Air spray injection cooling device for continuous annealing cooling of strips

A water mist spraying and cooling device technology, which is applied in the field of metallurgy, can solve problems such as easy deformation, uneven cooling, and poor stress relief effect, and achieve the effect of keeping the shape unchanged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

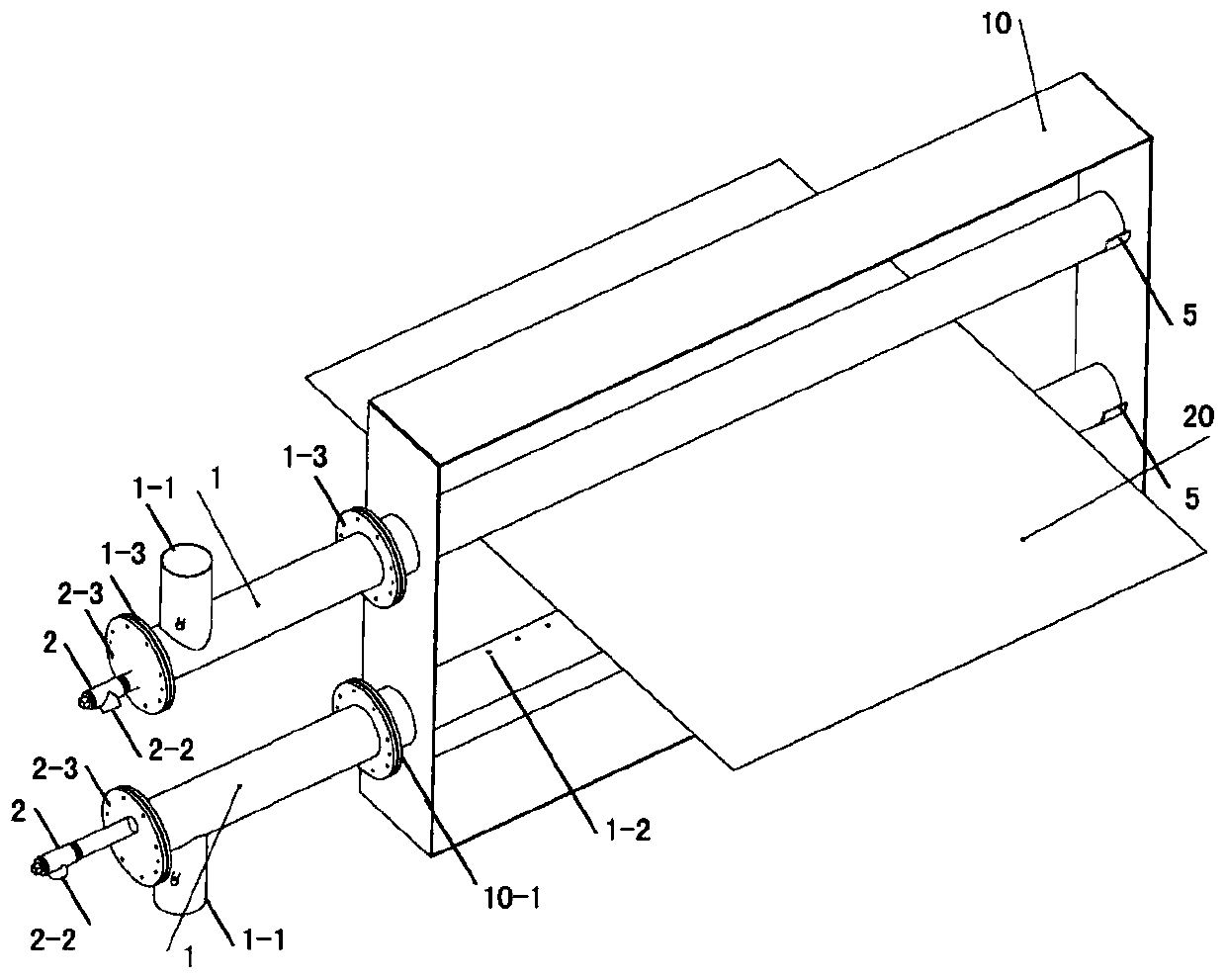

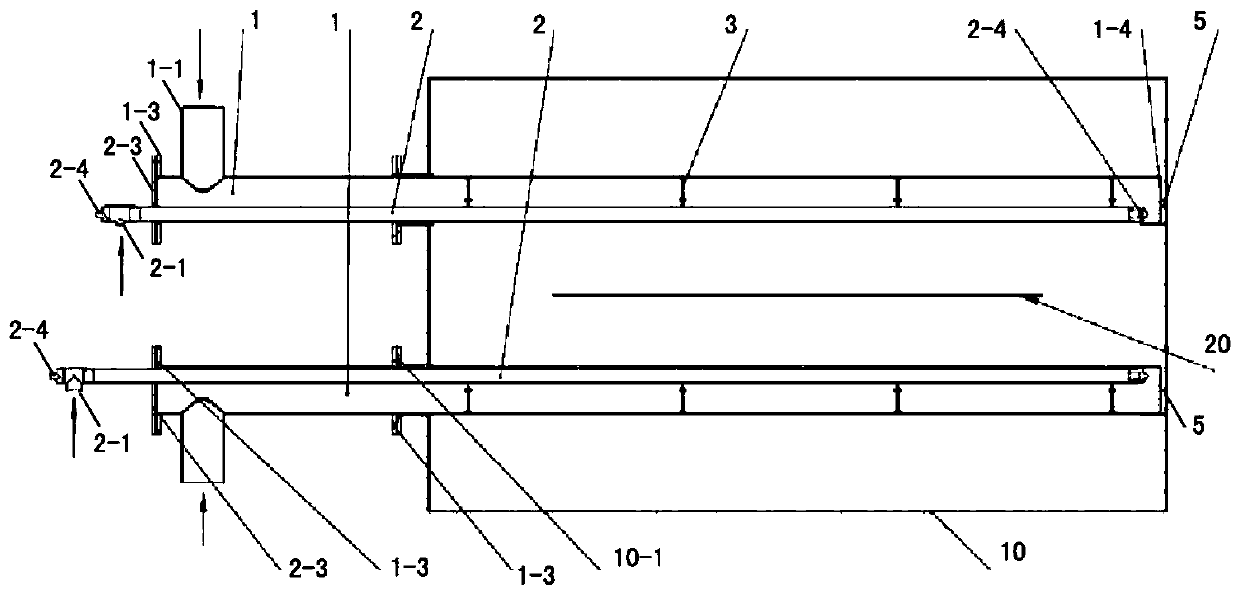

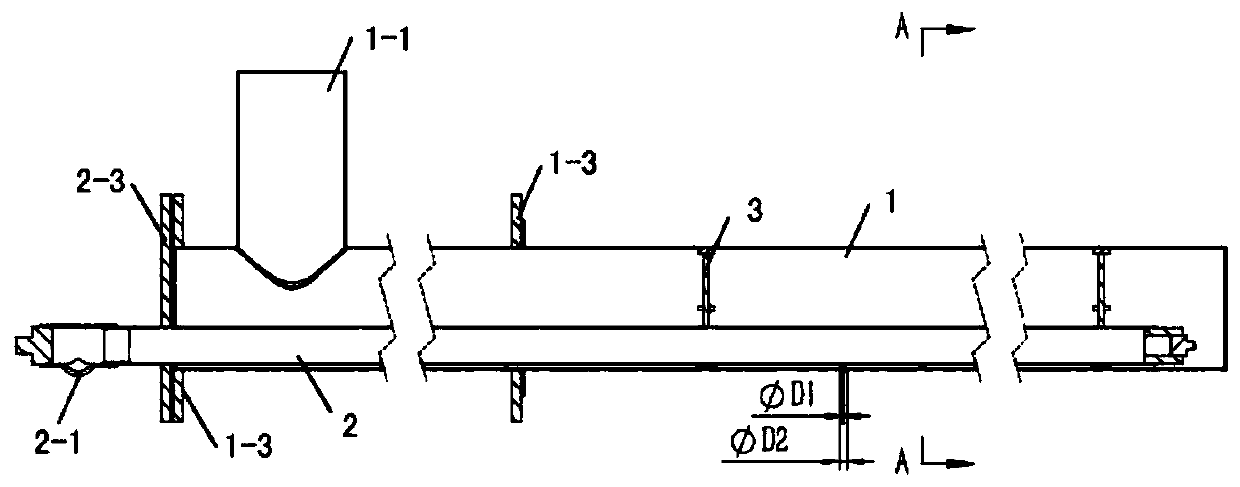

[0037] refer to Figure 1-Figure 2, the strip continuous annealing cooling air water mist spray cooling device that concrete embodiment 1 of the present invention relates to, comprises box body 10 and at least two air water mist injectors arranged in box body 10, box body 10 is arranged on the strip material At the continuous annealing cooling station; the air and water mist sprayers are even numbers, and are distributed up and down in the box 10, forming an upper and lower opposite air and water mist spray structure, that is, forming a top-to-bottom and bottom-to-top The double-sided uniform multi-point surface spray structure; the front end of the air water mist sprayer is fixedly connected to the outer wall of the box body 10 through the box body flange 10-1, and the rear end is fixedly connected to the inner wall of the box body 10 through the arc-shaped support plate 5, The box body flange 10-1 is connected with an air pipe flange 1-3, forming an integrated connection str...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap