Lampblack buffering mechanism for range hood

The technology of a range hood and a buffer mechanism is applied in the direction of removing oil fume, application, household stove, etc., and can solve the problems such as the adhesion of the valve plate and the valve body, the large resistance of the oil fume in the public flue, and the easy contamination of the oil fume by the valve plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

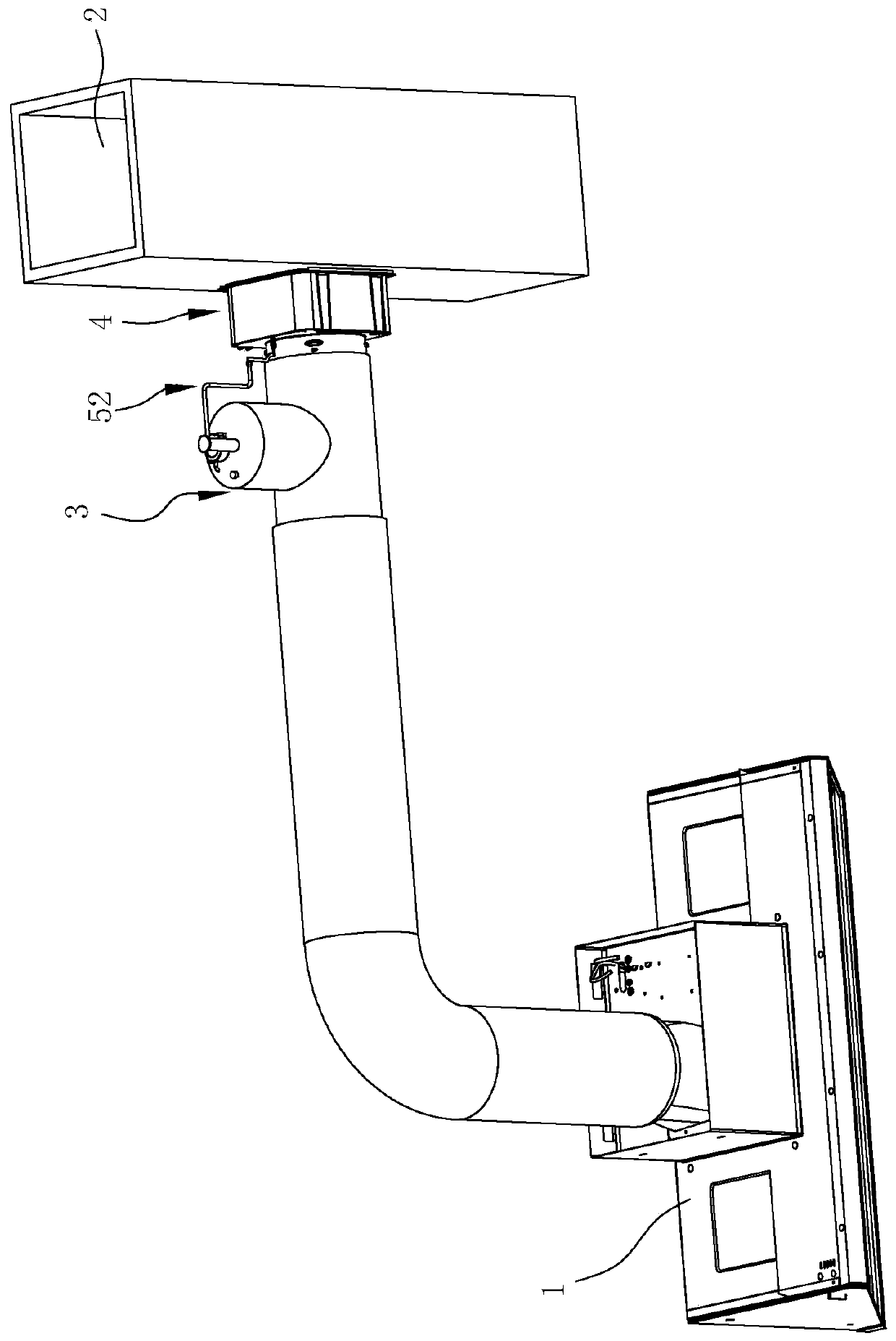

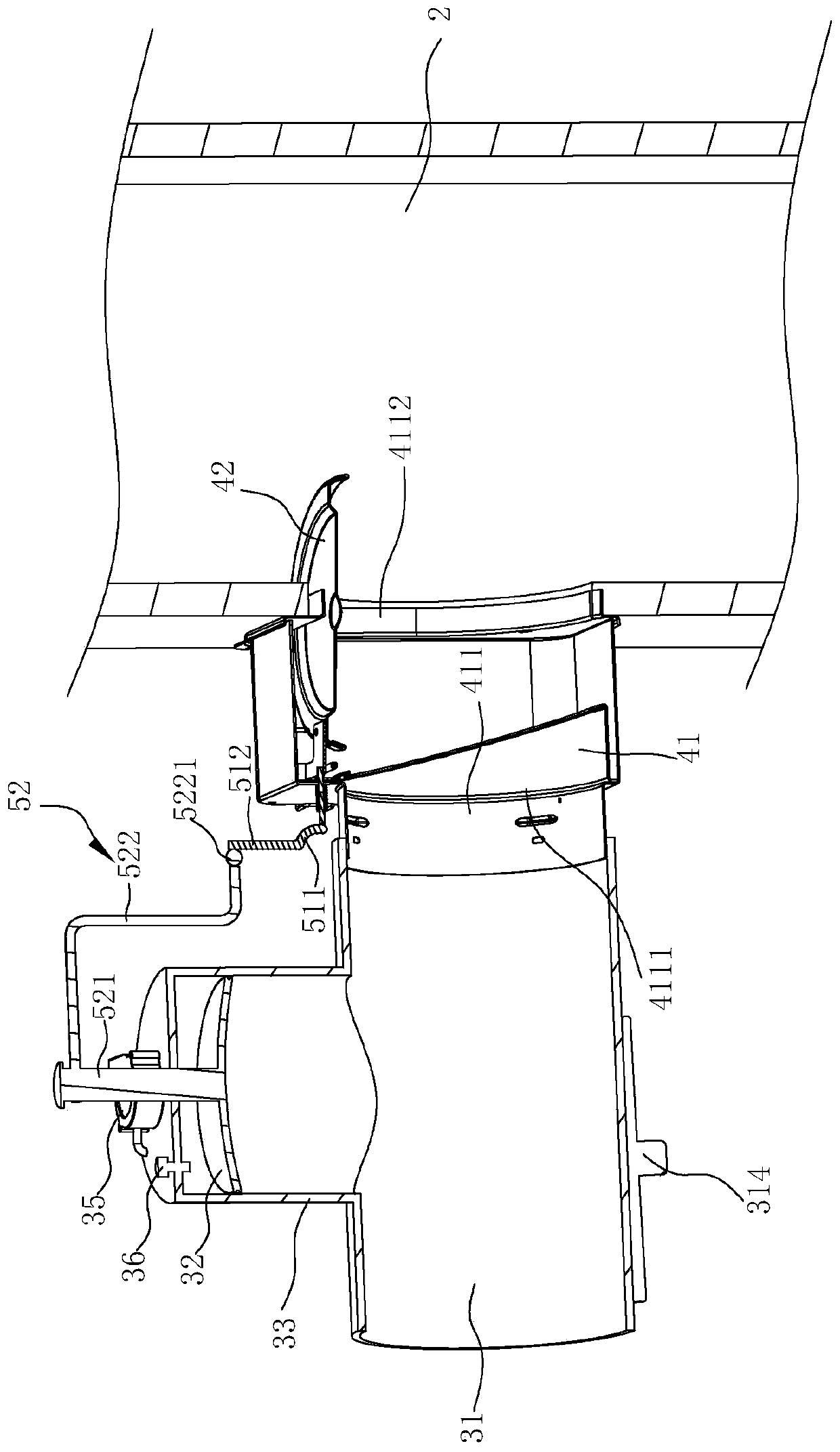

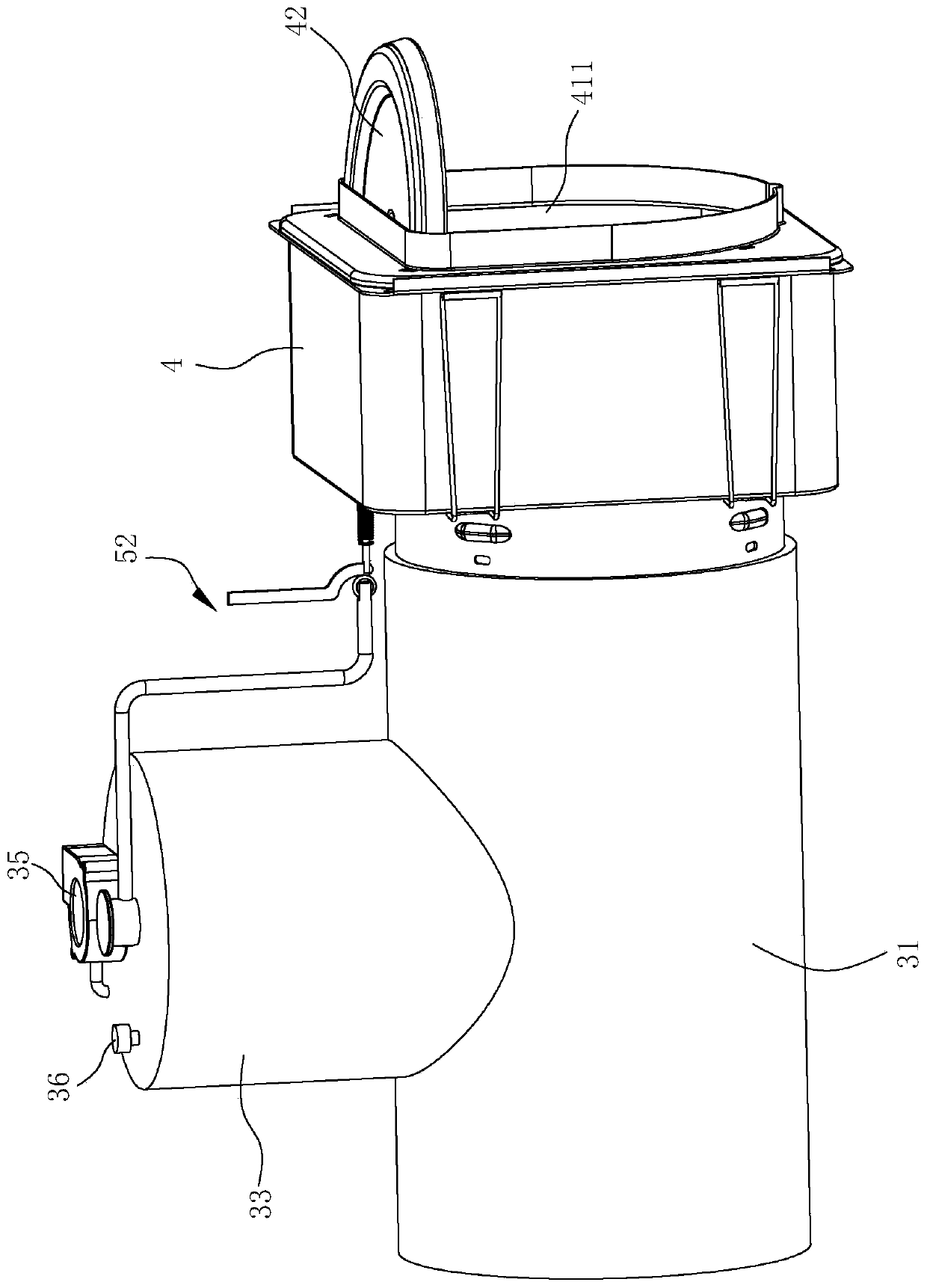

[0039] Such as Figure 1 to Figure 9 As shown, the oil fume buffer mechanism for range hoods according to the embodiment of the present invention includes a check valve 4, an oil fume buffer device 3, a piston 32 and a driving mechanism 5, wherein,

[0040] The check valve 4 includes a valve body 41 and a valve plate 42, wherein the valve body 41 is provided with a connecting frame 43 and a rotating shaft 44 capable of rotating around its own axis, the first end of the connecting frame 43 is relatively fixed to the rotating shaft 44, and the connection The second end of the frame 43 is relatively fixed to the valve plate 42, that is, the valve body 41, the connecting frame 43 and the rotating shaft 44 rotate synchronously. production cost. Moreover, the valve body 41 has a smoke exhaust passage 411, and the smoke exhaust passage 411 has an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com