Casting furnace hole plugging device

A technology of furnace plug and furnace eye, which is applied in the field of casting furnace plug introduction device, can solve the problems of poor blocking effect, time-consuming and labor-intensive application, etc., and achieves hard texture, simple and convenient operation, and good blocking effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

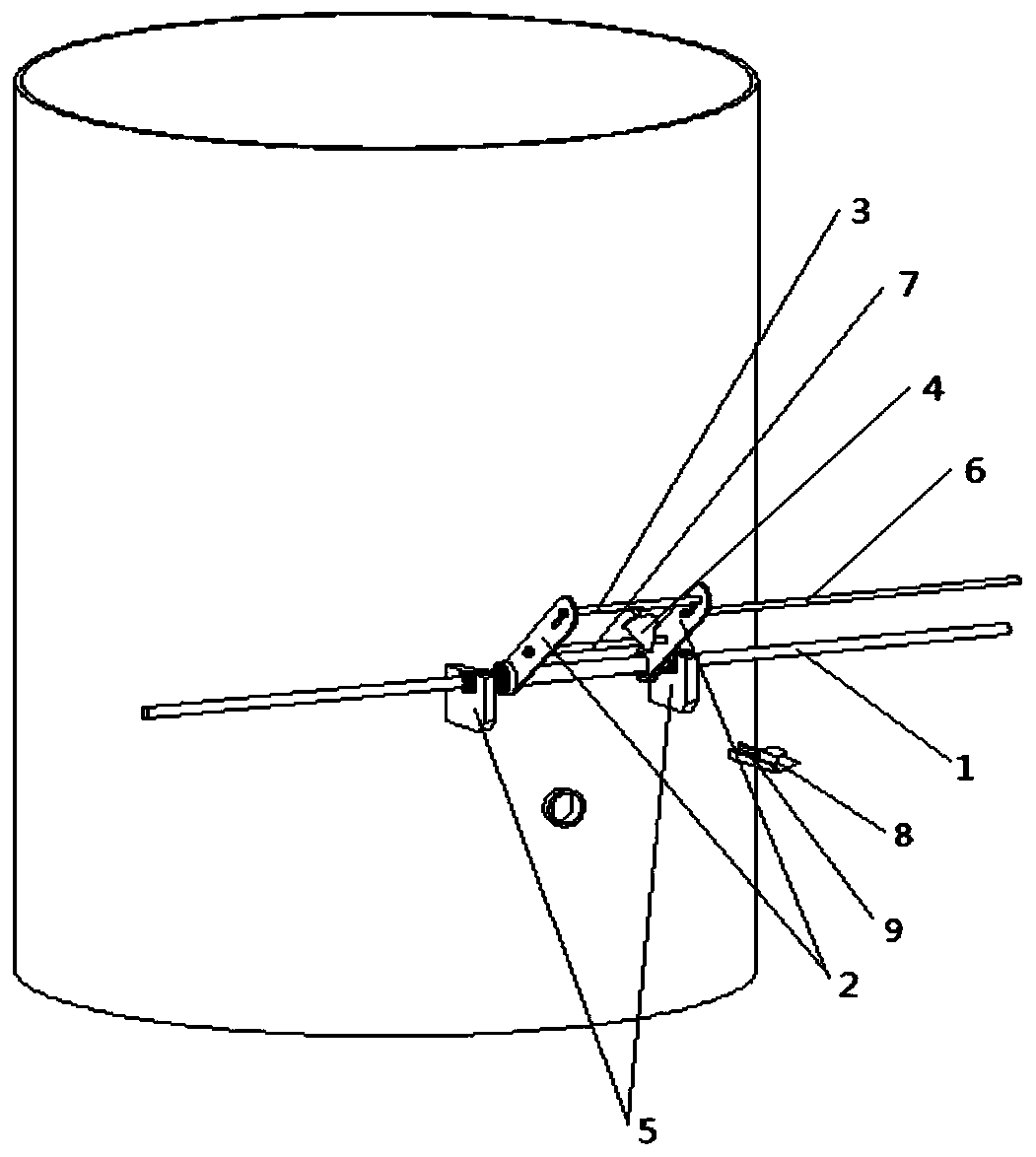

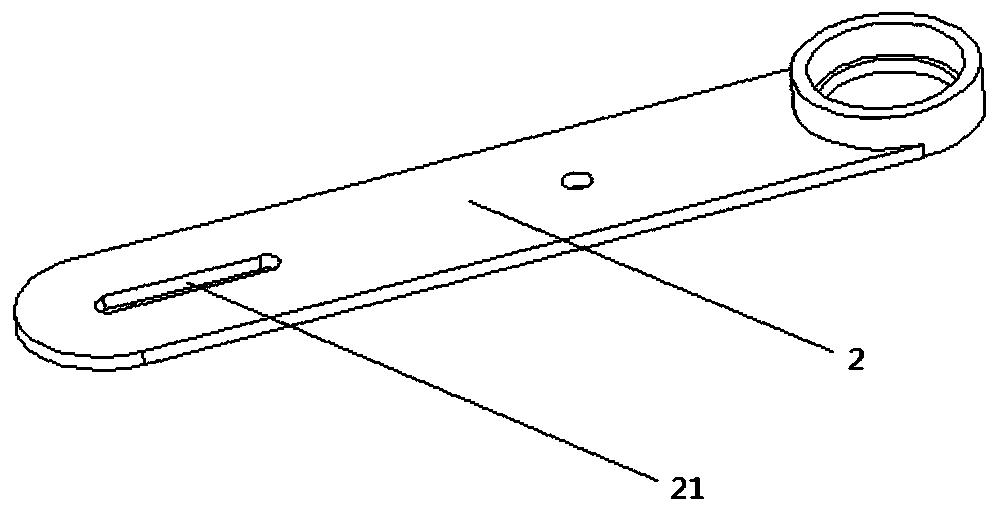

[0028] Such as figure 1 As shown, a casting furnace plug introduction device includes a main shaft 1, two connecting plates 2 and a limit block 8, the bottom of the connecting plate 2 is rotatably mounted on the main shaft 1, and the tops of the two connecting plates 2 are provided with a waist Circular adjustment groove 21, such as figure 2 As shown; the two ends of the installation rod 3 pass through the adjustment groove 21 and are connected to the connection plate 2 respectively, the installation rod 3 is connected with the tapered plug 4, the support rod 7 is arranged between the two connection plates 2, and its two ends are respectively It is connected to the connecting plate 2 through M8 nuts, the support rod 7 is set in the middle position between the main shaft 1 and the installation rod 3, the operating rod 6 is connected to the outside of the connecting plate 2 through M8 nuts, and the bracket 5 is fixed on the outer side of the casting furnace wall. In the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com