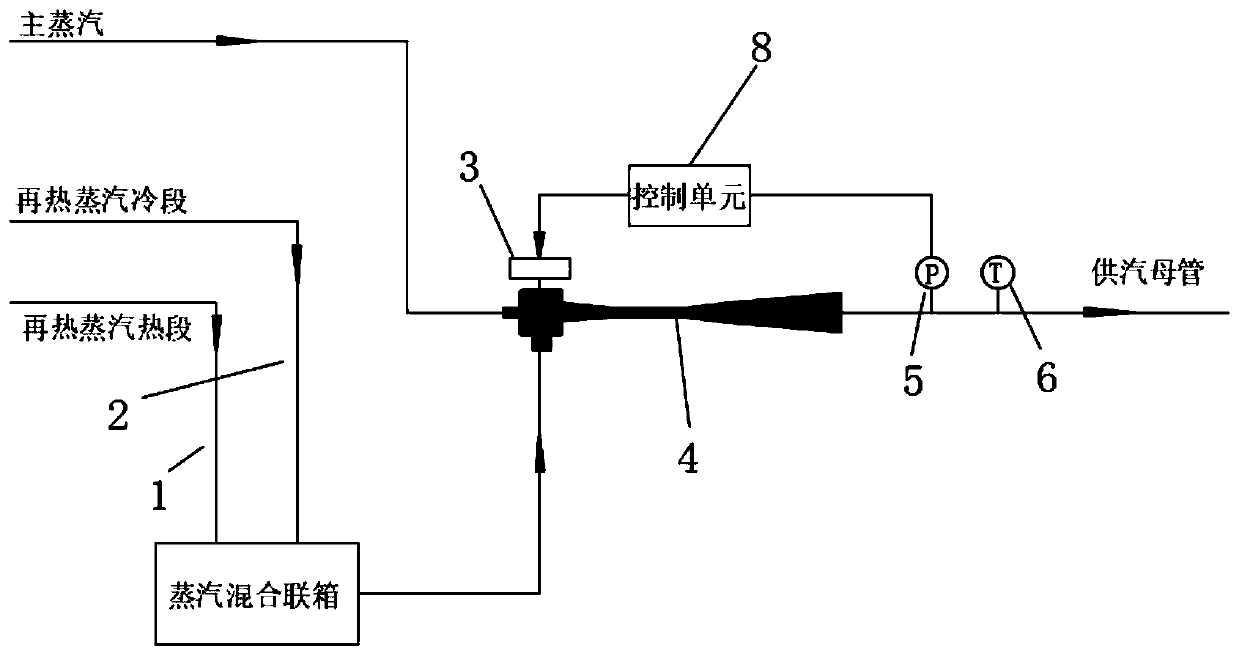

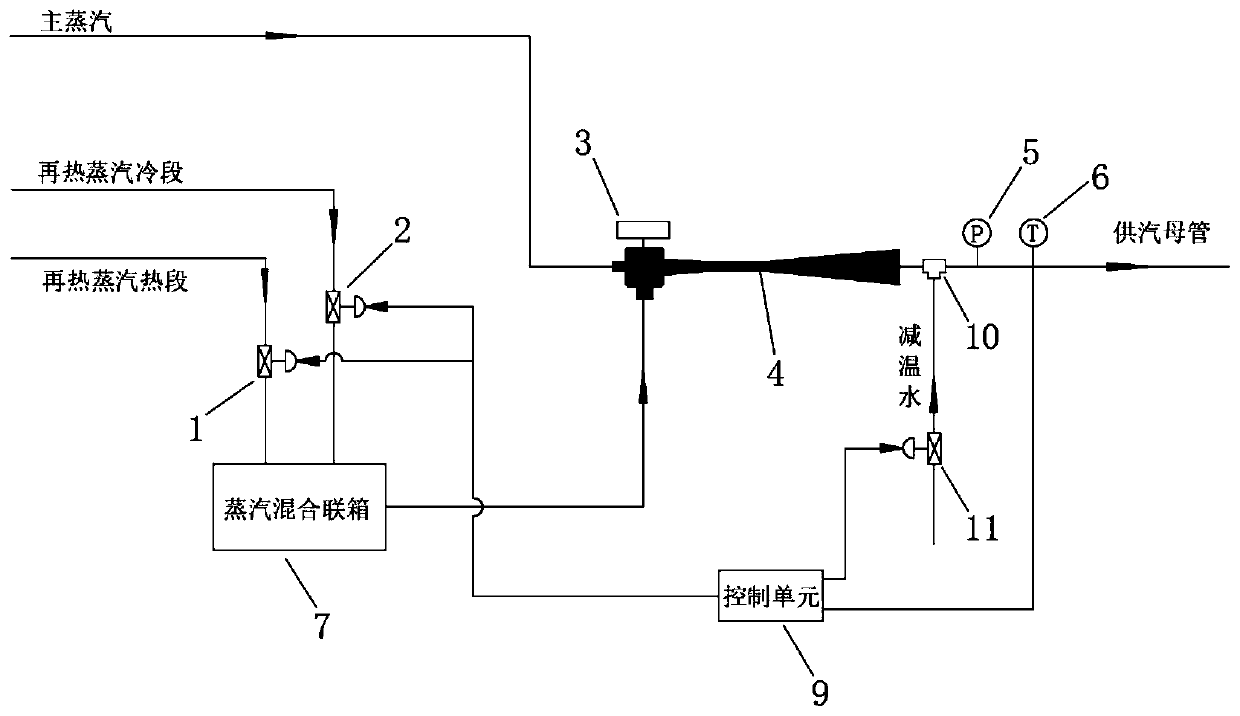

[0033] S1, using main steam as power steam, injecting cold / hot remixed steam from the steam mixing header 7, and mixing through the ejector 4;

[0034] S2. During the mixing process in step S1, when the unit load changes, the steam pressure will also change accordingly. At this time, the pressure signal of the pressure transmitter 5 at the outlet of the injector 4 is sent to the injector 4 as a feedback signal After that, the first control unit 8 issues instructions to adjust the adjustable actuator 3 of the injector 4, change the throat flow area of the injector 4, and change the flow rate of the injected steam; thus ensuring that the injector 4 The outlet pressure is stable at the value required by the user;

[0035] S3. After the pressure at the outlet of the injector 4 is stabilized at the value required by the user, the outlet of the injector 4 ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com