Ink-set and printed matter production method

A technology of ink set and printed matter, which is applied in the field of ink set, can solve the problems of not getting high-quality printed matter and fully suppressing bleeding, and achieve the effect of reducing bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0289] Hereinafter, the present invention will be described in further detail through examples.

[0290] (Preparation method of polymer (P-1))

Synthetic example 1

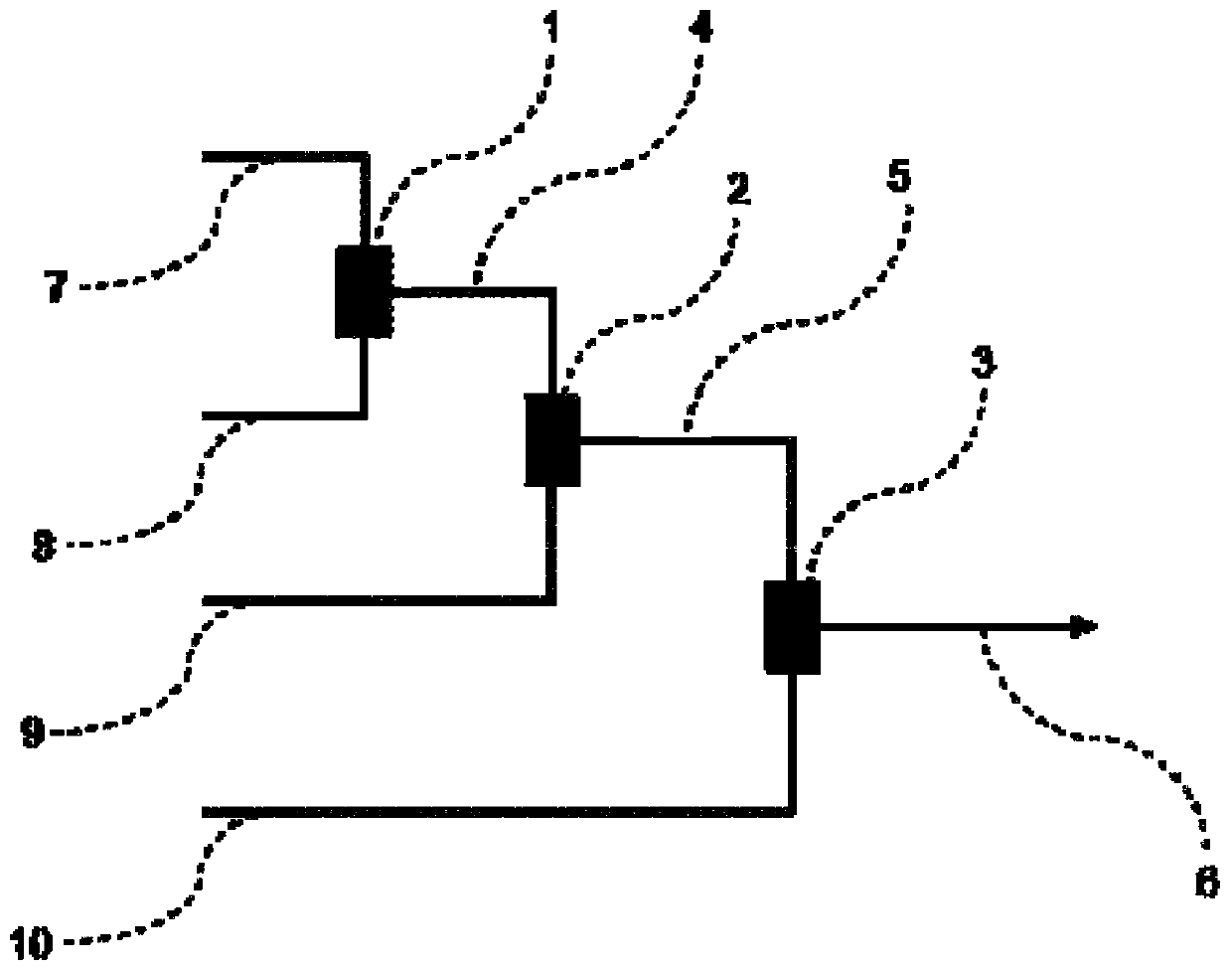

[0292] The hexane solution of BuLi and the styrene solution prepared by dissolving styrene in tetrahydrofuran were prepared from figure 1 The shown tubular reactors P1 and P2 are introduced into a T-shaped micro-mixer M1 to perform living anion polymerization to obtain a polymer.

[0293] Next, pass the polymer obtained in the above process through figure 1 The tubular reactor R1 shown moves to the T-shaped micromixer M2, and the growth terminal of the above-mentioned polymer is captured by the reaction regulator (α-methylstyrene (α-MeSt)) introduced from the tubular reactor P3 .

[0294] Next, a solution of tert-butyl methacrylate obtained by dissolving tert-butyl methacrylate in tetrahydrofuran in advance was figure 1 The shown tubular reactor P4 is introduced into the T-shaped micro-mixer M3 to carry out continuous living anionic polymerization reaction with the above-mentioned captured polymer moving through the tubular reactor R2. Then, the aforementioned living anioni...

manufacture example 1

[0346] (Manufacturing method of production example 1 aqueous pigment dispersion (C-1))

[0347] 150 parts by mass of phthalocyanine-based pigment FASTOGEN BLUE Pigment (manufactured by DIC Co., Ltd.: C.I. Pigment 15:3), 45 parts by mass of polymer (P-1), 150 parts by mass of triethylene glycol, 20 parts by mass of A 34% by mass potassium hydroxide aqueous solution was charged into a 1.0 L intensive mixer (EIRICH Corporation, Japan), and kneaded for 25 minutes at a rotor peripheral speed of 2.94 m / s and a disc peripheral speed of 1 m / s.

[0348] Next, while continuing to stir, 450 parts by mass of ion-exchanged water was slowly added to the kneaded product in the above-mentioned intensive mixer container, and then 185 parts by mass of ion-exchanged water was further added and mixed to obtain an aqueous solution with a pigment concentration of 15% by mass. Pigment Dispersion (C-1).

[0349] (Manufacturing methods of production examples 2 to 4 aqueous pigment dispersions)

[03...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap