Lead wire structure of a claw-pole miniature permanent magnet synchronous motor coil

A permanent magnet synchronous motor and claw-pole technology, applied in structural connections, electrical components, electromechanical devices, etc., can solve problems such as unfavorable transformation and upgrading, waste of raw materials, slow production efficiency, etc., to improve production efficiency, reduce production costs, Reduce the effect of lead-out lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

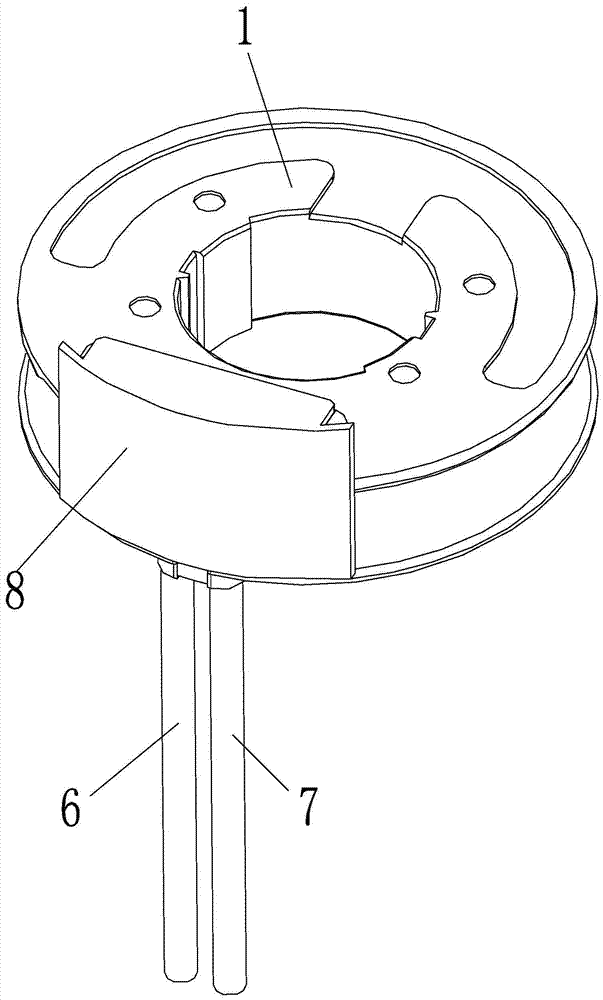

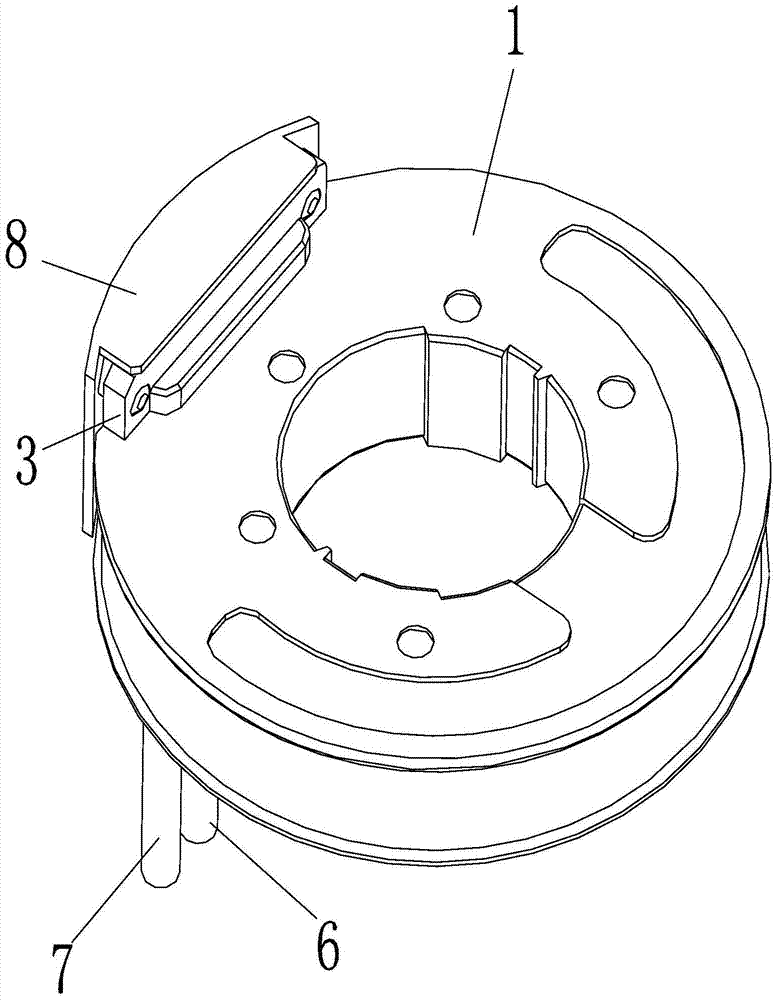

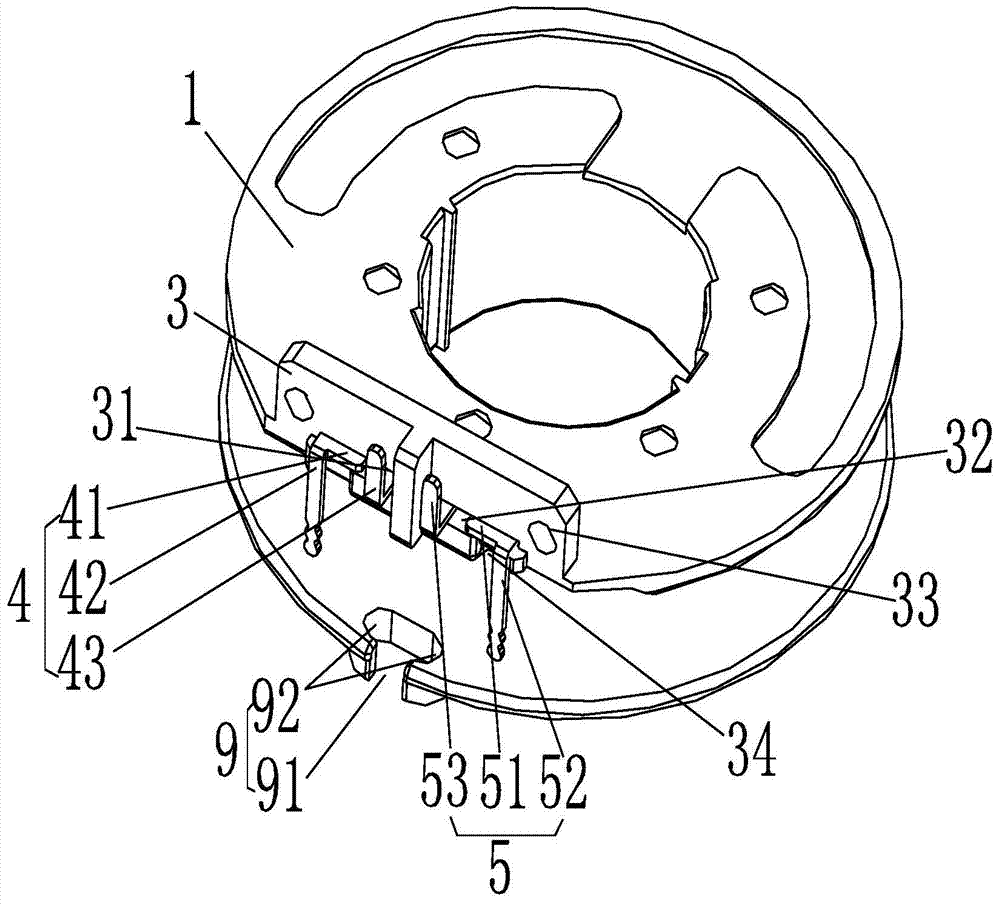

[0032] like Figure 1-6 As shown, the lead wire structure of a claw-pole miniature permanent magnet synchronous motor coil provided by the present invention includes a bobbin 1 wound with a coil 2 and a boss provided on the bobbin 1 for wiring 3; also includes the first connection terminal 4, the second connection terminal 5, the first wire 6, the second wire 7 and the protective cover 8;

[0033] The boss 3 is provided with a first mounting groove 31 and a second mounting groove 32;

[0034] The first connecting terminal 4 includes a first conductive installation piece 41 arranged horizontally, one end of the first installation piece 41 extends downwards in the vertical direction and a first electrode 42 is provided, and the other end of the first installation piece 41 extends vertically downwards. There is a first conductive connecting piece 43 extending vertically upward; the first mounting piece 41 is clamped in the first mounting groove 31;

[0035] The second connectin...

Embodiment 2

[0043] This embodiment is characterized in that: the first wire is fixedly connected to the first conductive connection piece by welding; the second wire is fixedly connected to the second conductive connection piece by welding. Others are the same as in Example 1.

Embodiment 3

[0045] The feature of this embodiment is that: the boss is provided with two clamping posts, and correspondingly, the protective cover is provided with two clamping holes; the two clamping posts of the boss are respectively inserted into the In the two clamping holes of the protective cover, a snap connection is realized between the protective cover and the boss. Others are the same as in Example 1.

[0046] Other examples:

[0047] The insulating partition is arranged on the protective cover, or the insulating partition is arranged on the boss. The protective cover is provided with openings for leading out the first wire and the second wire, or the winding frame is provided with openings for leading out the first wire and the second wire, or the An opening for leading out the first wire and the second wire is jointly formed between the protective cover and the winding frame.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap