Sectional material connecting structure and shower room

A technology for connecting structures and shower rooms, which is applied in the direction of building types, building structures, special buildings, etc., can solve the problems of adjustable frame or fixed frame damage, easily damaged frame surface, inconvenient installation, etc., and achieve the effect of improving the overall appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

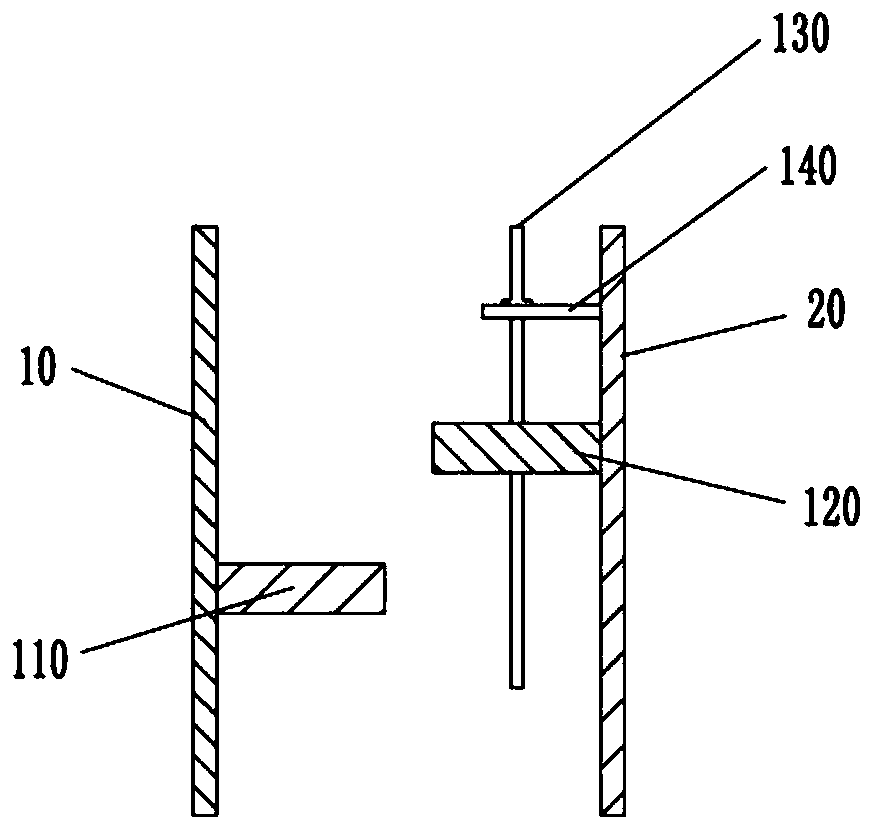

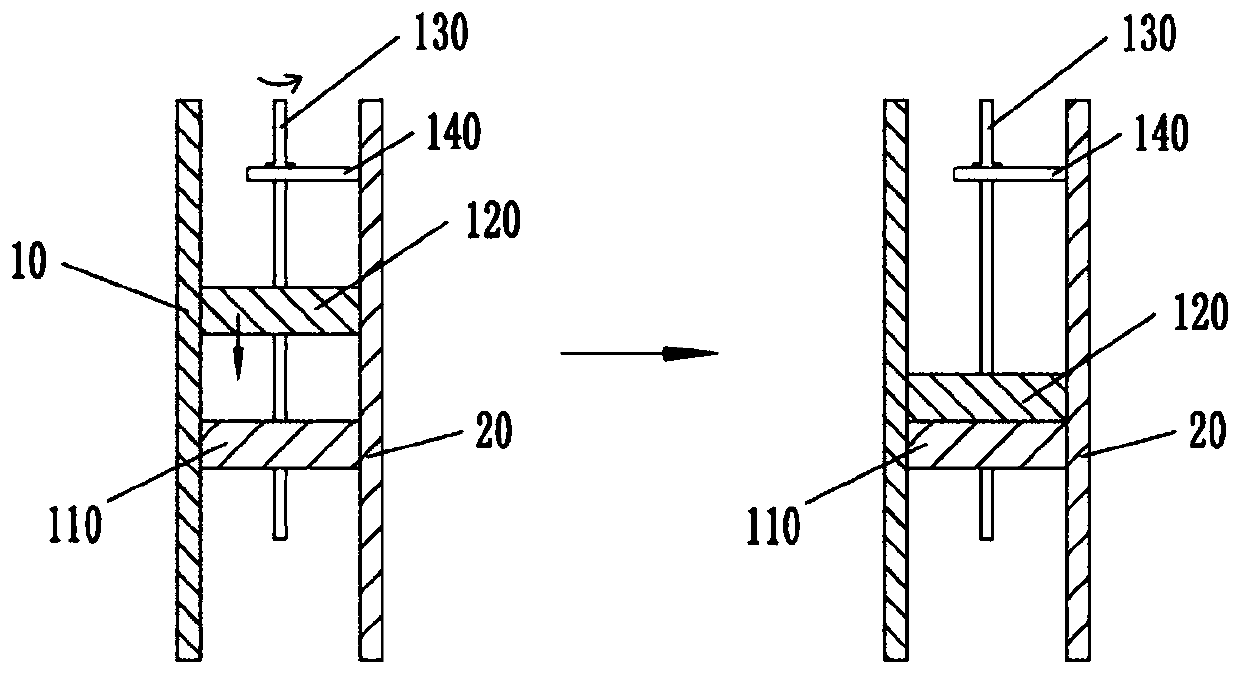

[0074] refer to Figure 1-2 , which shows a profile connection structure, including: a first limiting member 110 , a second limiting member 120 , an operating member 130 and a first supporting member 140 .

[0075] The first limiting member 110 is fixed to the first profile 10 . In each embodiment of the present invention, threaded fasteners are used to fasten the first limiting member 110 to the first profile 10 , of course, other fastening methods may also be used.

[0076] The second limiting member 120 is configured to be slidably connected to the second profile 20 only along the length direction. In other words, relative to the second profile 20 , the second limiting member 120 only has the degree of freedom to slide along the lengthwise direction, is connected to the second profile 20 in a fixed rotation, and cannot move relative to the second profile 20 in the first direction. Each embodiment of the present invention preferably realizes the above-mentioned configurati...

Embodiment 2

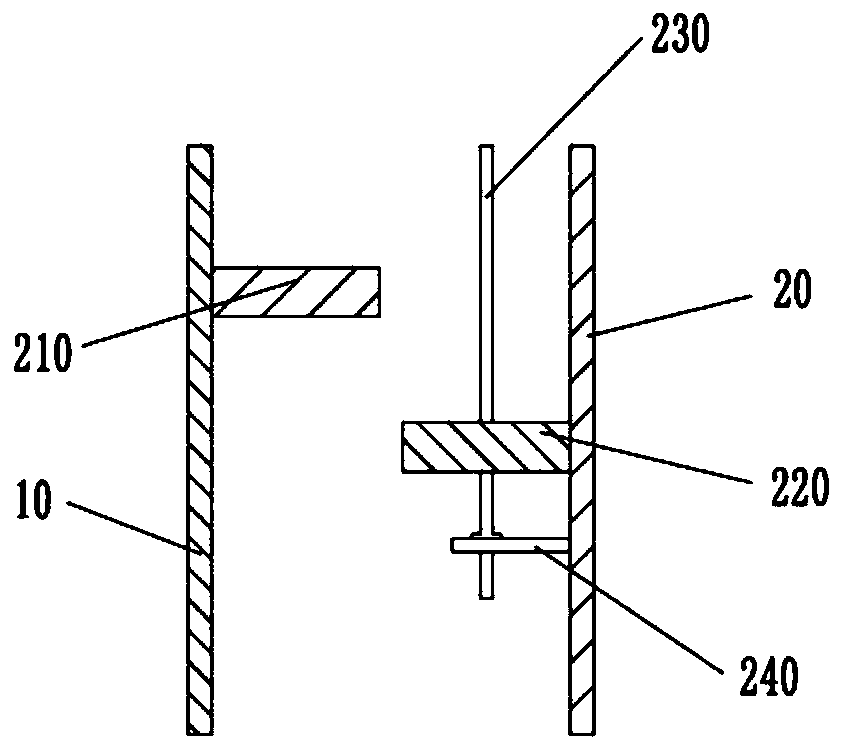

[0087] refer to Figure 3-4 , which shows another profile connection structure different from that of Embodiment 1, which includes: a first limiting member 210 , a second limiting member 220 , an operating member 230 and a second supporting member 240 .

[0088] The first limiting member 210 is fixed to the first profile 10 .

[0089] The second limiting member 220 is configured to be slidably connected to the second profile 20 only along the length direction, and is limited by the first limiting member 210 in the first direction when it slides to a locked position.

[0090] The operating member 230 is rotatably connected to the second profile 20 , and drives the second limiting member 220 to slide to the locking position through screw fit. Since the operating member 230 is screwed with the second limiting member 220 , when the operating member 230 is not driving the second limiting member 220 , the two are relatively fixed in the length direction and form a whole.

[0091] ...

Embodiment 3

[0100] This embodiment provides a more specific and preferred embodiment of applying the present invention to the shower room scene. refer to Figure 5-20 , Embodiment 3 provides a profile connection structure, which includes a first limiter 310, a second limiter 320, a first sliding fit seat 350, a third limiter 330, a fourth limiter 340, a Two sliding fit seats 360 and an operating part 370 .

[0101] It is worth noting that, as can be seen from the drawings, the first profile 10 and the second profile 20 corresponding to this embodiment are inserted and fitted along the first direction to form a plug-fit perpendicular to the second direction. In order to realize the limited cooperation between the two in the second direction through its own structure. Moreover, since this embodiment is applied to a shower room scene, the first profile 10 and the second profile 20 are both arranged vertically.

[0102] Returning to the connection structure of this embodiment, the first li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com