Concrete pouring conveyor in narrow and small roof sealing space at high altitude and construction method

A conveying device and concrete technology, which is applied in construction, building structure, and construction material processing, etc., can solve the problems of high potential safety hazards, difficult control of delivery volume, and high construction cost, and achieve low safety hazard risks and easy delivery volume Simple effect of control and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

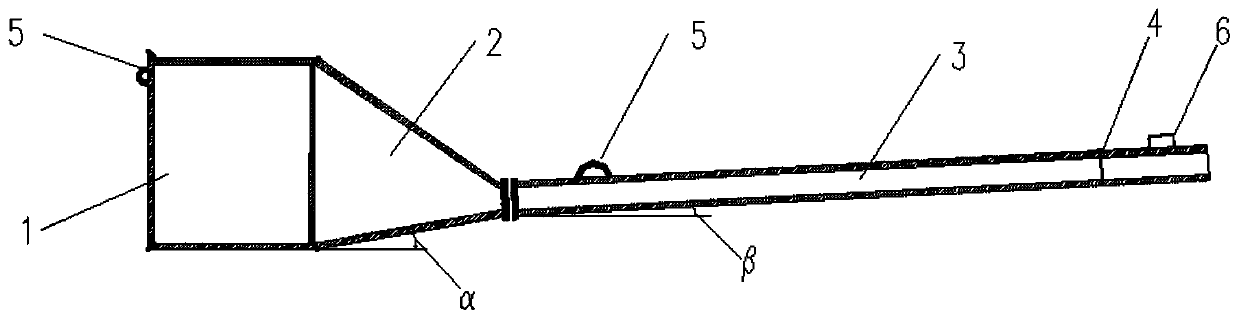

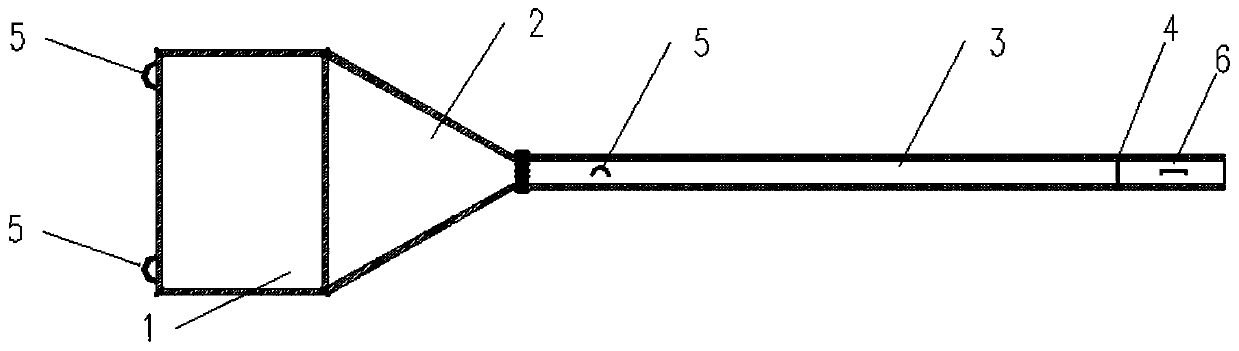

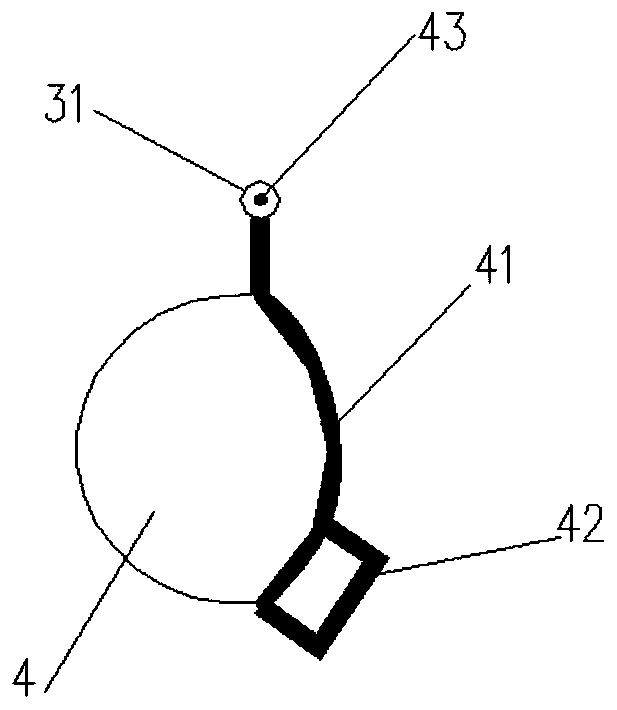

[0025] Such as figure 1 with figure 2 As shown, the concrete pouring and conveying device in the high-altitude narrow capped space provided by the embodiment of the present invention is mainly composed of a cube tank 1 with a top and a side opening, a funnel-shaped container 2 and a long hollow tube 3, wherein one end of the funnel-shaped container 2 is Circular opening, the other end is a square opening, one end of the square opening of the funnel-type container 2 is connected with the side of the opening of the cube groove 1, and one end of the round opening of the funnel-type container 2 is connected with the hollow long tube 3 one end, and the hollow long tube 3 is provided near the free end position. There is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com