Hoisting device and hoisting method applied to high-altitude hoisting of umbrella-shaped column light component

A light-weight component and hoisting device technology, applied in building components, special structures, walking mechanisms, etc., can solve the problems of limited construction operation space, high cost of construction equipment, poor mobility and other problems, achieve fast production, improve construction efficiency, strong The effect of adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

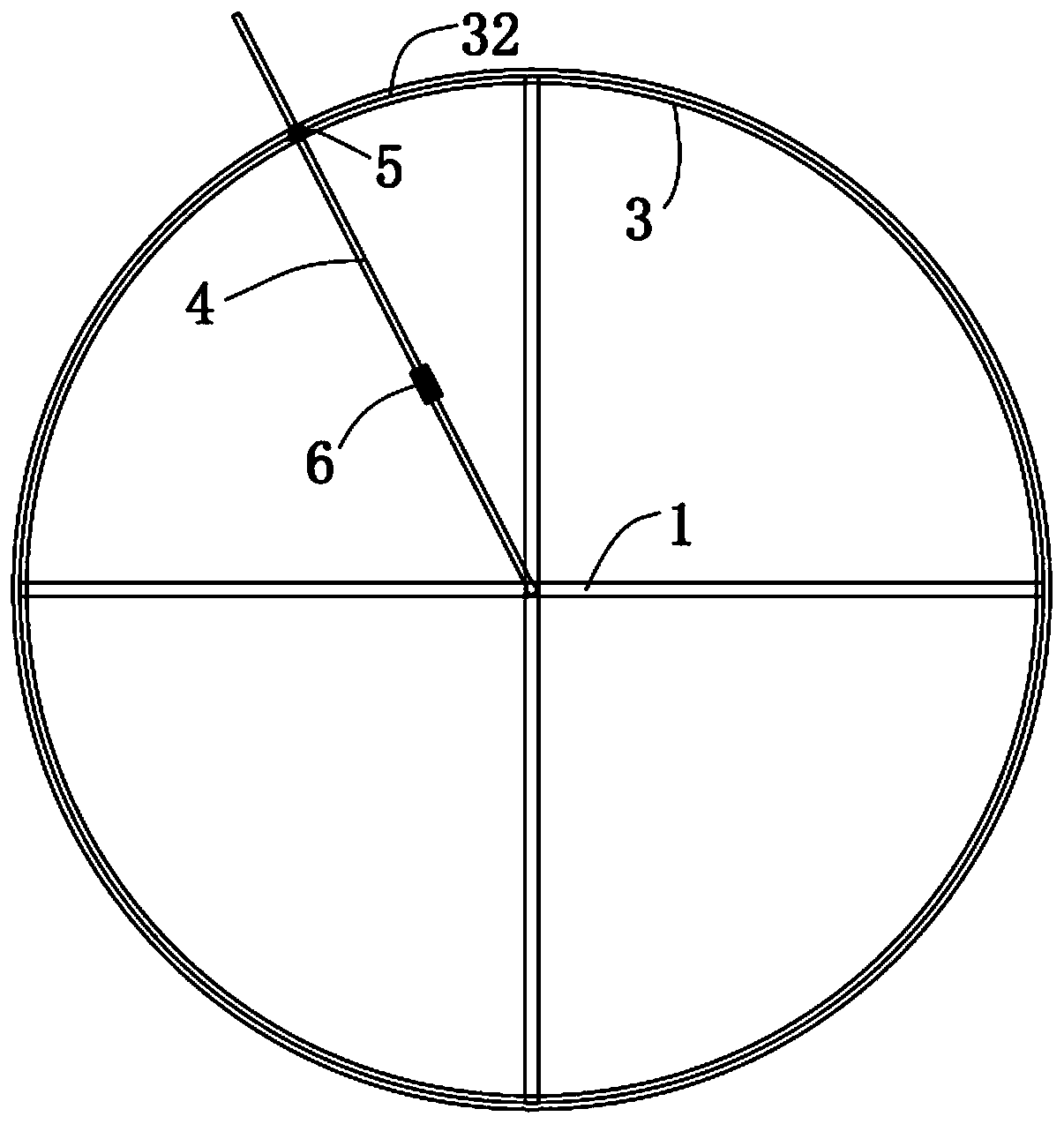

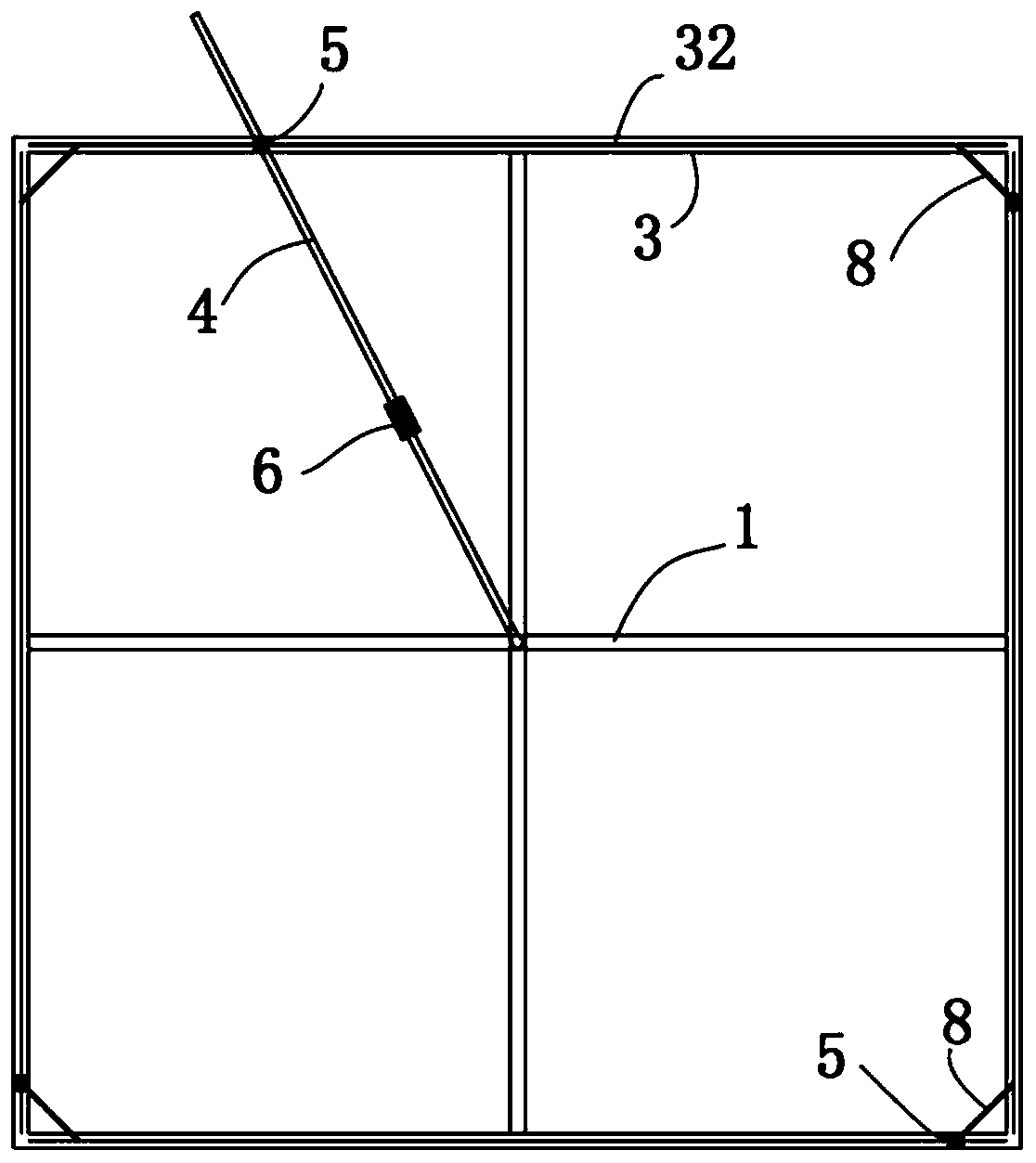

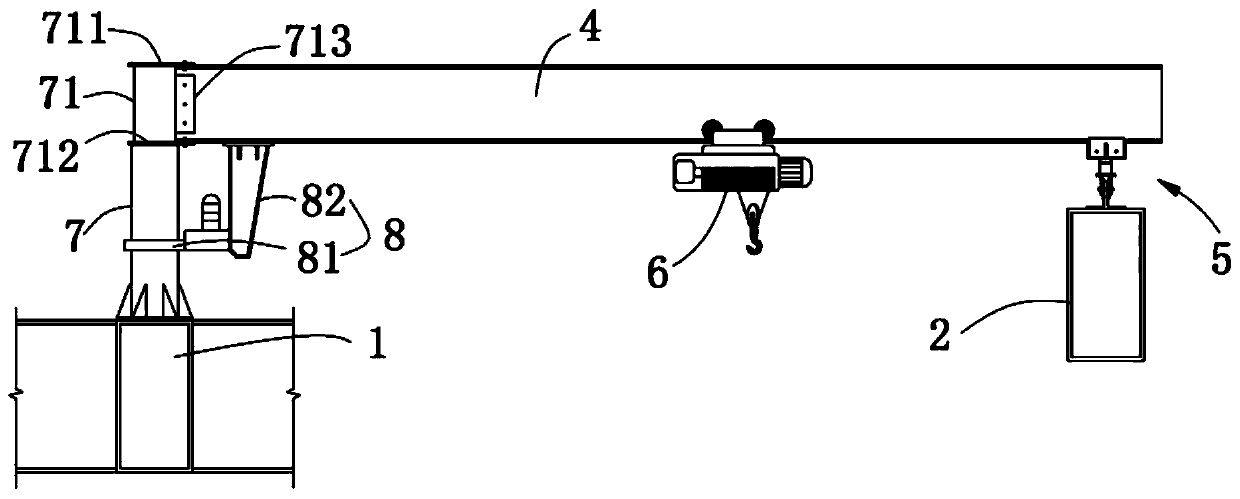

[0044] see Figure 1 to Figure 3 , the present invention provides a hoisting device applied to the high-altitude hoisting of umbrella-shaped light-weight components. Column edge beam 2; described hoisting device comprises track 3, crane beam 4, slide assembly 5 and hoisting part 6, carries out the hoisting of the required light member of umbrella-shaped column construction by above-mentioned device being installed on the top of umbrella-shaped column, so The range of motion of the hoisting device is small, and it is not easy to collide with other structures during the hoisting of light components. Compared with the hoisting equipment in the prior art, the application uses the crane beam 4, the track 3, the sliding assembly 5 and the lifting parts The hoisting system composed of 6 has simple structure, conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com