Self-adaptive gas regulator for semi-automatic shotgun

A regulator and self-adaptive technology, applied in the field of firearms, can solve problems such as uncomfortable shooting experience, limit the interchangeability of regulators, and many shooting failures, so as to increase shooting comfort, improve shooting comfort, and improve shooting fun. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

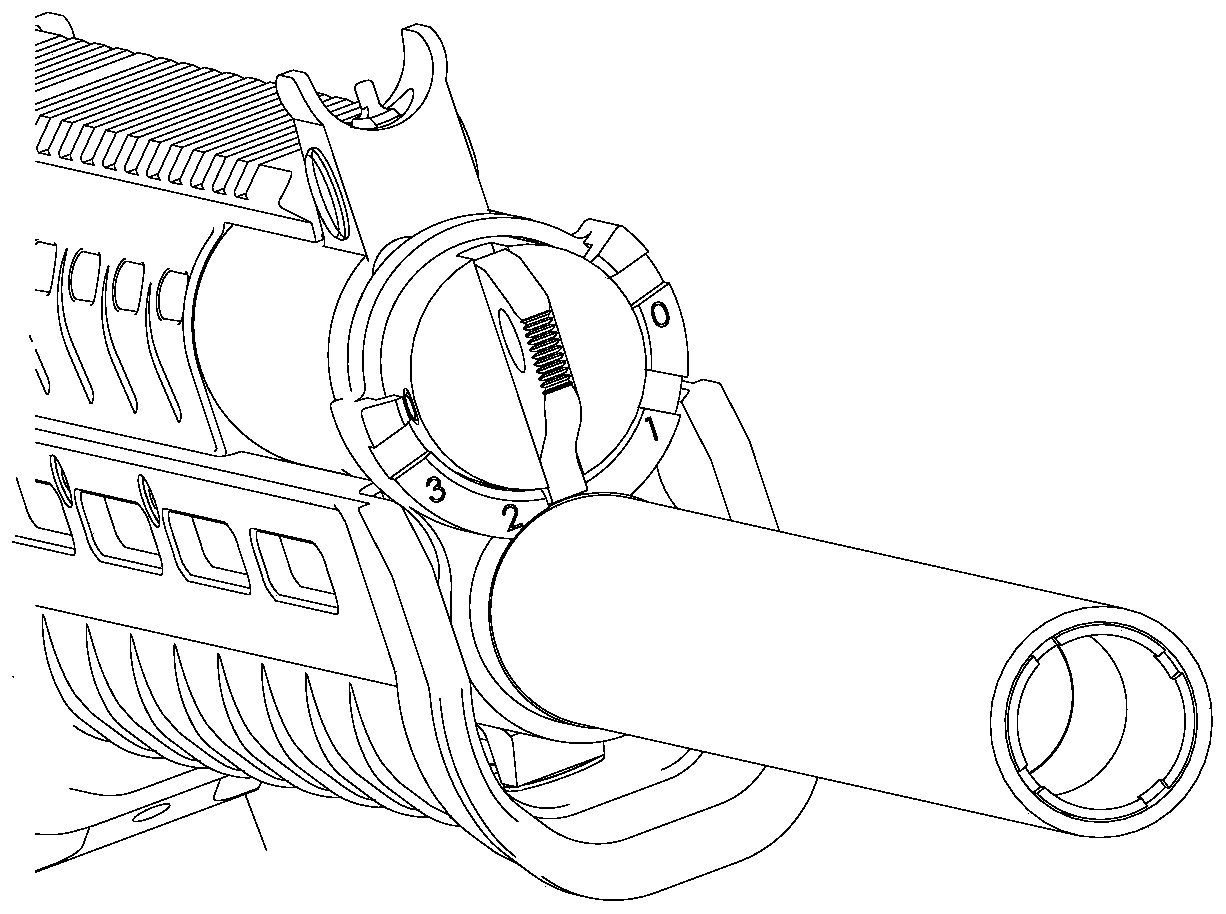

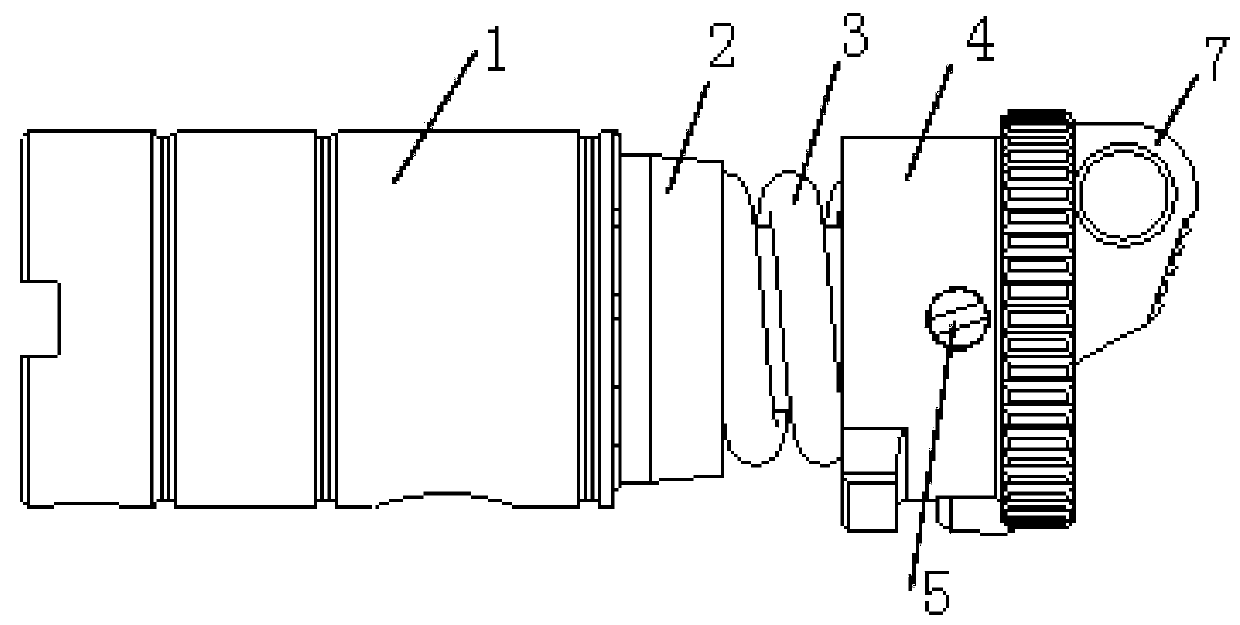

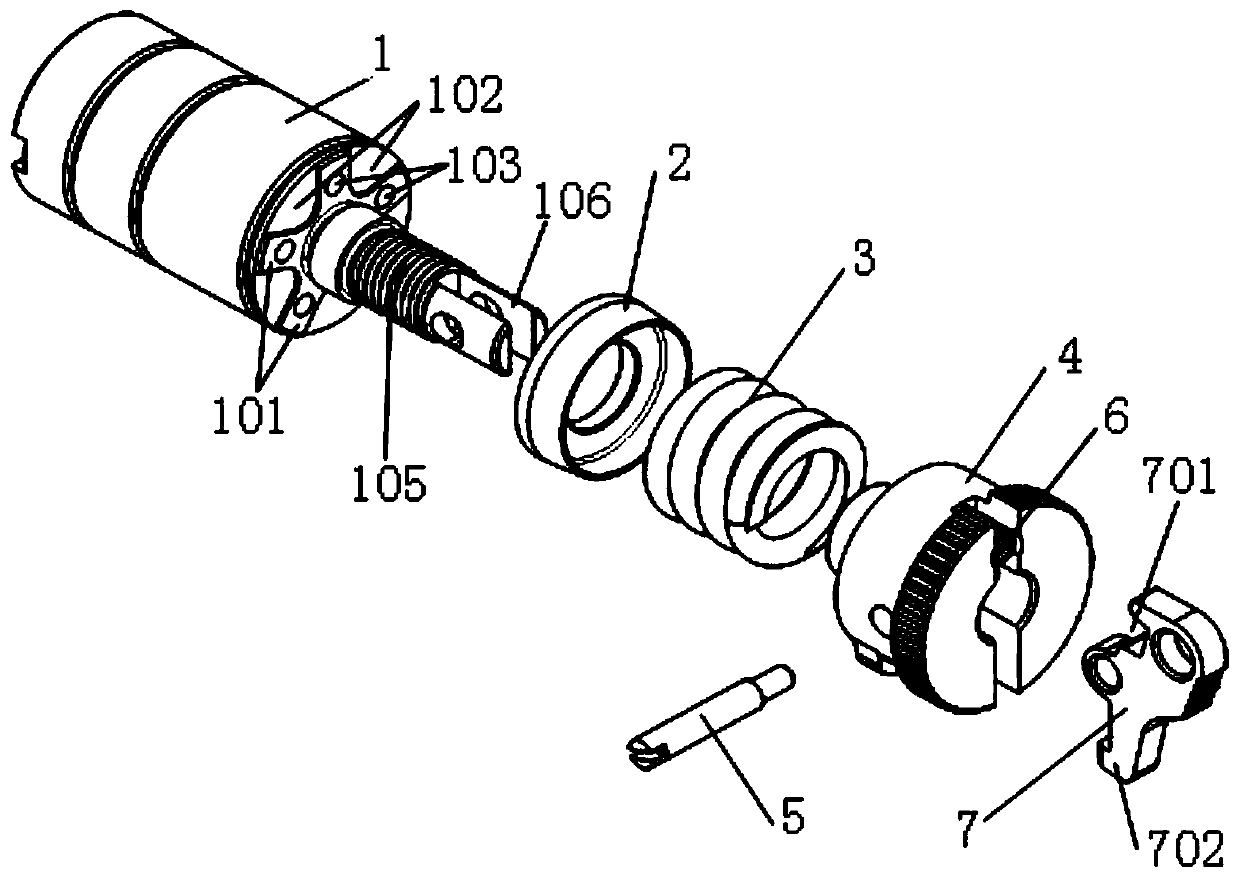

[0026] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] Taking the gun barrel 8 shooting direction as the front end among the present invention.

[0028] see Figure 2-Figure 7 As shown, an embodiment of an adaptive gas regulator for a semi-automatic shotgun includes a regulator body 1. A cavity 104 is provided inside the regulator body 1 to cooperate with a piston 10 in the gun body. An air chamber 12 is formed between the body 1, which communicates with the air guide hole of the regulator body and the air guide hole 11 of the gun barrel, and also includes a sealing gasket 2, a sealing spring 3, a spring seat 4 and a positioning block 7. The front end of the regulator body 1 The large end of the large end is provided with a protrusion outwardly to form a gas-closing surface 101, and a number of exhaust holes 103 are uniformly distributed in the axial direction on the gas-closing surface 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com