Nose bridge strip supply device of full-automatic mask machine

A supply device, fully automatic technology, applied in clothing, application, transportation and packaging, etc., can solve problems such as instability, inconvenient debugging and maintenance, complex dynamic structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

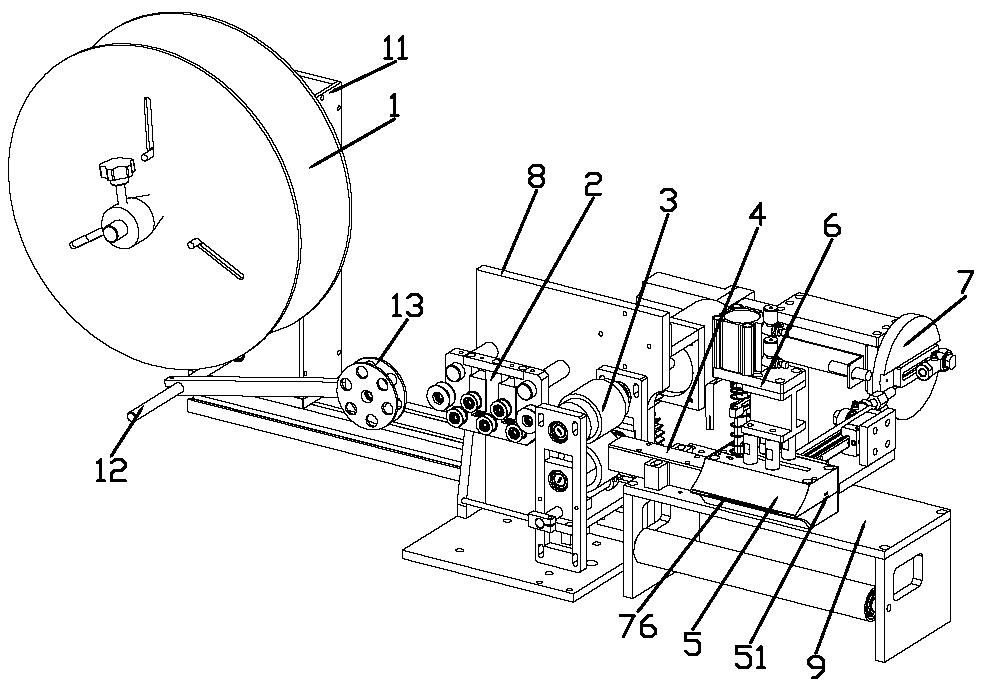

[0023] Such as figure 1 with figure 2 As shown, a full-automatic mask machine nose strip supply device includes a feeding tray 1, and the feeding tray 1 is installed on the side of the installation box 11, and the lower end of the installation box 11 is also provided with a fixed rod 12, and the end of the fixed rod 12 The guide wheel 13 is connected by a connecting arm connected by rotation.

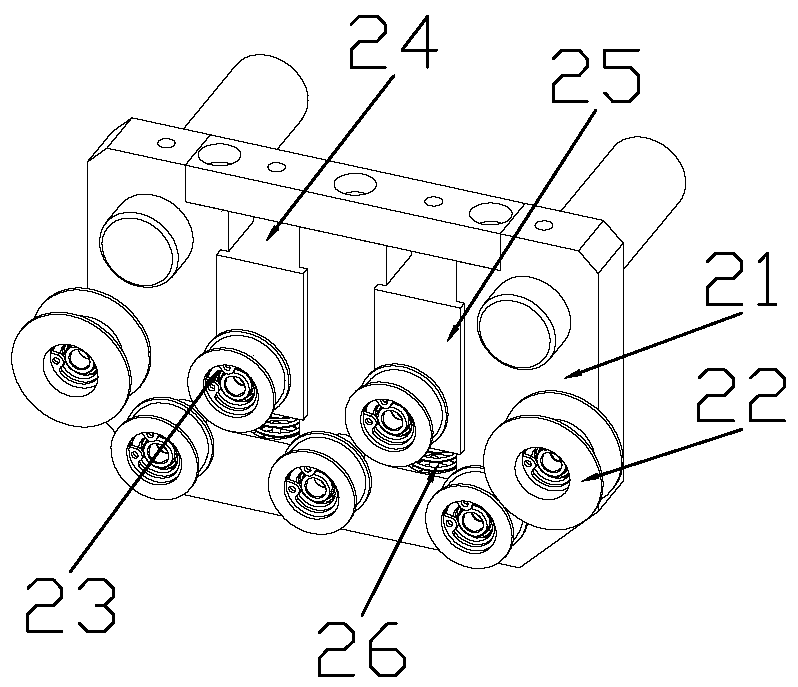

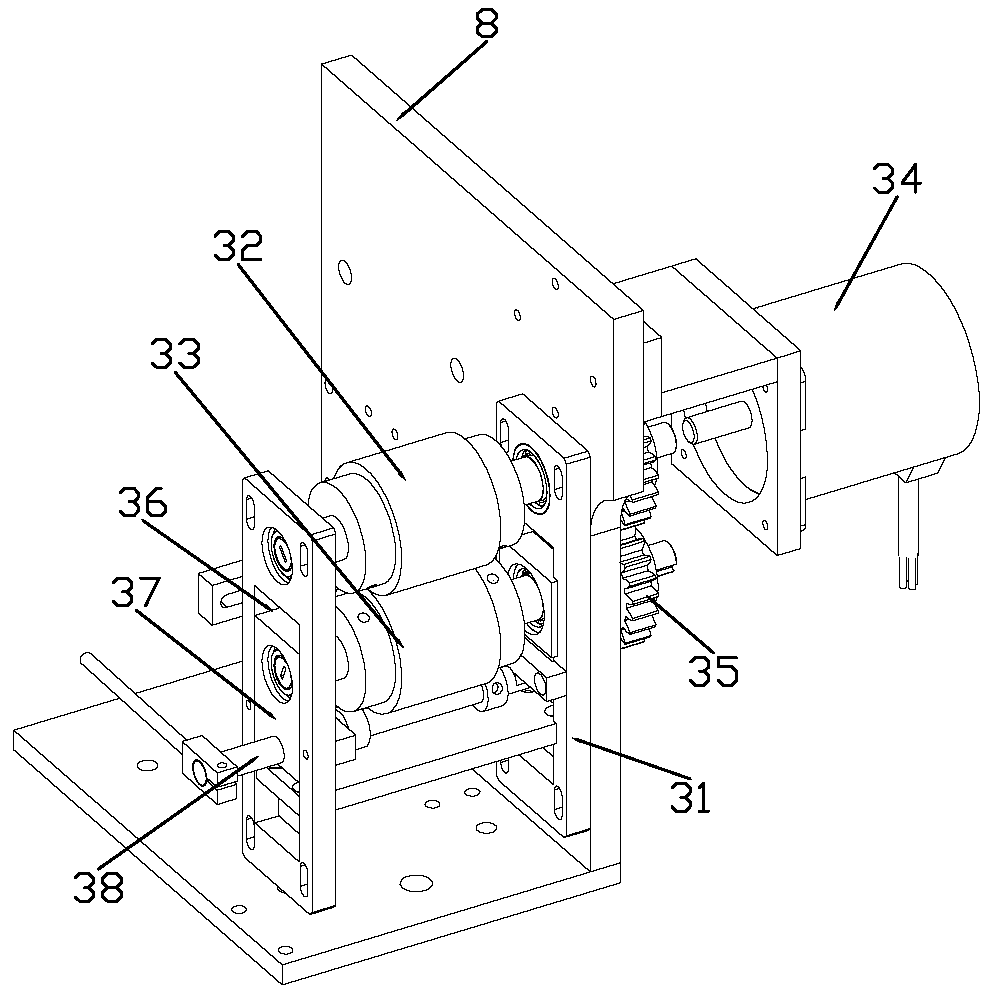

[0024] The discharge end of the feeding tray 1 is provided with a shaping mechanism 2, and the shaping mechanism 2 is installed on the first fixing plate 21, and the first fixing plate 21 is connected to one side of the mounting plate 8 through a connecting column. The shaping mechanism 2 includes The first shaping wheels 22 arranged along the length direction of the first fixing plate 21 are interlaced with the second shaping wheels 23 which are movably connected with the mounting plate 8 . Specifically, the height of the first shaping wheels 22 located at both ends is higher than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com