A preparation method of anti-intestinal adhesion bilayer biogel and bilayer biogel

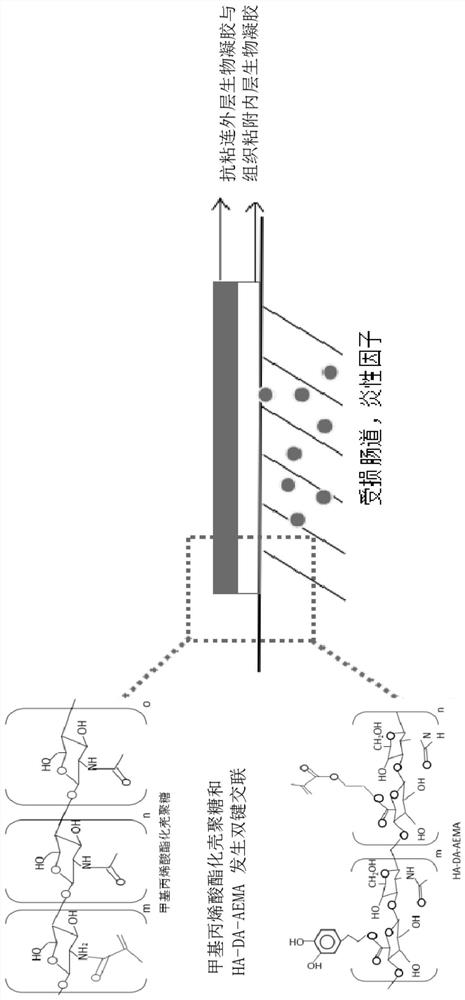

A biological gel and intestinal adhesion technology, applied in the field of biomedicine, can solve problems such as intestinal adhesions that cannot be relieved and have not been resolved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of anti-intestinal adhesion bilayer biogel, comprising the following steps:

[0044] S1: preparing chitosan solution in advance;

[0045] The pre-prepared chitosan solution in S1 is specifically: dissolving chitosan with a mass volume fraction of 3% w / v in 1% acetic acid, stirring with a magnetic stirrer, adjusting the stirrer speed to 1000r / min, Stir for 24h. It should be noted that the mixed solution of chitosan and acetic acid should be shaken evenly at room temperature before stirring with a magnetic stirrer. In addition, the volume of chitosan can be calculated based on the mass-volume ratio of 3% w / v. Personnel in the field are familiar with the process, and will not repeat it here.

[0046] The chitosan described in S1 has a deacetylation degree of 75%, a molecular weight of 310000 g·mol-1, and a viscosity of 800. The higher the degree of deacetylation of chitosan, the better the dissolution of chitosan.

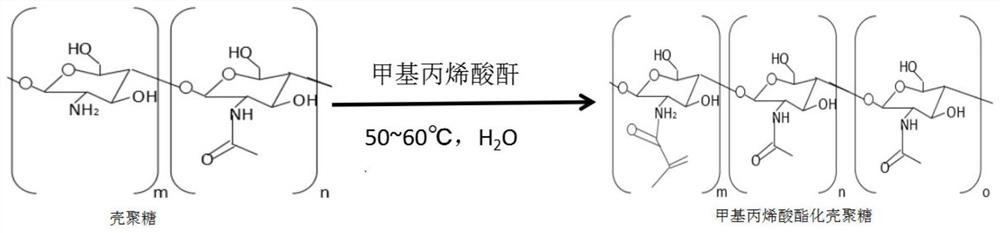

[0047] S2: preparing pure methacry...

Embodiment 2

[0069] A method for preparing an anti-intestinal adhesion double-layer biogel, other features are the same as in Example 1, the difference is that: the pre-prepared chitosan solution in S1 is specifically: a shell with a mass volume fraction of 10% w / v The polysaccharide was dissolved in 5% acetic acid, stirred with a magnetic stirrer at a speed of 1000 r / min, and stirred for 48 hours.

[0070] The chitosan described in S1 has a deacetylation degree of 90%, a molecular weight of 375000 g·mol-1, and a viscosity of 2000.

[0071] Adding methacrylic anhydride dropwise in S2 is specifically: stirring and heating the chitosan solution to 60°C in an oil bath, adding 95% methacrylic anhydride dropwise to the chitosan solution at a speed of 1ml / min with a concentration of Stir with a magnetic stirrer at a speed of 1000r / min for 6h.

[0072] The mass volume concentration of the methacrylated chitosan solution in S3 is 10% w / v.

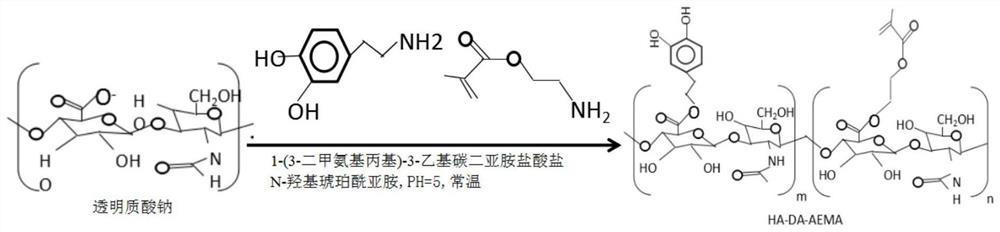

[0073] Weigh respectively 5mmol of 1-(3-dimethylaminopr...

Embodiment 3

[0082] A preparation method of an anti-intestinal adhesion double-layer biogel, other features are the same as in Example 1, the difference is that: the pre-prepared chitosan solution in S1 is specifically: a shell with a mass volume fraction of 5% w / v The polysaccharide was dissolved in 3% acetic acid, stirred with a magnetic stirrer, the speed of the stirrer was adjusted to 1000r / min, and stirred for 36h.

[0083] The chitosan described in S1 has a deacetylation degree range of 83%, a molecular weight of 350000 g·mol-1, and a viscosity of 1500.

[0084] Adding methacrylic anhydride dropwise in S2 is specifically: stirring and heating the chitosan solution to 55° C. in an oil bath, adding 94.5% methacrylic anhydride dropwise to the chitosan solution at a speed of 0.75 ml / min, Stir with a magnetic stirrer at a speed of 1000r / min, and stir for 5h.

[0085] The mass volume concentration of the methacrylated chitosan solution in S3 is 6% w / v.

[0086] Weigh respectively 4.5mmol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com