Automotive suspension system with tilting resistance and cross-country performance

A technology of automobile suspension and wheels, applied in the direction of suspension, interconnection system, vehicle components, etc., to achieve the effect of good balance and good off-road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

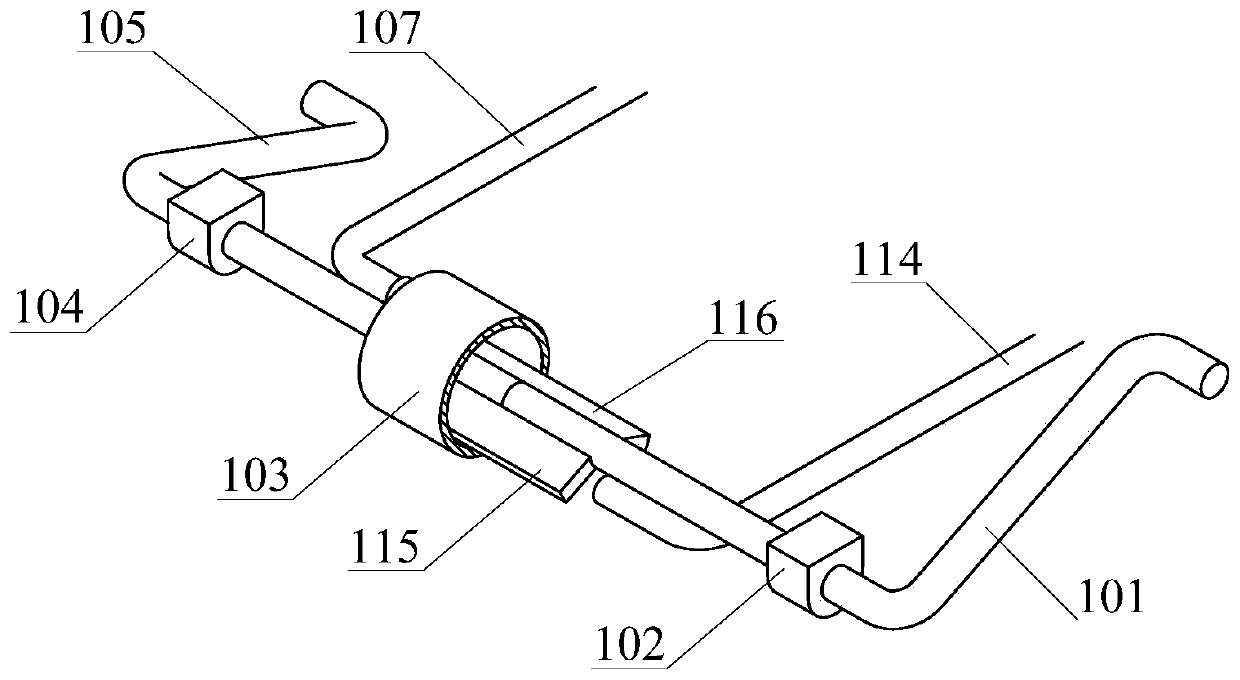

[0029] Below with the accompanying drawings Figure 1 to Figure 8 Describe in detail.

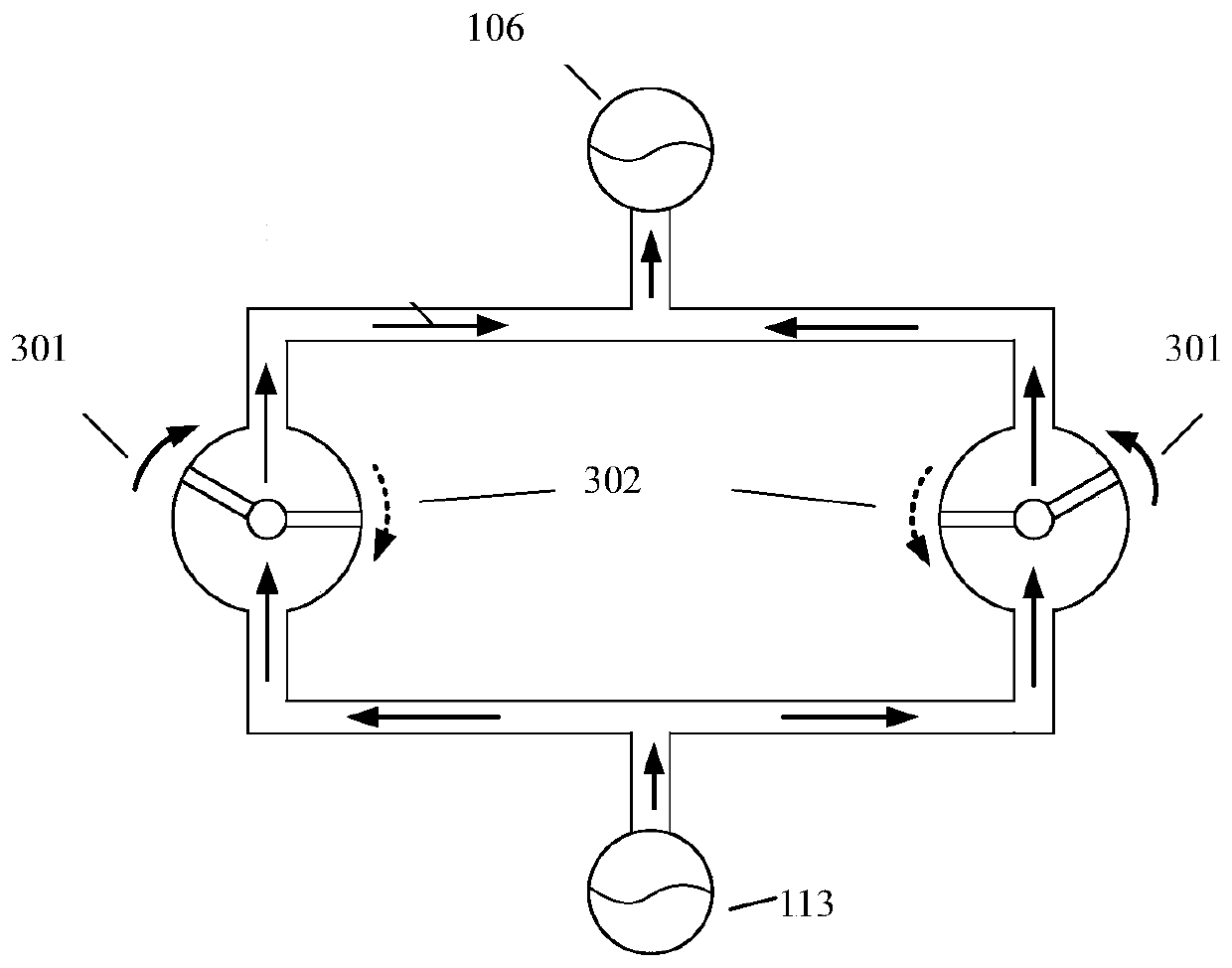

[0030] The automobile suspension system with anti-rolling and off-road performance of the present invention can also be called a dynamically adjusted automobile suspension system, a stable automobile suspension, a dynamically adjusted hydraulic circuit system, and the like.

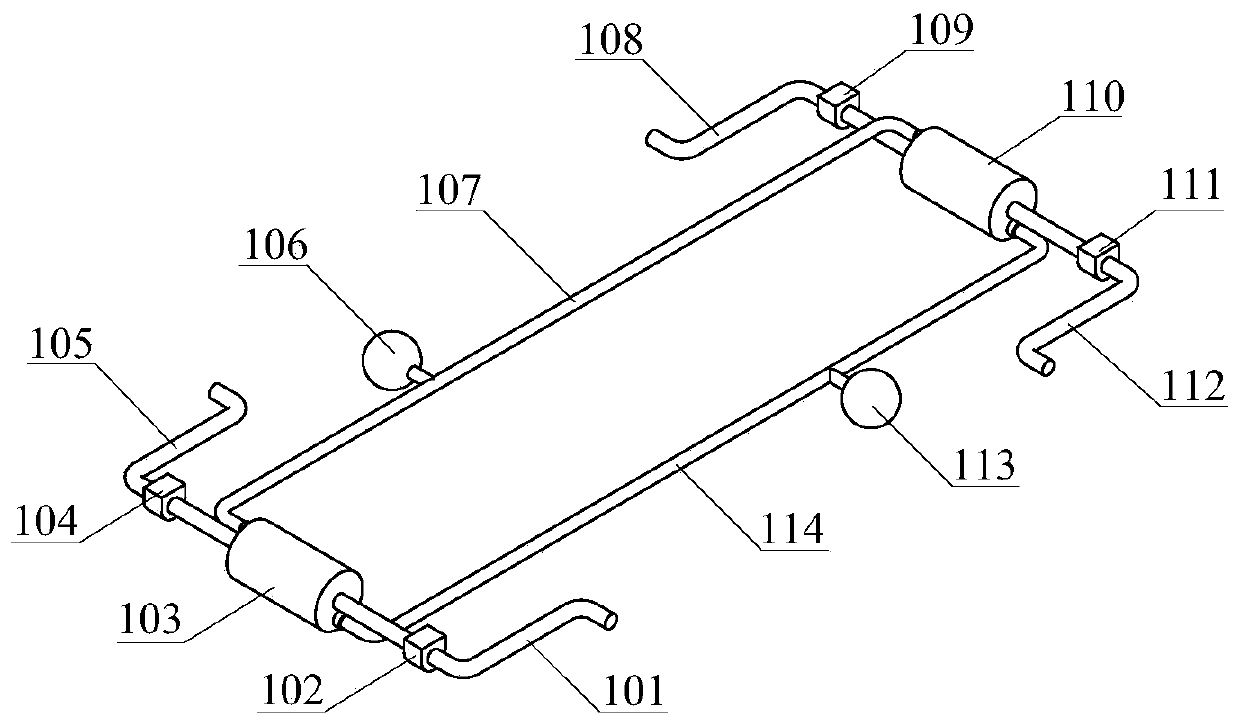

[0031] Such as figure 1 As shown, the automobile suspension system with both anti-rolling and off-road performances of the present invention includes a first stabilizing unit and a second stabilizing unit, and the first stabilizing unit and the second stabilizing unit pass through an oil pipe and at least one accumulator Hydraulic adjustment unit connection. The first stabilizing unit and the second stabilizing unit do not contain electronic control devices. The first stabilizing unit is arranged between the front wheels of the vehicle, and the second stabilizing unit is arranged between the rear wheels of the vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com