Butt joint type weld joint feature point identification method and device, equipment and storage medium

A weld feature and recognition method technology, applied in the field of image recognition, can solve the problems affecting the extraction of weld feature points, poor welding tracking effect, etc., to achieve the effect of eliminating interference and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

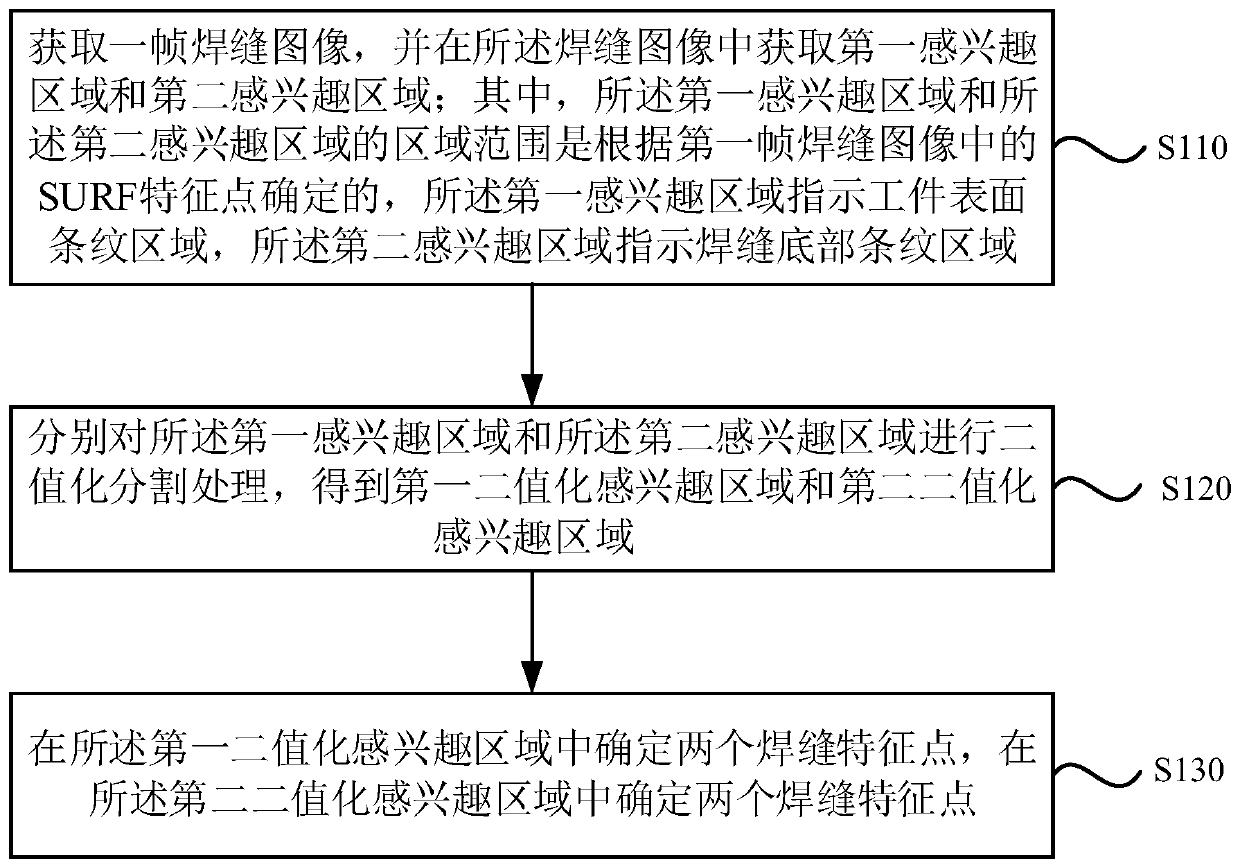

[0025] figure 1 It is a flow chart of a method for identifying feature points of a butt-type weld provided in Embodiment 1 of the present invention, which is applicable to various disturbances such as arc light, spatter, and metal reflection in welding field applications, so that the butt-type (such as V-type) 口) In the case that errors may occur in the identification of weld feature points, the method can be performed by the identification device for butt-type weld feature points provided in the embodiment of the present invention, which can be implemented in software and / or hardware, and generally It can be integrated in the welding seam image acquisition equipment (including processor).

[0026] Such as figure 1 As shown, the method of this embodiment specifically includes:

[0027] S110. Acquire a frame of weld image, and acquire a first region of interest and a second region of interest in the weld image; wherein, the area ranges of the first region of interest and the s...

Embodiment 2

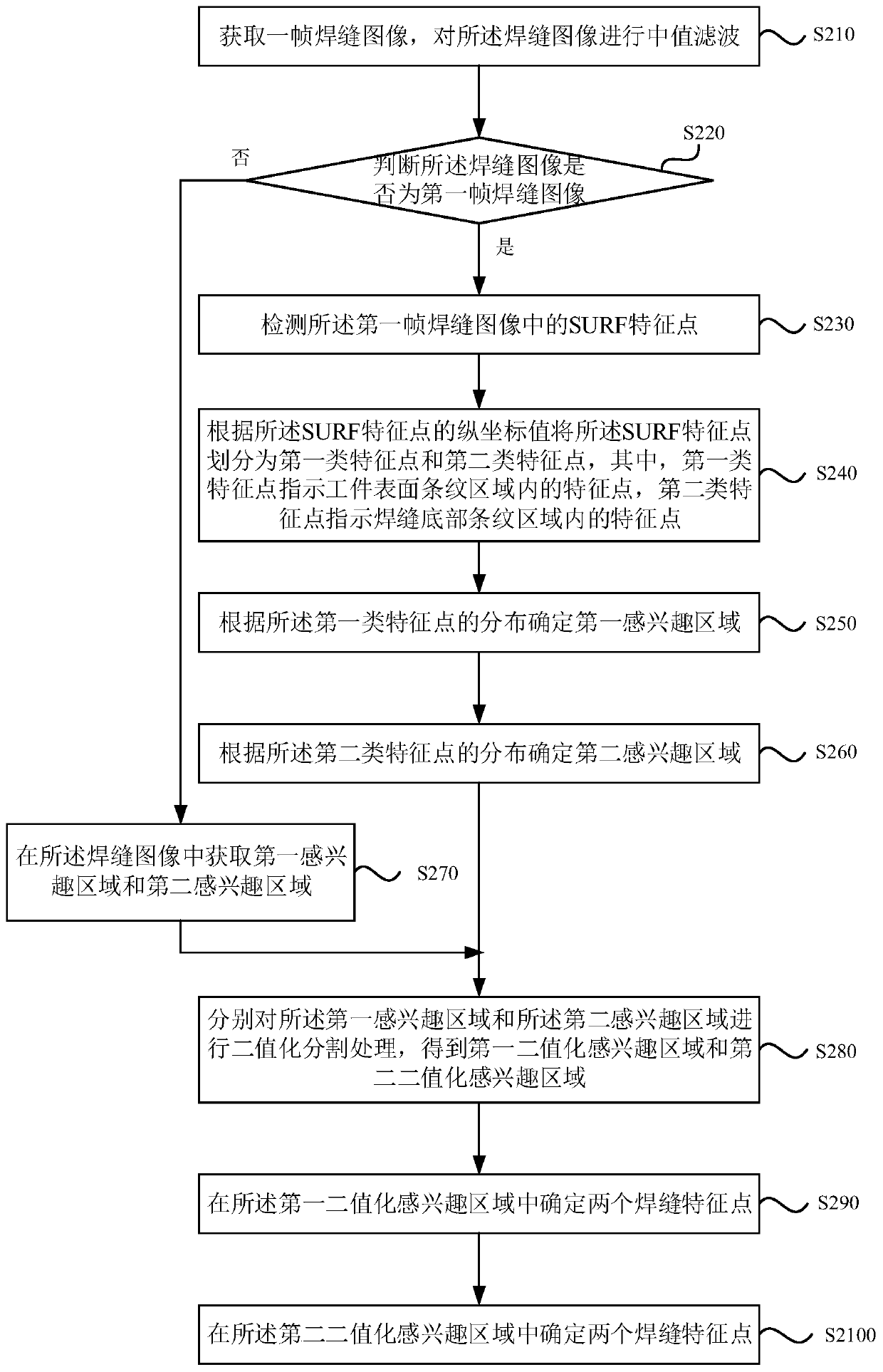

[0052] image 3 It is a flow chart of a method for identifying feature points of butt welds provided by Embodiment 2 of the present invention. On the basis of the above technical solution, this embodiment specifies the division method of the first region of interest and the second region of interest, including: after acquiring the first frame of weld image, detecting the first frame of weld SURF feature points in the image; according to the ordinate value of the SURF feature points, the SURF feature points are divided into a first type of feature point and a second type of feature point, wherein the first type of feature point indicates that within the stripe area of the workpiece surface The feature points of the second type of feature points indicate the feature points in the stripe area at the bottom of the weld; determine the first region of interest according to the distribution of the first type of feature points; determine the second area of interest according to th...

Embodiment 3

[0097] Figure 5 It is a structural schematic diagram of a butt weld feature point identification device provided by Embodiment 3 of the present invention, which is applicable to various interferences such as arc light, spatter, and metal reflection in the welding field application, so that the weld feature point identification is possible In the event of an error, the device can be implemented in the form of software and / or hardware, and generally can be integrated into a weld seam image acquisition device (including a processor).

[0098] Such as Figure 5 As shown, the device for identifying the feature points of the butt weld specifically includes: a region of interest acquisition module 310 , a binarization segmentation processing module 320 and a weld feature point identification module 330 . in,

[0099] A region of interest acquisition module 310, configured to acquire a frame of weld image, and acquire a first region of interest and a second region of interest in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com