Disc type permanent magnet motor applied to crane

A technology for permanent magnet motors and cranes, applied in electromechanical devices, emergency power supply arrangements, magnetic circuits, etc., can solve the problems of reduced service life of motors, complex structure of cranes, and inaccurate positioning, so as to avoid the impact of frequent jogging and save energy. Electric energy and material cost, effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

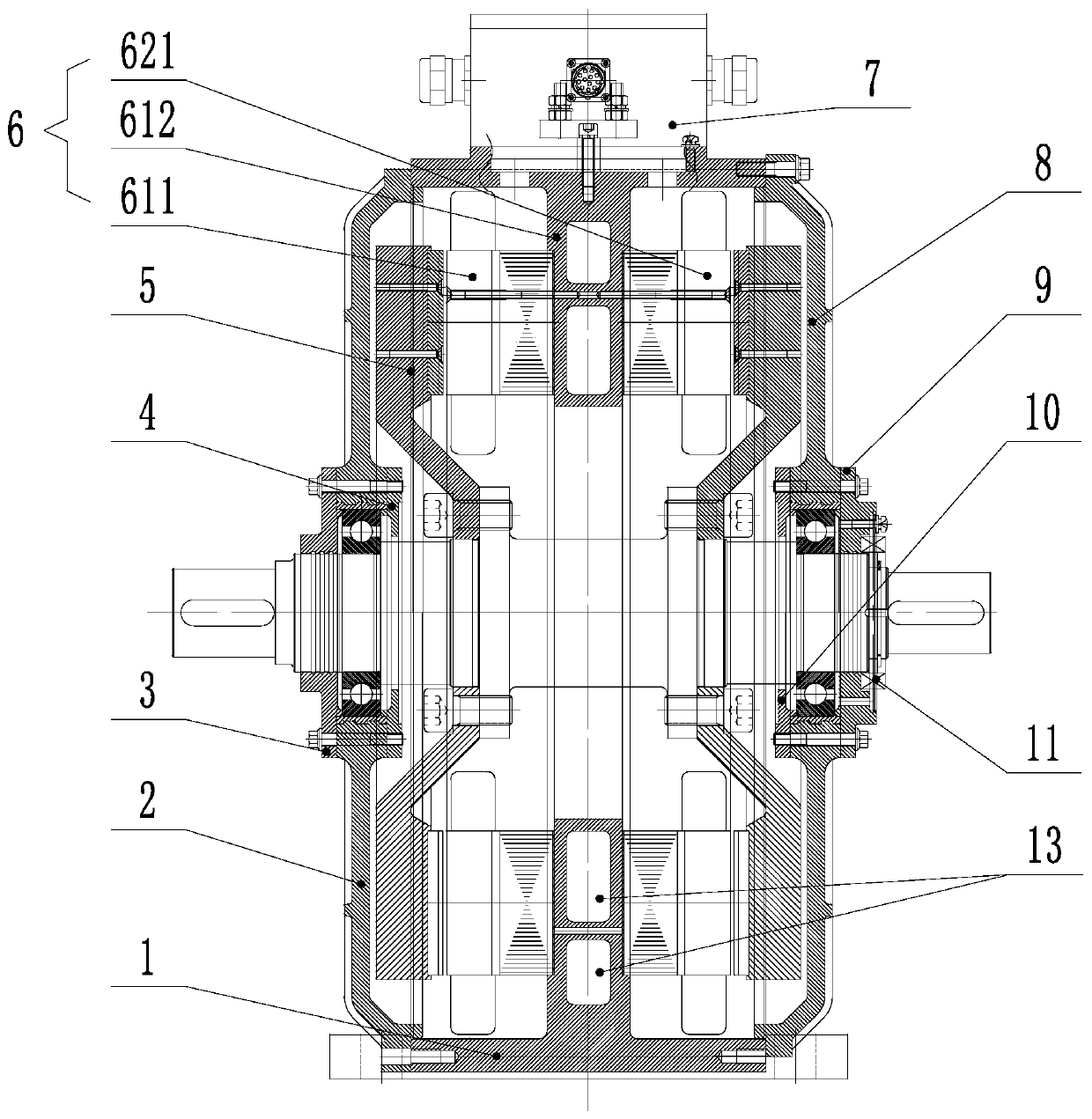

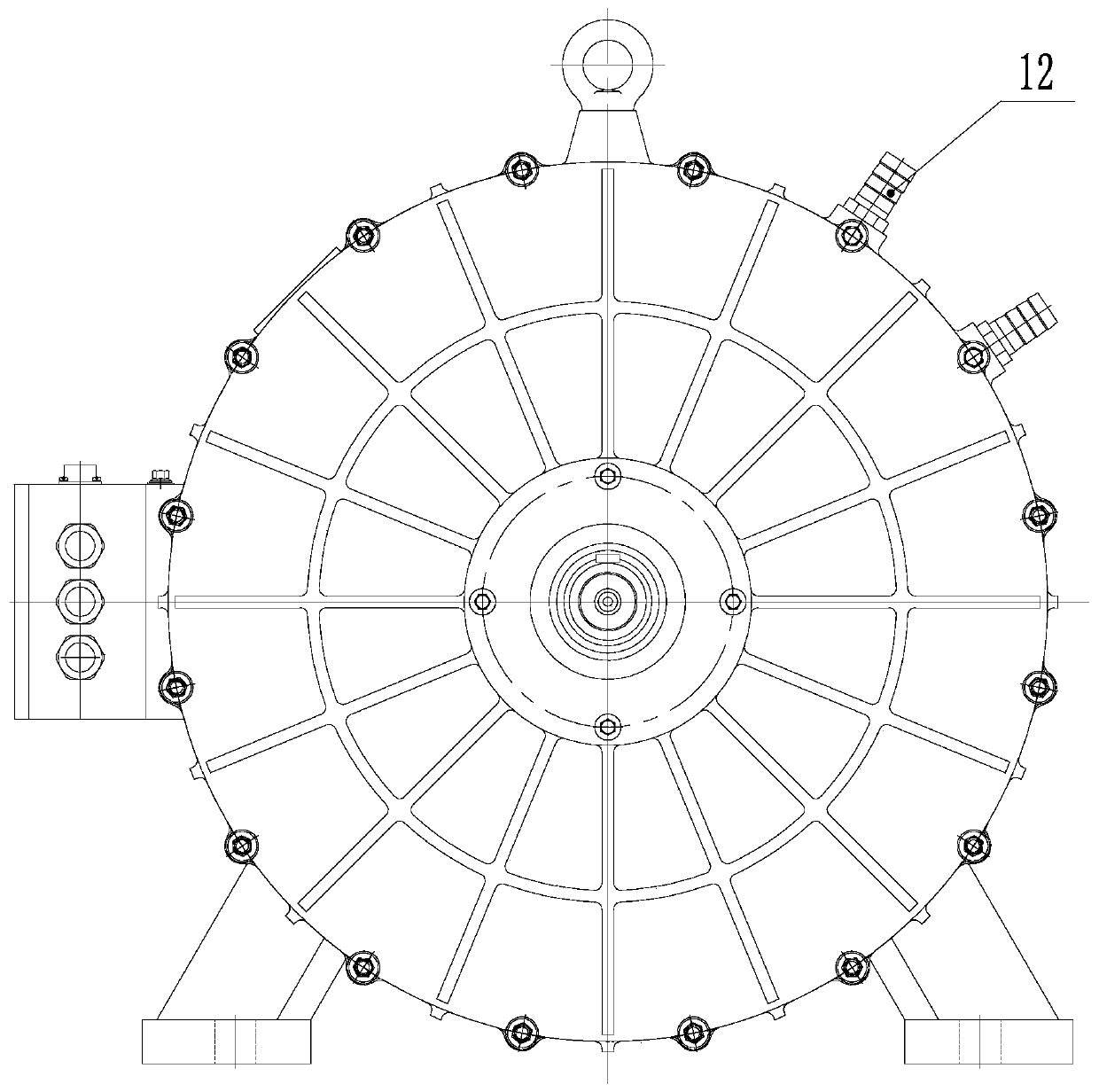

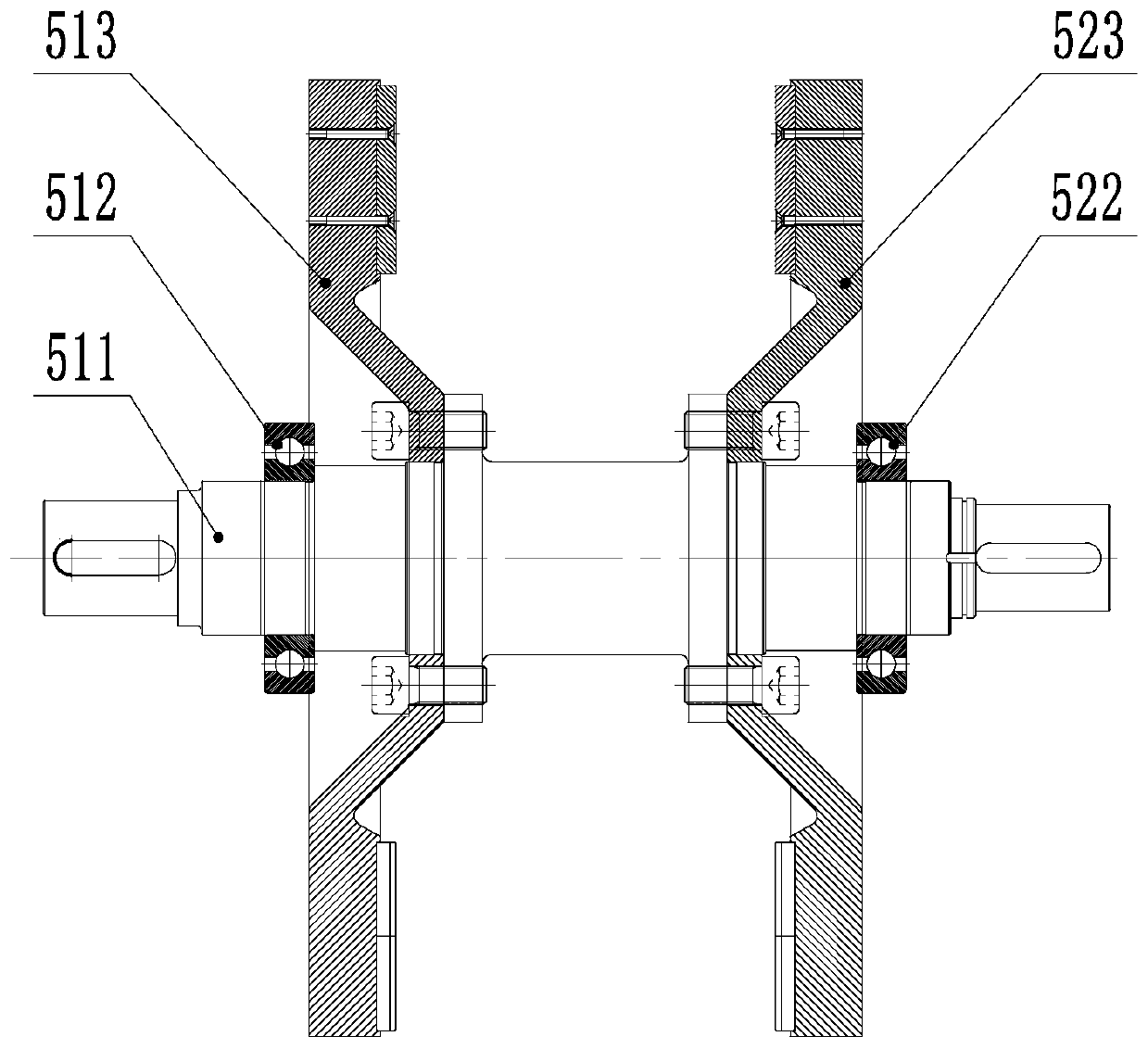

[0034] like Figure 1-Figure 7 As shown, a disc permanent magnet motor applied to a crane includes a casing set, a motor shaft 511, a rotor assembly 5 and a stator assembly 6, and the number of groups of the rotor assembly 5 is the same as the number of groups of the stator assembly 6 Equal and greater than or equal to 2. The casing set surrounds a hollow cavity, the motor shaft 511 passes through the casing set horizontally, and is rotatably connected with the casing set, and the motor shaft 511 is located on the casing The outside of the kit is provided with a double output shaft extension structure for transmission; the stator assembly 6 is located in the cavity of the casing kit and is fixedly connected with the casing kit, and the stator assembly 6 is connected to the motor shaft 511 There is a radial gap between the circumferences, and the rotor assembly 5 is fixed on the motor shaft 511, and the rotor in the rotor assembly 5 is matched with the stator in the stator ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com