Sliding nozzle device

A technology of nozzle device and metal frame, which is applied to casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of recovery, increased workload, danger, etc., and achieves simplified operation, simplified opening and closing operation, and improved operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

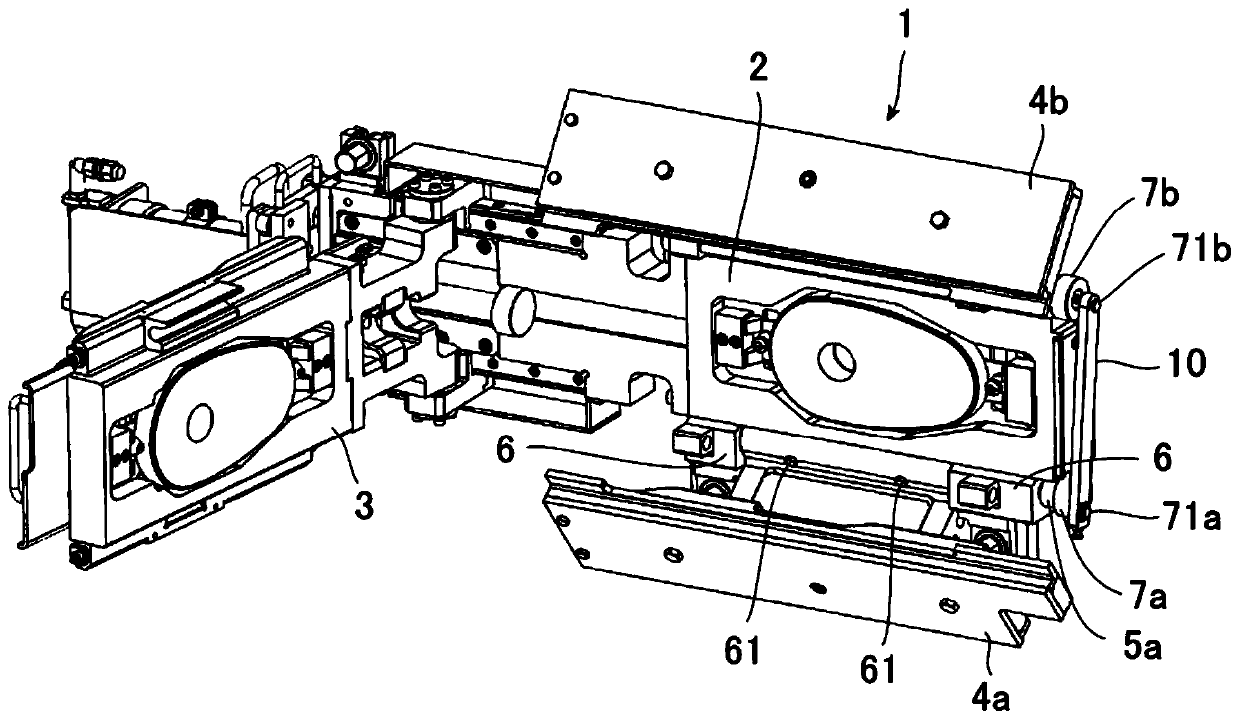

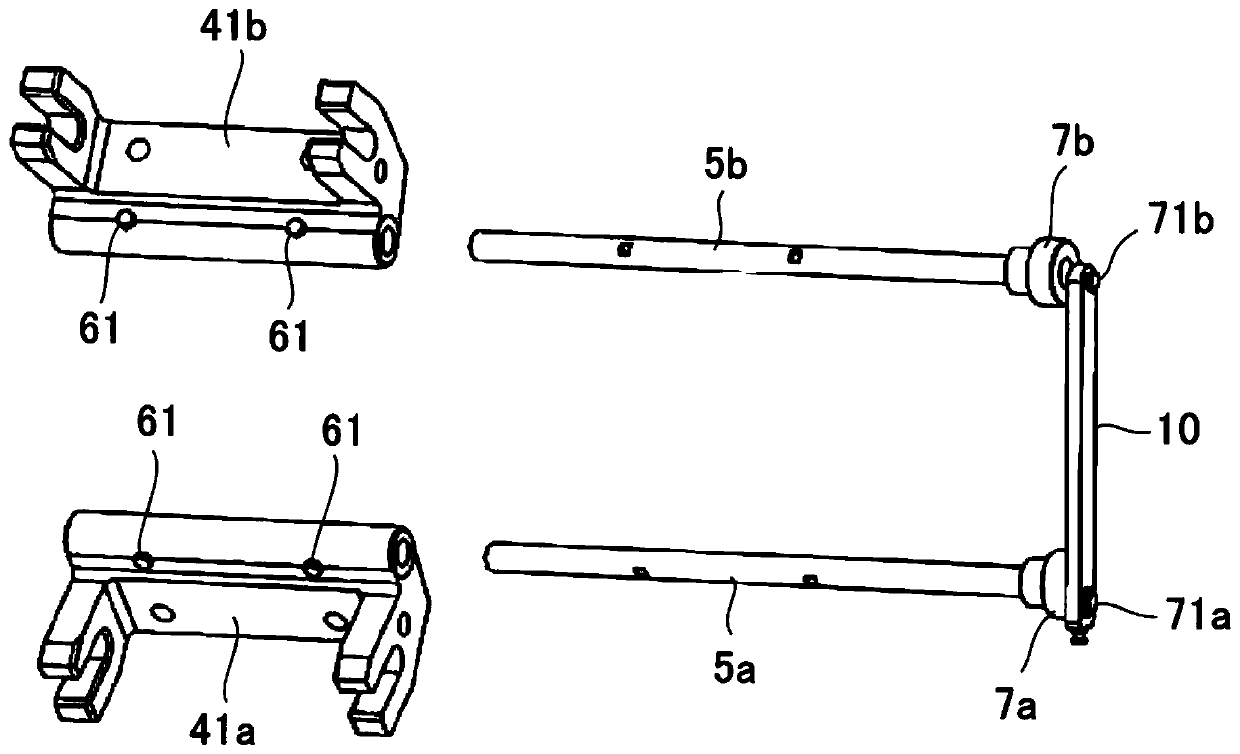

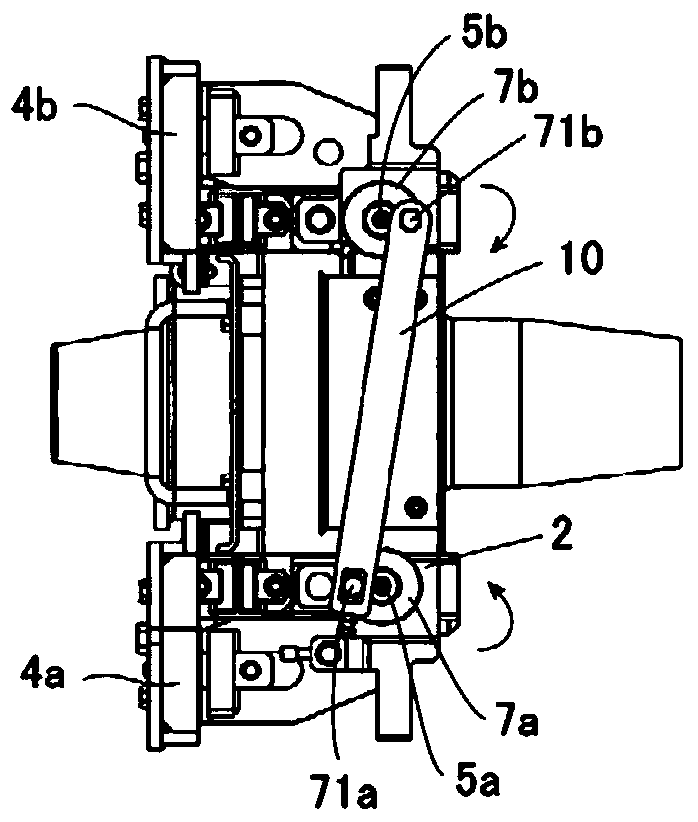

[0042] This embodiment is in patent document 1 namely Figure 8 and Figure 9 An example of applying the present invention based on the sliding nozzle device. Conventionally, the sliding metal frame holder is rotatably held on the pin 22, but in this embodiment, as Figure 1~3 As shown, the pin is integrally formed with the lower sliding metal frame holding portion 4 a as a shaft 5 a, and the shaft 5 a is rotatably held by two shaft holding portions 6 of the fixed metal frame 2 . The shaft 5a is integrally formed with the door-shaped arm 41a of the sliding metal frame holding part 4a via a screw 61, and a first link part 7a is provided at the end of the shaft 5a.

[0043] In addition, a shaft 5b is integrally provided on the upper slide metal frame holding portion 4b, and a second link portion 7b is provided on an end portion of the shaft 5b.

[0044] That is, a disc-shaped first link part 7a and a second link part 7b are respectively attached to the shafts 5a and 5b on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com