A shock-absorbing sealing pipe joint

A technology for sealing pipes and casings, applied in the directions of pipes/pipe joints/fittings, pipe elements, adjustable connections, etc., which can solve the problems of inability to guarantee shock absorption and weakening, improve the stable conveying effect and reduce the turbulent phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

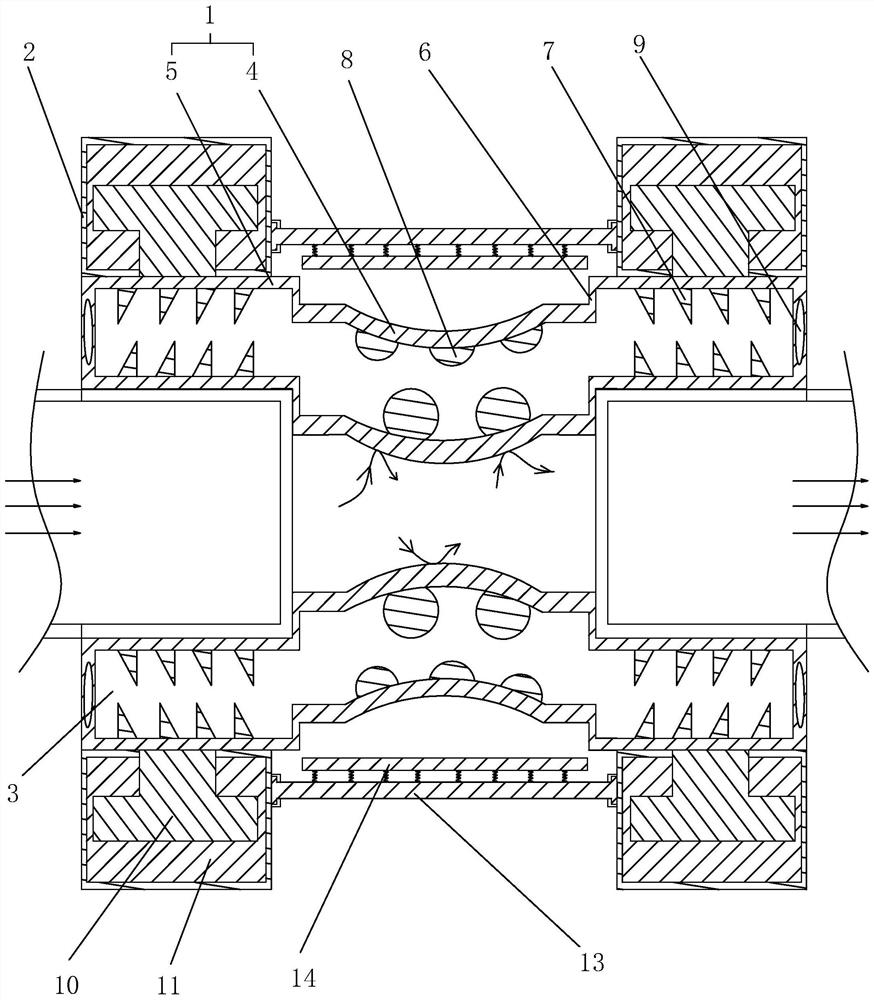

[0022] Embodiment: a kind of shock-absorbing sealed pipe joint, such as figure 1 As shown, it includes the flexible pipe body 1 and the sleeves 2 sleeved at both ends of the flexible pipe body 1. In the actual installation process, the operator only needs to set the flexible pipe body 1 on the ports of the two pipes to be connected. And it can be fixed through the casing 2 .

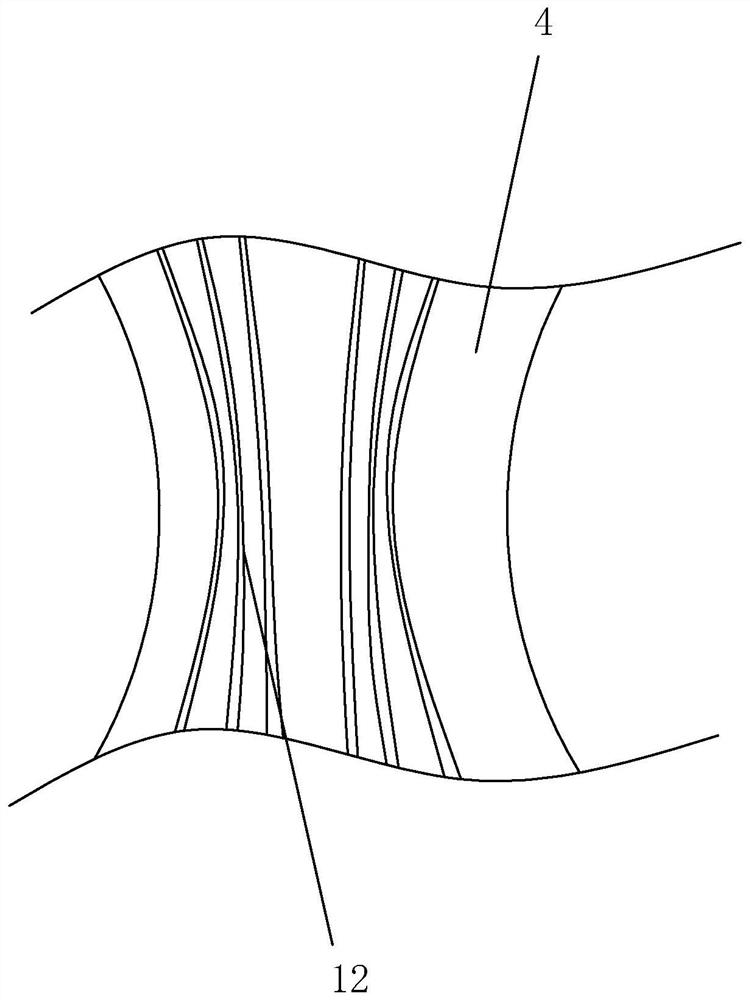

[0023] Since the circulating medium in the pipeline will produce a lot of fluctuations and shocks when passing through the pipeline connector, the flexible conduit in the pipeline connector includes a shock-absorbing tube 4 and fixed tubes 5 arranged at both ends of the shock-absorbing tube 4. The nozzle is socketed, and the shock-absorbing tube 4 in the middle of the flexible conduit can realize the buffering and shock-absorbing effect.

[0024] An elastic cavity 3 is provided in the tube wall of the flexible pipe body 1, wherein a shock absorber assembly is arranged in the elastic cavity 3 in the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com