A kind of finishing method of welded pipe

A welded pipe, to-be-processed technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as low efficiency, tool wear and scraping quality, and achieve the effect of improving quality and improving scraping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

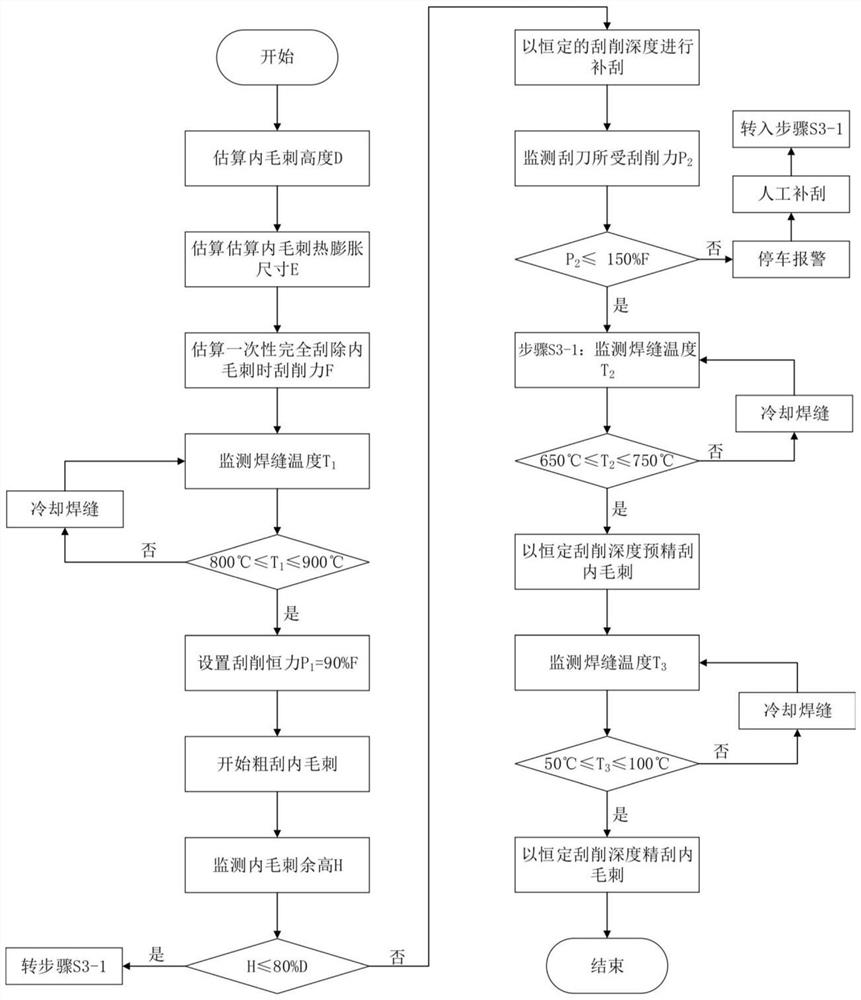

[0048] Such as figure 1 As shown, the present invention provides a method for finishing the welded pipe. In order to realize the precise scraping of the internal burrs of the welded pipe during the finishing process and improve the accuracy and quality of the removal of the internal burrs of the welded pipe, the internal burr scraping is divided into preparation, rough scraping, There are four stages of pre-fine scraping and fine scraping, including the following steps:

[0049] S1: In the preparation stage, use the welded pipes produced in the laboratory for data collection;

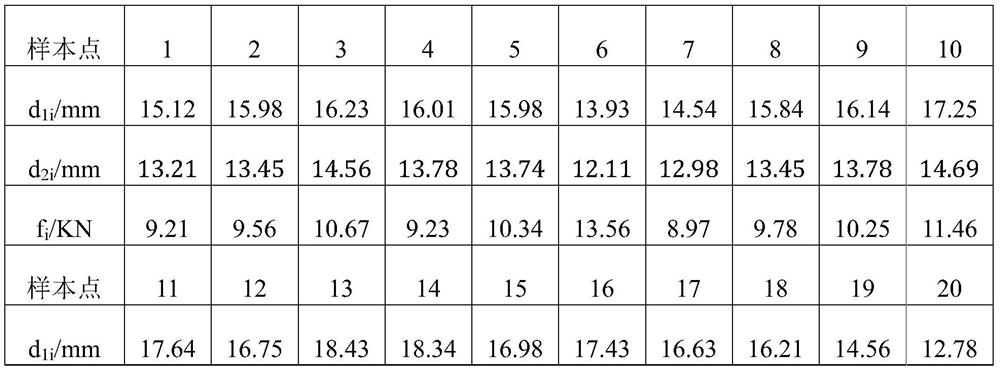

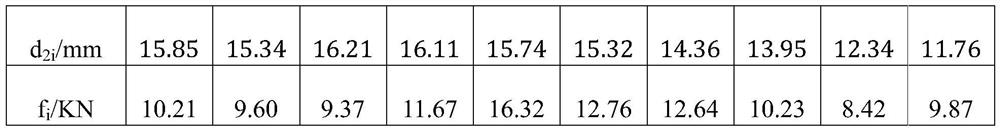

[0050] S1-1: Set the pre-finish scraping temperature and fine scraping temperature, and take samples of the burr height in the trial production welded pipe at the set pre-finish scraping temperature and fine scraping temperature respectively, and obtain samples at the pre-finish scraping temperature Observation value of burr height in point d 1i And the observed value d of the burr height in the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com