Automobile chassis structure

A technology of automobile chassis and frame, which is applied in the direction of substructure, vehicle parts, transportation and packaging, etc. It can solve the problems of increasing development cost, prolonging the development cycle, and difficult maintenance, so as to ensure the balance of force and expand the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

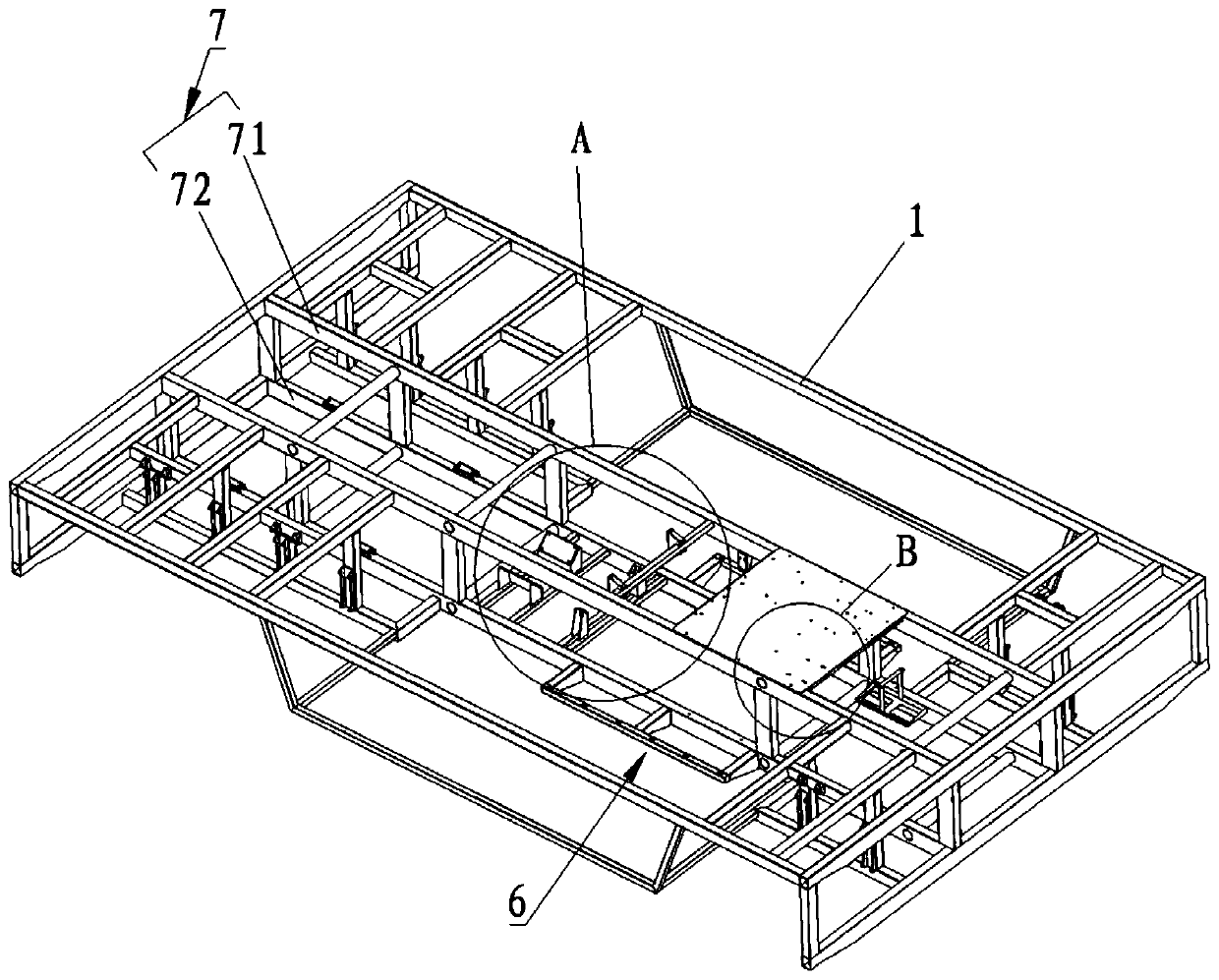

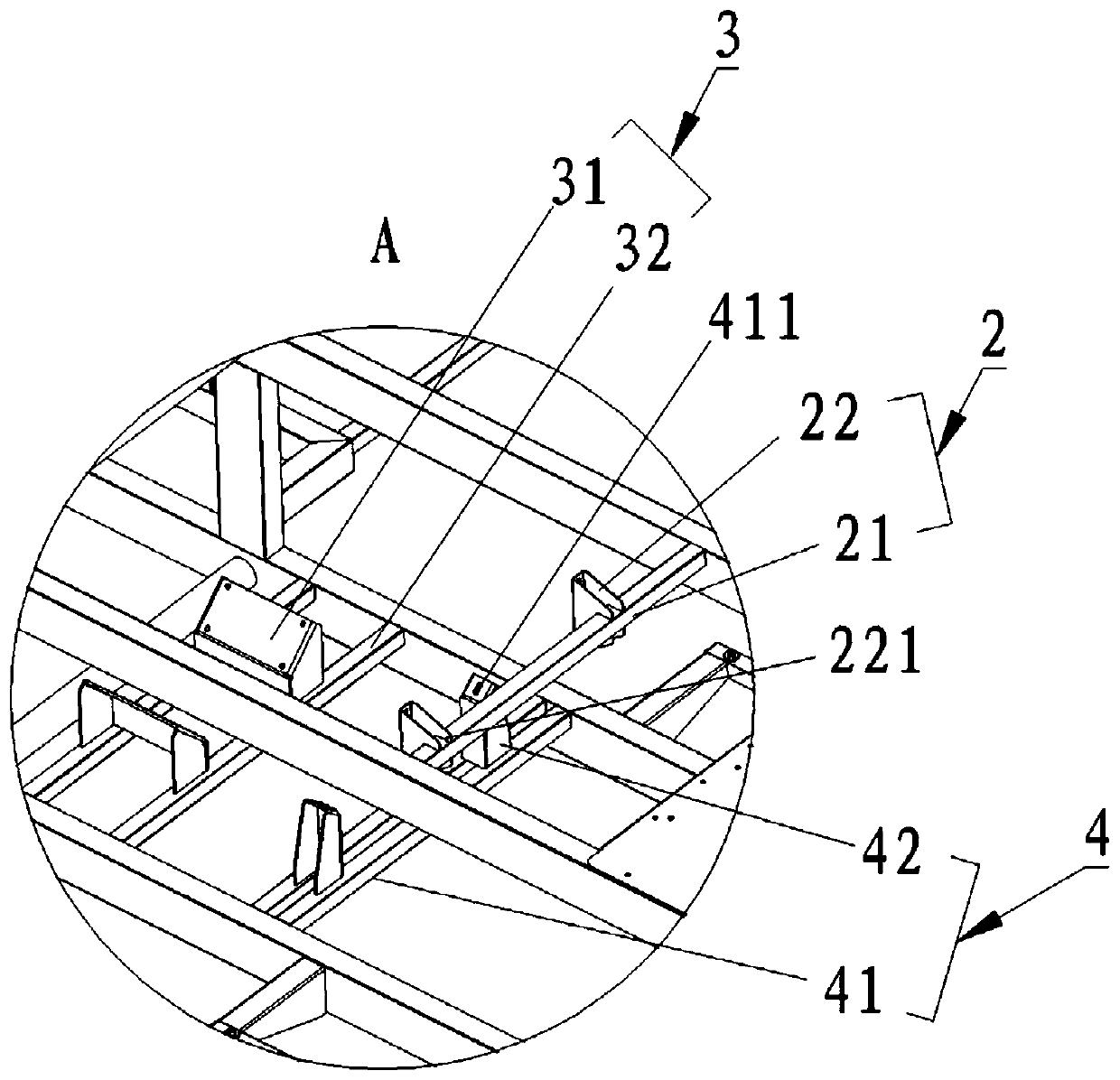

[0066] Please refer to Figure 1-Figure 6 , an automobile chassis structure, comprising a vehicle frame 1, a water tank mounting frame 2, a first driving mechanism mounting frame 3, a second driving mechanism mounting frame 4, a control mechanism mounting frame 5 and a plurality of power supply mechanism mounting frames 6;

[0067] The frame 1 is divided into a first area 11, a second area 12 and a third area 13 by a plurality of longitudinal rod groups 7;

[0068] The first area 11 and the third area 13 are symmetrically distributed;

[0069] The first driving mechanism mounting frame 3 and the second driving mechanism mounting frame 4 are sequentially installed in the lower side of the second area 12;

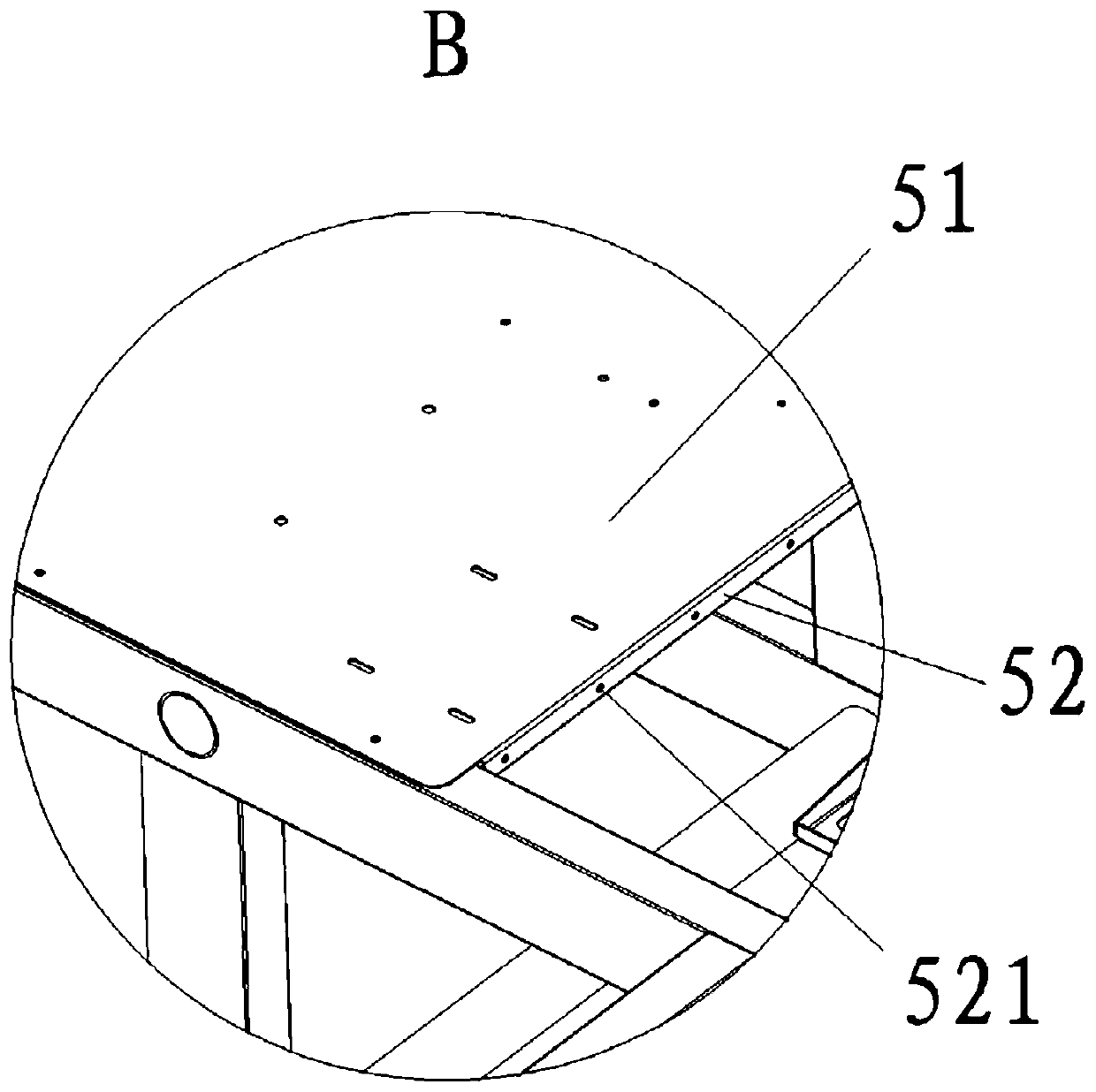

[0070] The control mechanism mounting frame 5 and the water tank mounting frame 2 are sequentially installed in the upper side of the second area 12;

[0071] The power supply mechanism installation frame 6 is installed in the lower side of the first area 11 .

[0072] Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com