Brake device for a working machine

A technology of braking equipment and operating machinery, which is applied in the direction of brakes, braking transmission devices, braking action starting devices, etc., can solve the problems of increasing safety risks and achieve the effect of improving braking behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

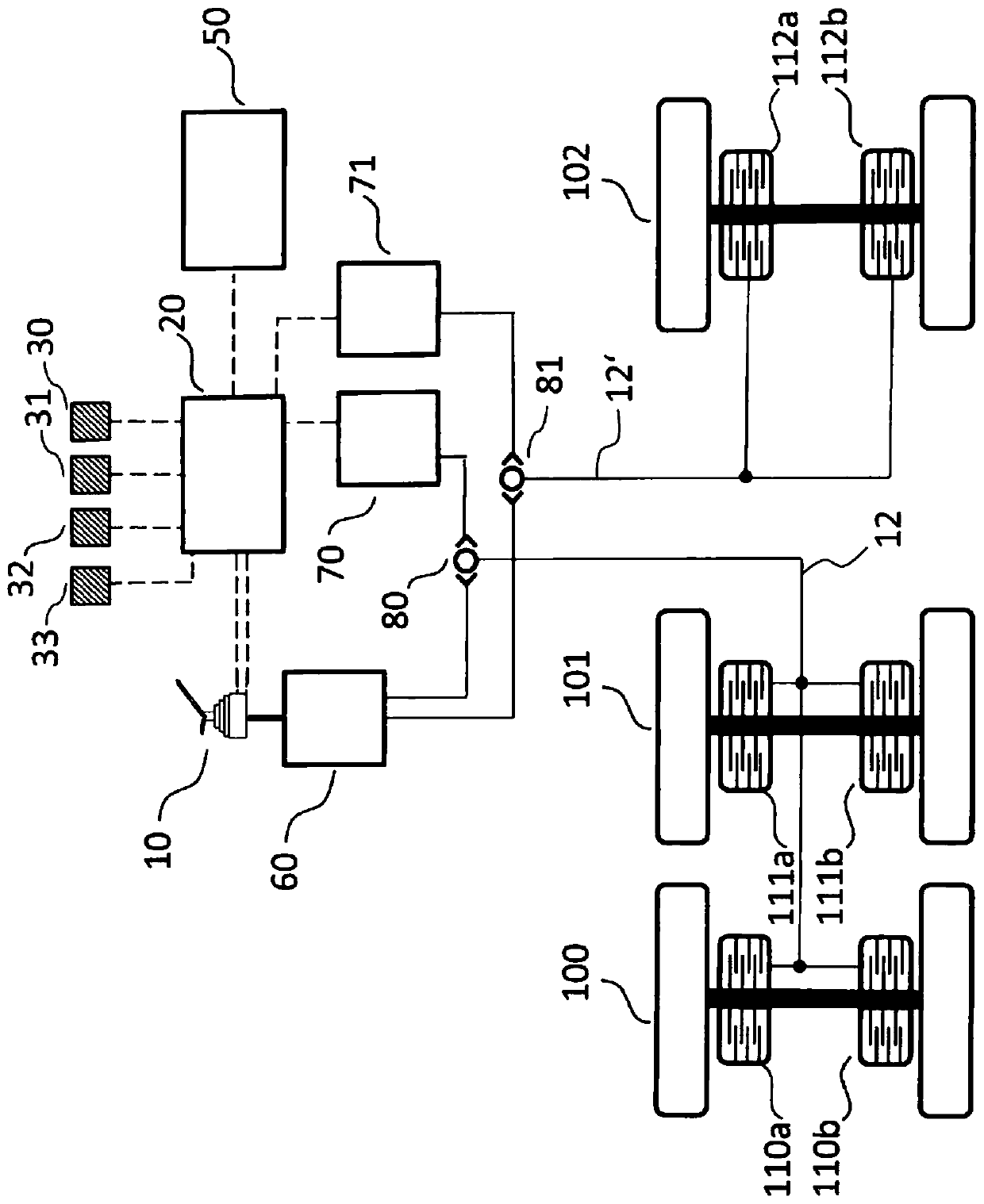

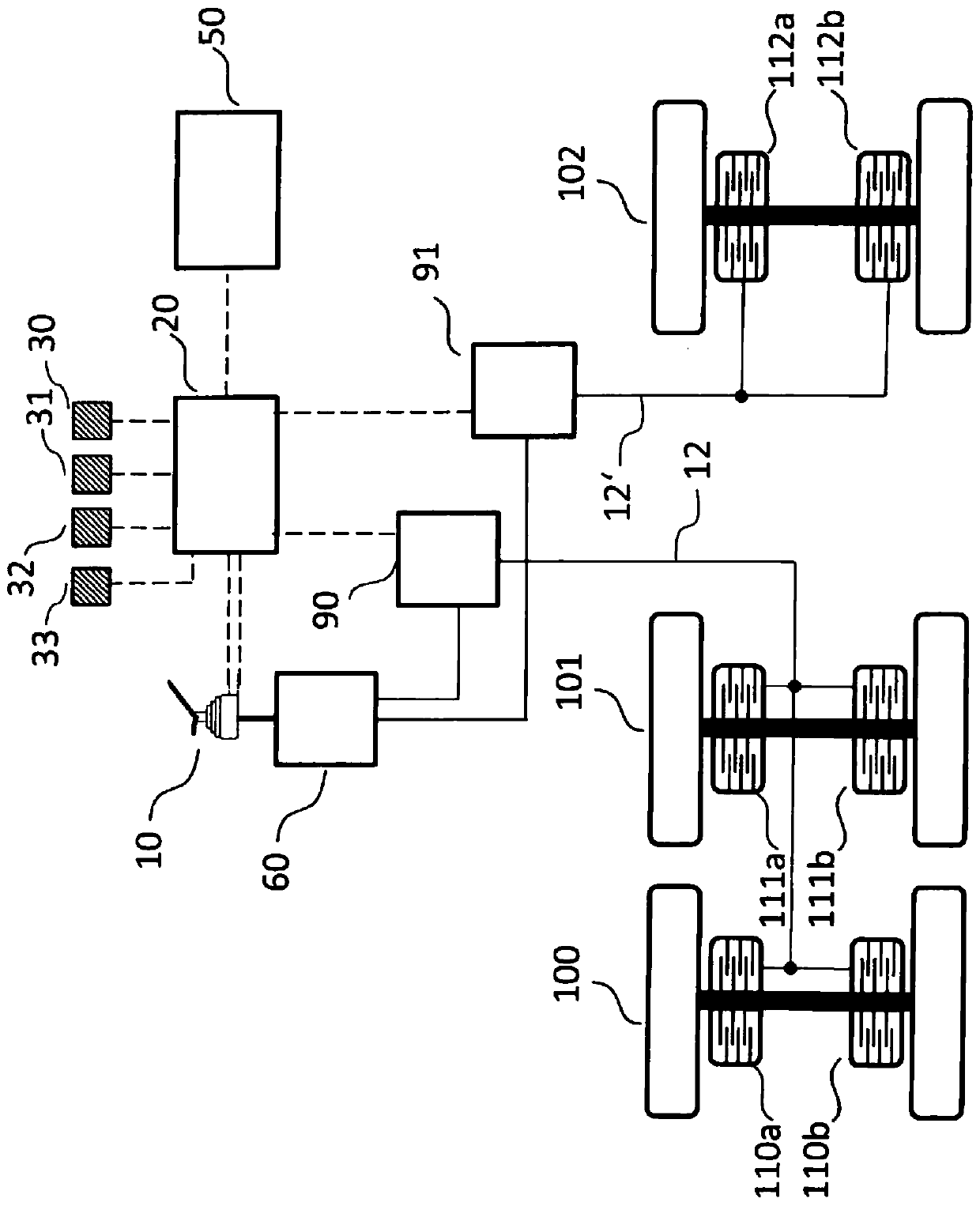

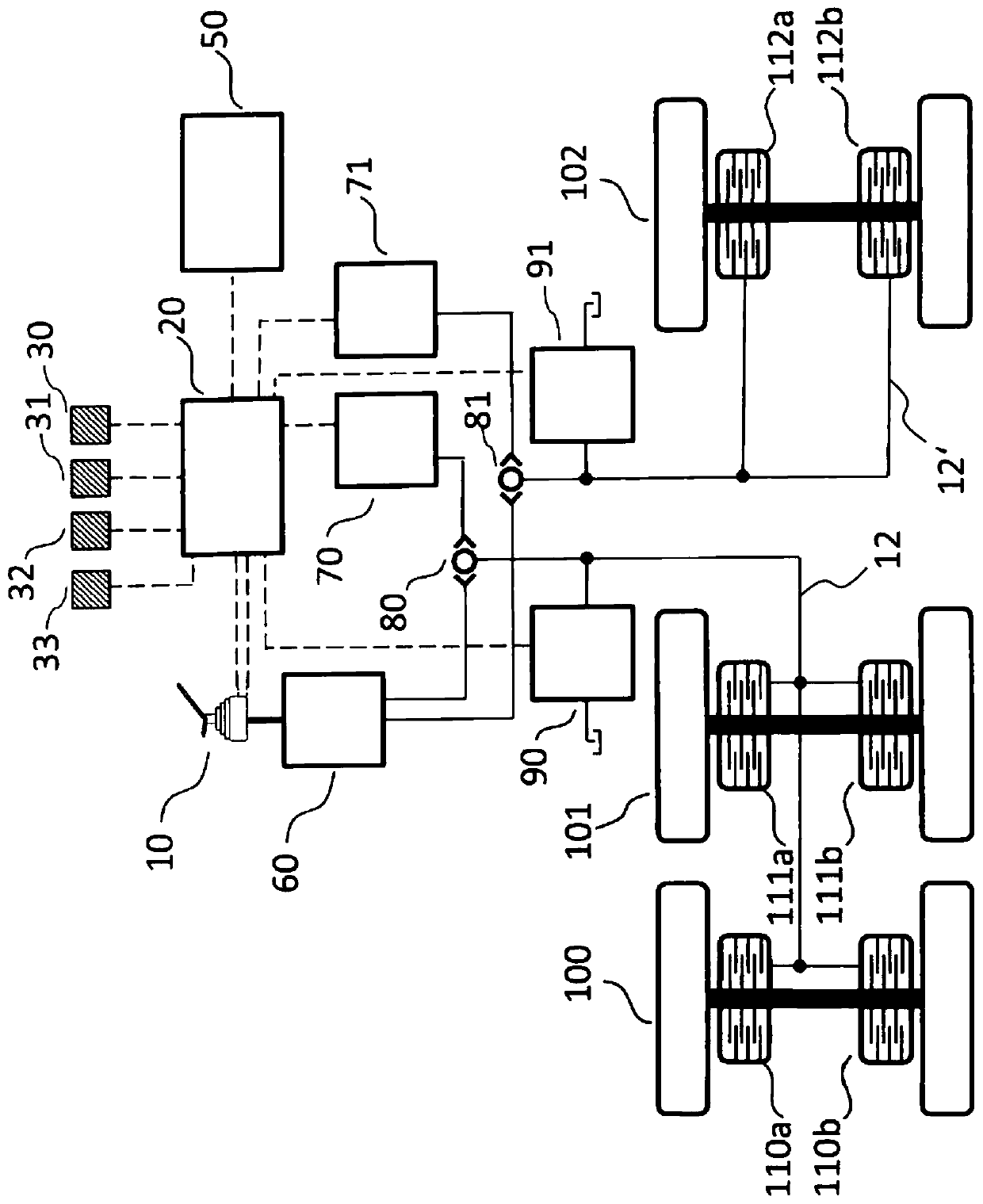

[0030] figure 1 A first embodiment of a braking device for a work machine according to the invention is schematically shown in . The work machine may be an excavator, a dump truck or dump truck, a wheel loader, a flatbed truck, or another type of construction machine. The braking system comprises a plurality of brakes 110a-b, 111a-b, 112a-b arranged on different axles 100, 101, 102 of the work machine, And said plurality of brakes 110a-b, 111a-b, 112a-b is used to brake the respective axle 100, 101, 102 or the differential of the respective axle 100, 101, 102. The brakes 110a-b, 111a-b, 112a-b are actuated via two hydraulic brake circuits 12, 12', wherein brake circuit 12 is associated with brakes 110a-b and 111a-b, and brake circuit 12' is associated with The brakes 112a-b are associated. In this example, axles 100 and 101 may be rear axles, and axle 102 may be a front axle of an articulated steer dump truck.

[0031]The braking arrangement comprises a brake pedal 10 whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com