High-precision straightening machine for steel pipe machining

A high-precision, straightening machine technology, applied in the field of steel pipe straightening, can solve the problems that affect the accuracy of steel pipe straightening, the inability to dissipate heat from the straightening wheel, and the deformation of the straightening wheel, so as to improve precision, ensure service life, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

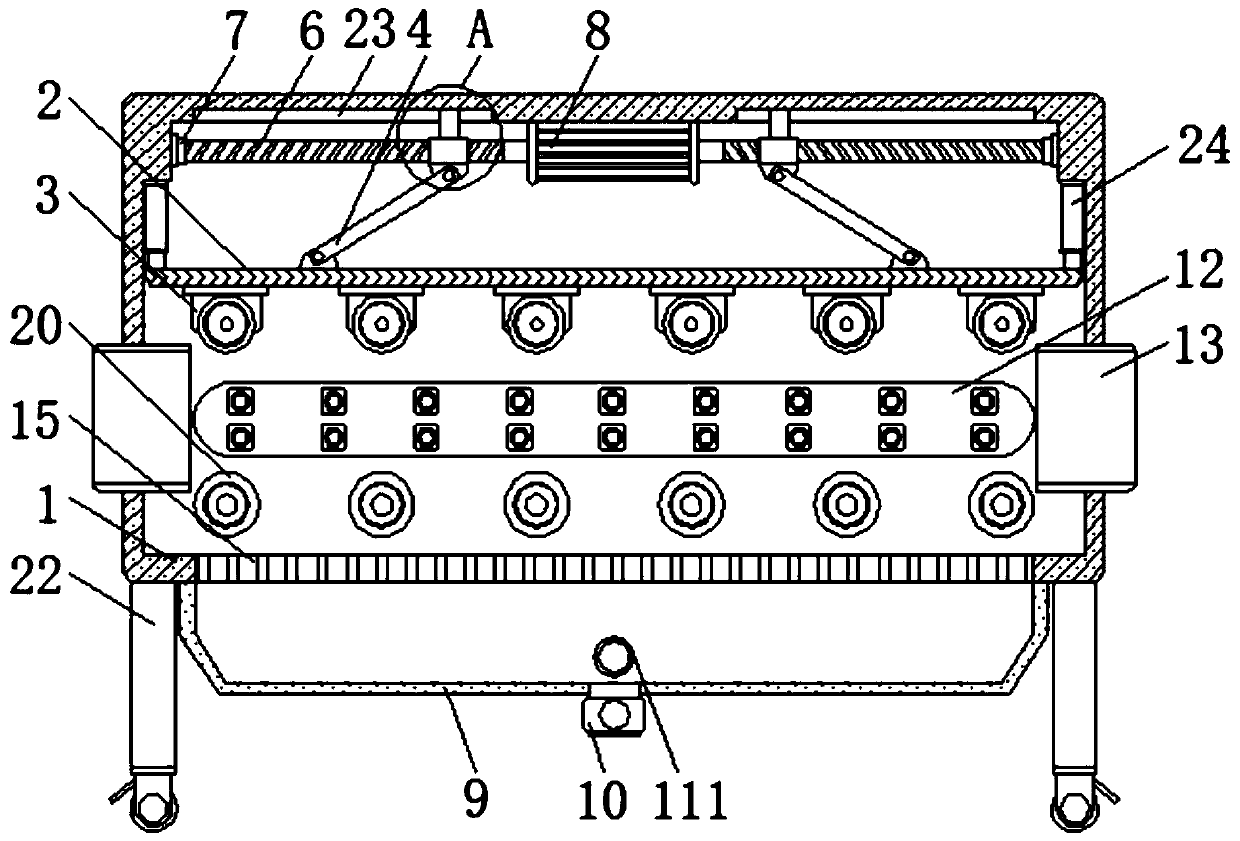

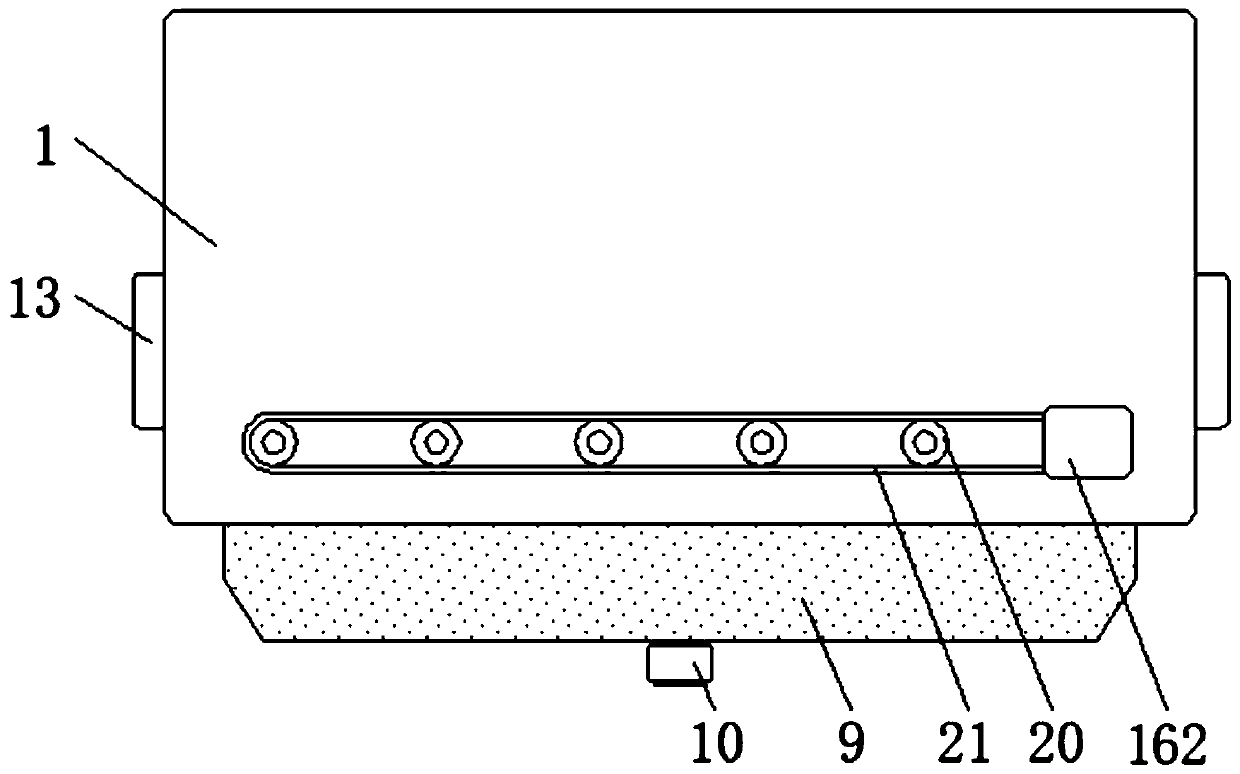

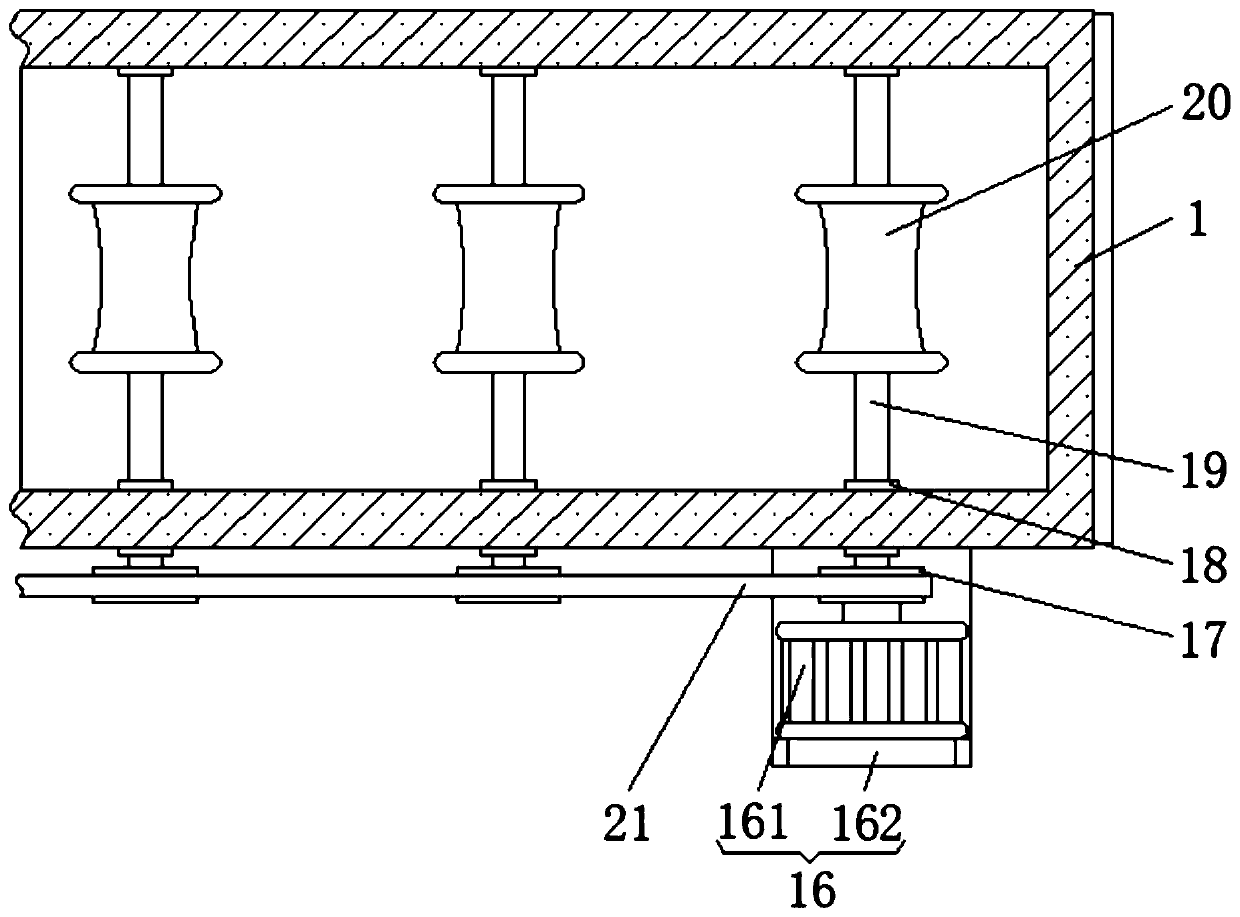

[0027] like Figure 1-5 As shown, the present invention provides a technical solution: a high-precision straightening machine for steel pipe processing, comprising a casing 1, a supporting plate 2 is arranged in the casing 1, and the lower surface of the supporting plate 2 is provided with several straightening Wheel 3, the upper surface of the support plate 2 is movably connected with the bottom ends of the two connecting rods 4 through two pin shafts, respectively, and the top end of the connecting rod 4 is movably connected with the lower surface of the threaded cap 5 through the pin shaft, and the threaded cap 5 is connected with the lower surface of the threaded cap 5. The mutual cooperation between the threaded rods 6 makes the threaded rod 6 more stable when the threaded cap 5 moves during the rotation process. The threaded cap 5 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com