Stacking transferring device for woodworking processing

A transfer device and palletizing technology, which is applied in the direction of transportation and packaging, conveyor control devices, object stacking, etc., can solve the problems of high labor intensity, small workload, and no auxiliary carpentry, so as to reduce the intensity of human work, Improved work efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

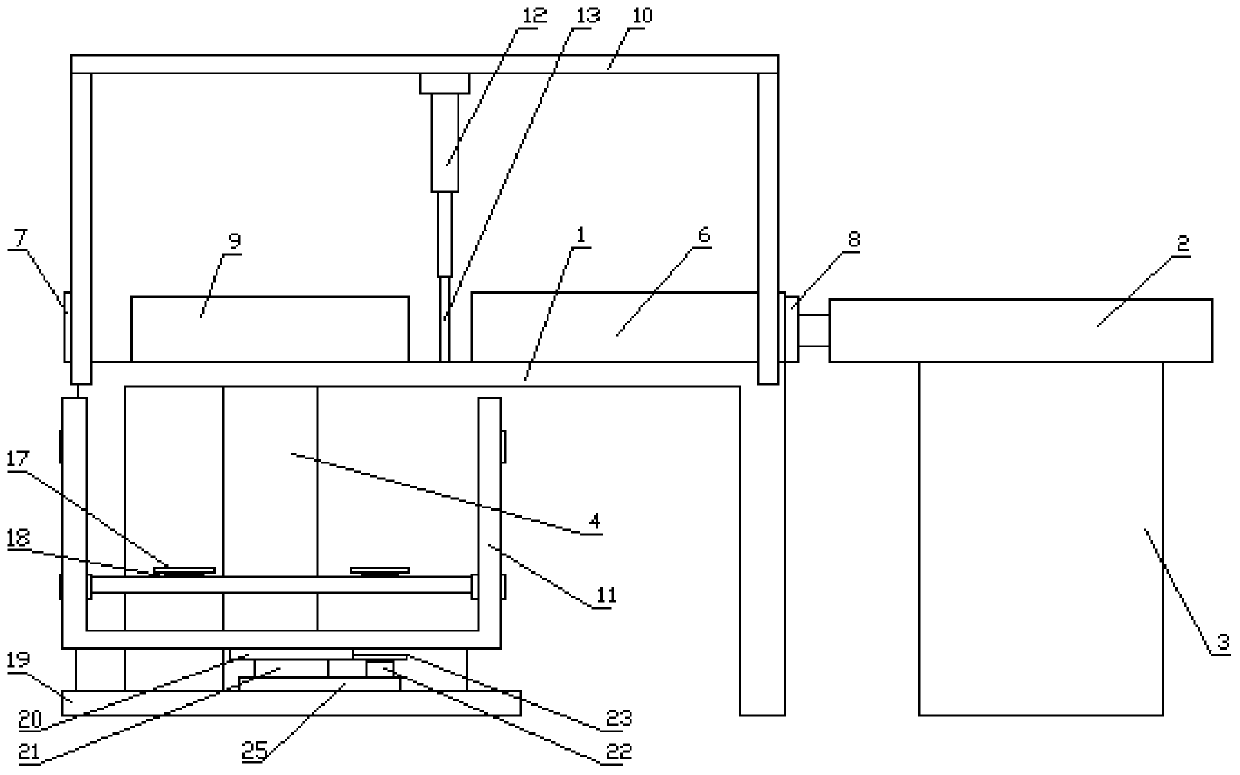

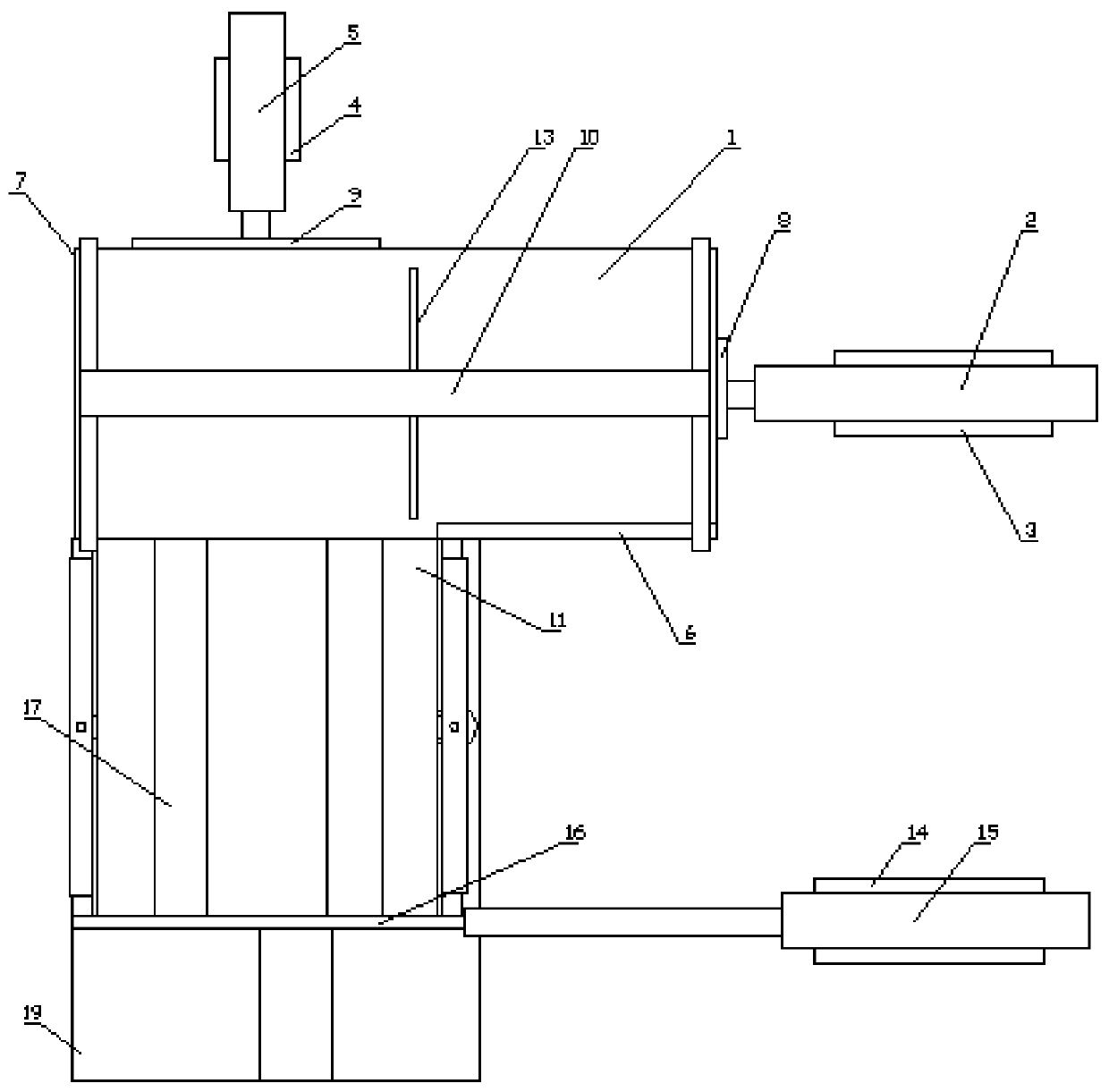

[0033] Such as Figure 1 to Figure 2 As shown, a kind of palletizing transfer device for woodworking provided by the present invention includes workbench 1, and also includes:

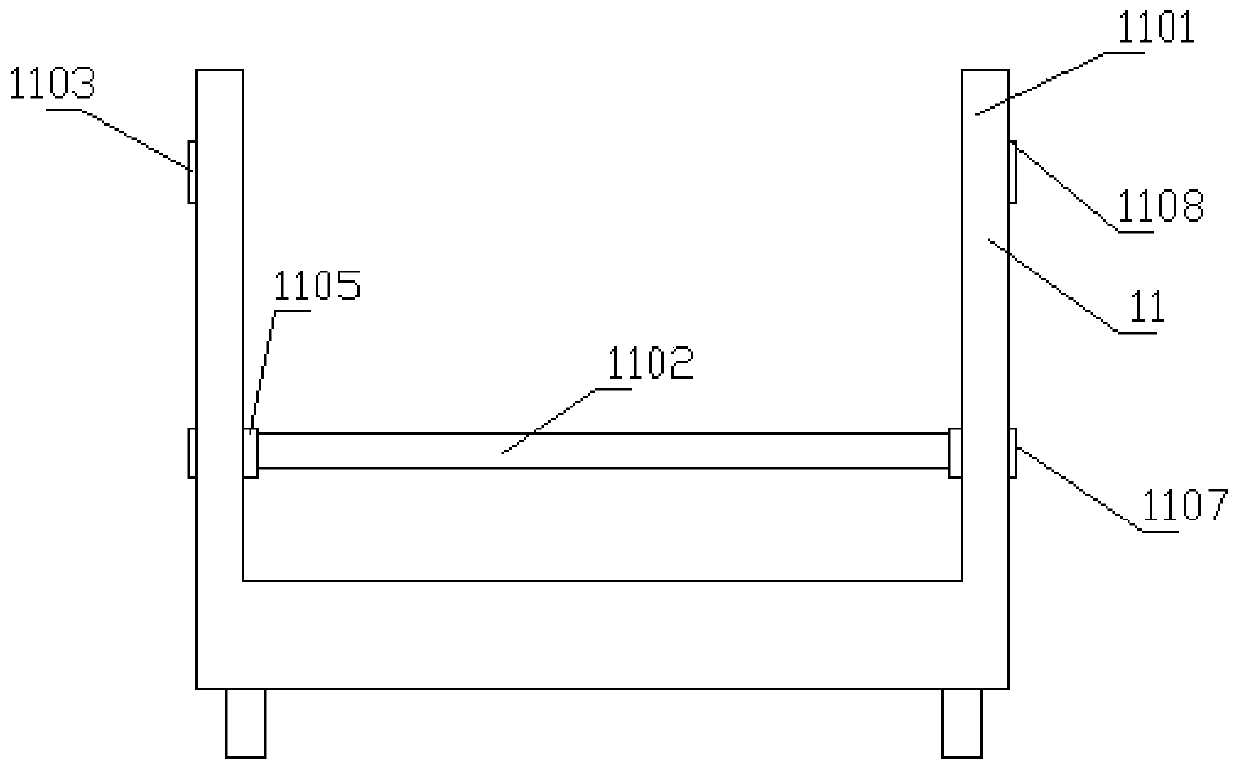

[0034] The monolithic structure 1 arranged on the workbench 1 is used for arranging the timber neatly in rows, and its structure includes:

[0035] The first pushing device is arranged on one side of the workbench 1;

[0036] Wherein, the first pushing device includes a support 3 fixed on the ground for providing support, a hydraulic cylinder 2 is fixed above the support 3, the center line of the hydraulic cylinder 2 is perpendicular to the limit plate 7, and the hydraulic pressure The end of the piston rod of cylinder-2 is fixedly connected with the push pedal-8 that is used to promote timber to move, and the center line of the piston rod of hydraulic cylinder-2 is perpendicular to push pedal-8.

[0037] Limiting plate one 7 is vertically fixed on the table top of the workbench 1, and is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com