Co-simulation method and device for battery modules

A battery module and co-simulation technology, applied in the field of simulation, can solve the problems of affecting the simulation accuracy, the calculation of heat dissipation is not accurate enough, and the temperature distribution of the battery pack cannot be reflected, so as to achieve the effect of improving the simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

[0026] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

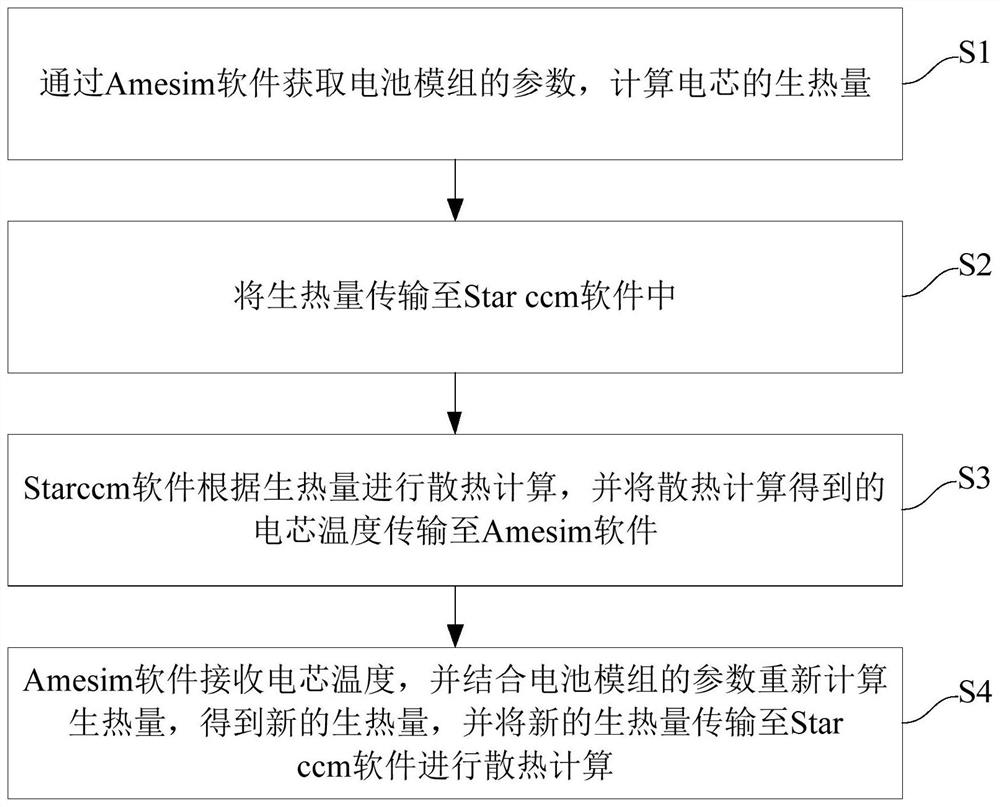

[0027] figure 1 It is a flowchart of a co-simulation method for a battery module according to an embodiment of the present invention. like figure 1 As shown, the co-simulation method for a battery module according to an embodiment of the present invention includes the following steps:

[0028] Step S1: Obtain the parameters of the battery module through Amesim software, and calculate the heat generation of the battery cells.

[0029] Specifically, the parameters of the battery module are obtained through the Amesim software, and the heat generation of the battery cells is calculated, which specifically includes: calling a pre-stored battery heat genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com