Six-phase rectification generator winding coil inserting structure and coil inserting method

A rectifier generator, wire structure technology, applied in the shape/style/structure of winding insulation, the shape/style/structure of winding conductor, and the manufacture of motor generators, etc. Problems such as raised ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: A six-phase rectifier generator winding embedded wire structure

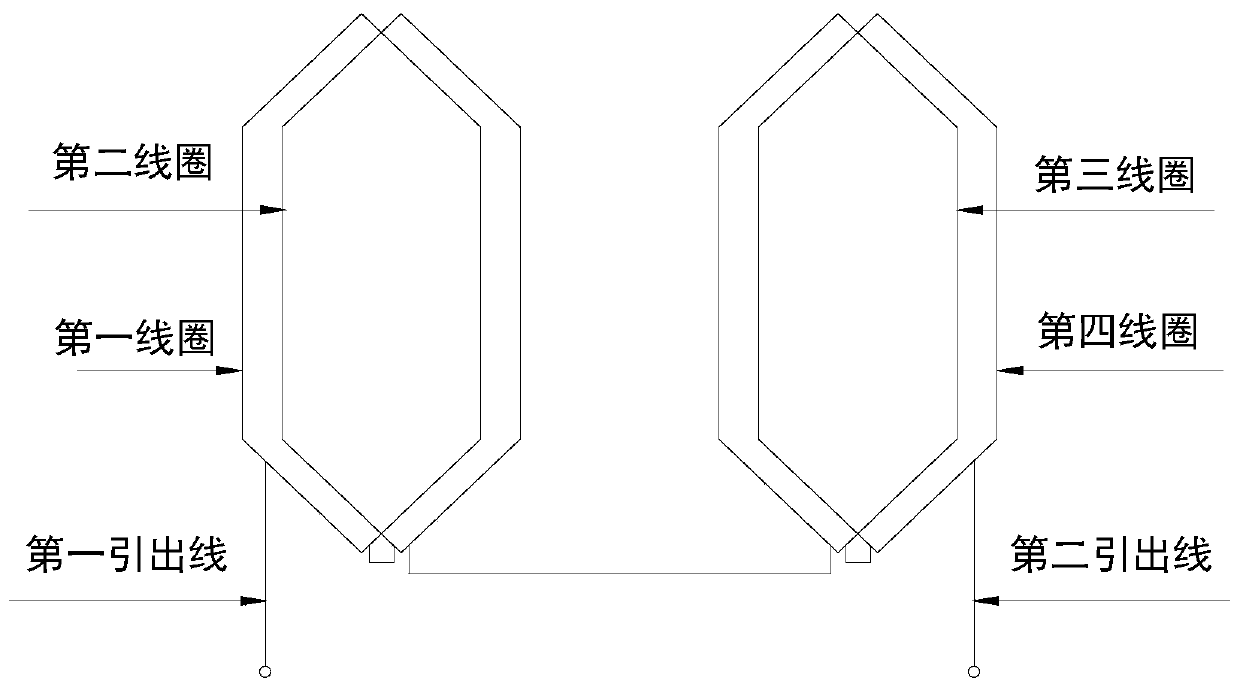

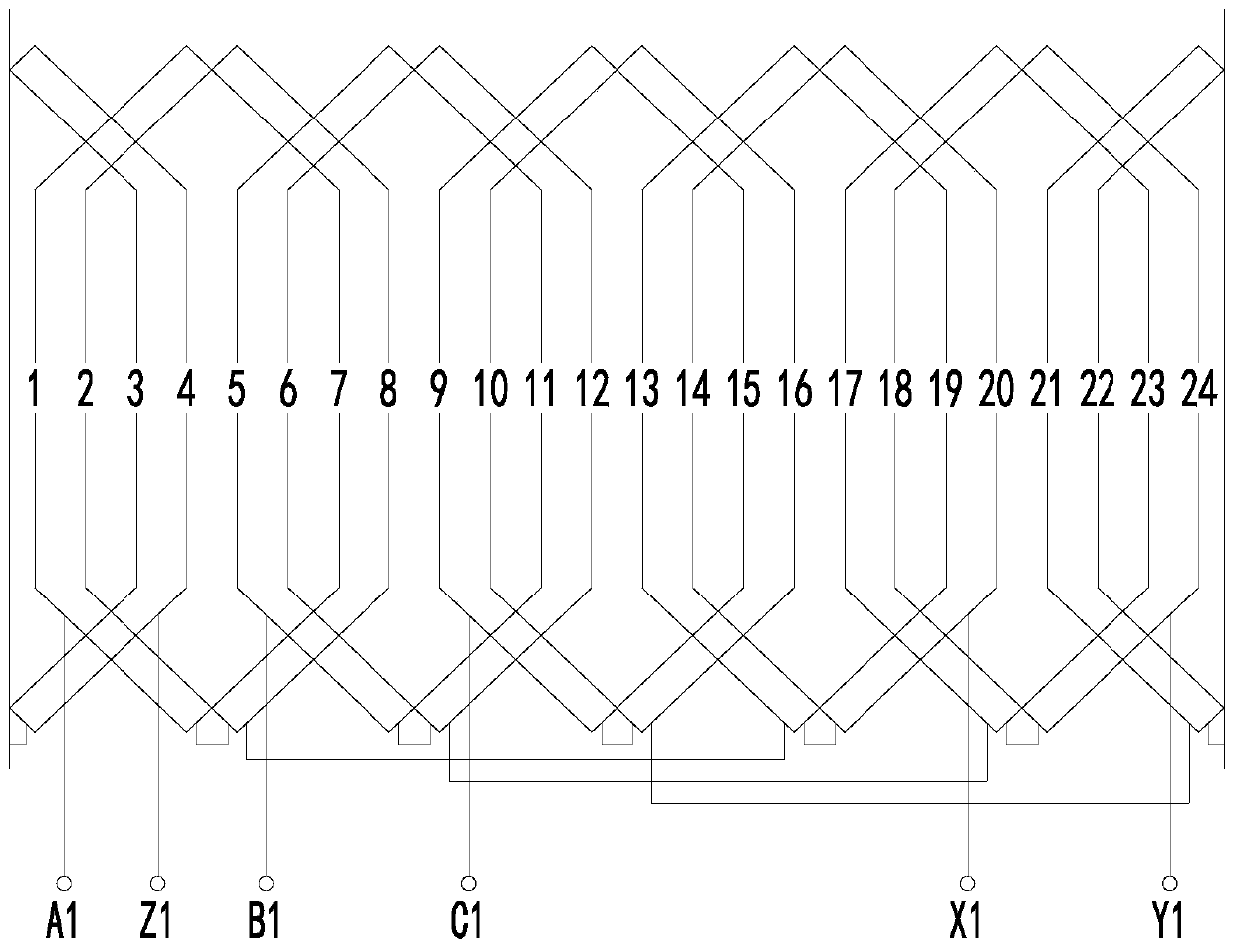

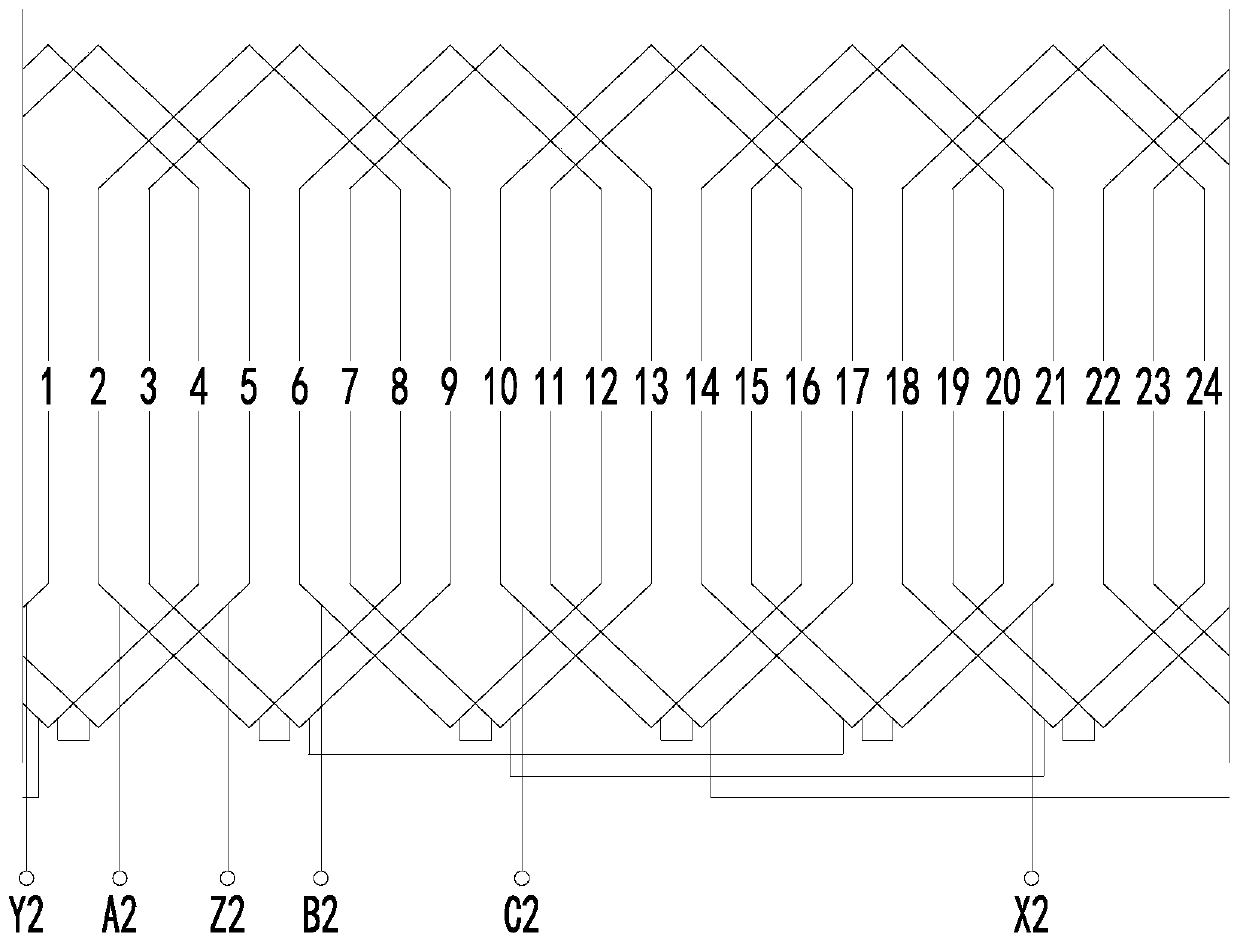

[0035] like Figure 1-3 As shown, an embodiment 1 of the present invention discloses a six-phase rectifier generator winding embedded wire structure including a stator iron core, the stator iron core is provided with a first three-phase winding and a second three-phase winding, and the first three-phase winding includes A1 Phase, B1 phase, C1 phase, the second three-phase winding includes A2 phase, B2 phase, C2 phase, the number of magnetic poles of the stator is 4; the first three-phase winding and the second three-phase winding The phase windings and the second three-phase windings are both distributed full-pitch single-layered windings; each of the first three-phase windings and the second three-phase windings includes a first coil, a second coil, and a third coil connected in series in sequence and the fourth coil; the pitches of the first coil, the second coil, the third coil and the f...

Embodiment 2

[0045] Embodiment 2: A six-phase rectifier generator winding embedding method

[0046] Embodiment 2 of the present invention also discloses a wire embedding method based on the six-phase rectifier generator winding wire embedding structure described in Embodiment 1, comprising the following steps:

[0047] Step 1: Send the first coil of the A1 phase and the first side of the second coil in the first three-phase winding into the No. 1 wire slot and No. 2 wire slot respectively, and at the same time put the A1 phase in the first three-phase winding. The edges of the first coil and the second coil of the second coil are lifted, leaving the No. 7 wire slot and No. 8 wire groove;

[0048] Step 2: Send the first coil of phase B1 and the first edge of the second coil in the first three-phase winding into the No. 5 wire slot and No. 6 wire slot respectively, and at the same time send the B1 phase of the first three-phase winding. The first coil and the second coil of the second coil ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap