Flow channel for separating and discharging condensate

A condensate and flow channel technology, applied in the field of flow channels, can solve the problem of condensate reaching the compressor or compactor, compressor impeller damage, etc., and achieve the effect of effective use of structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

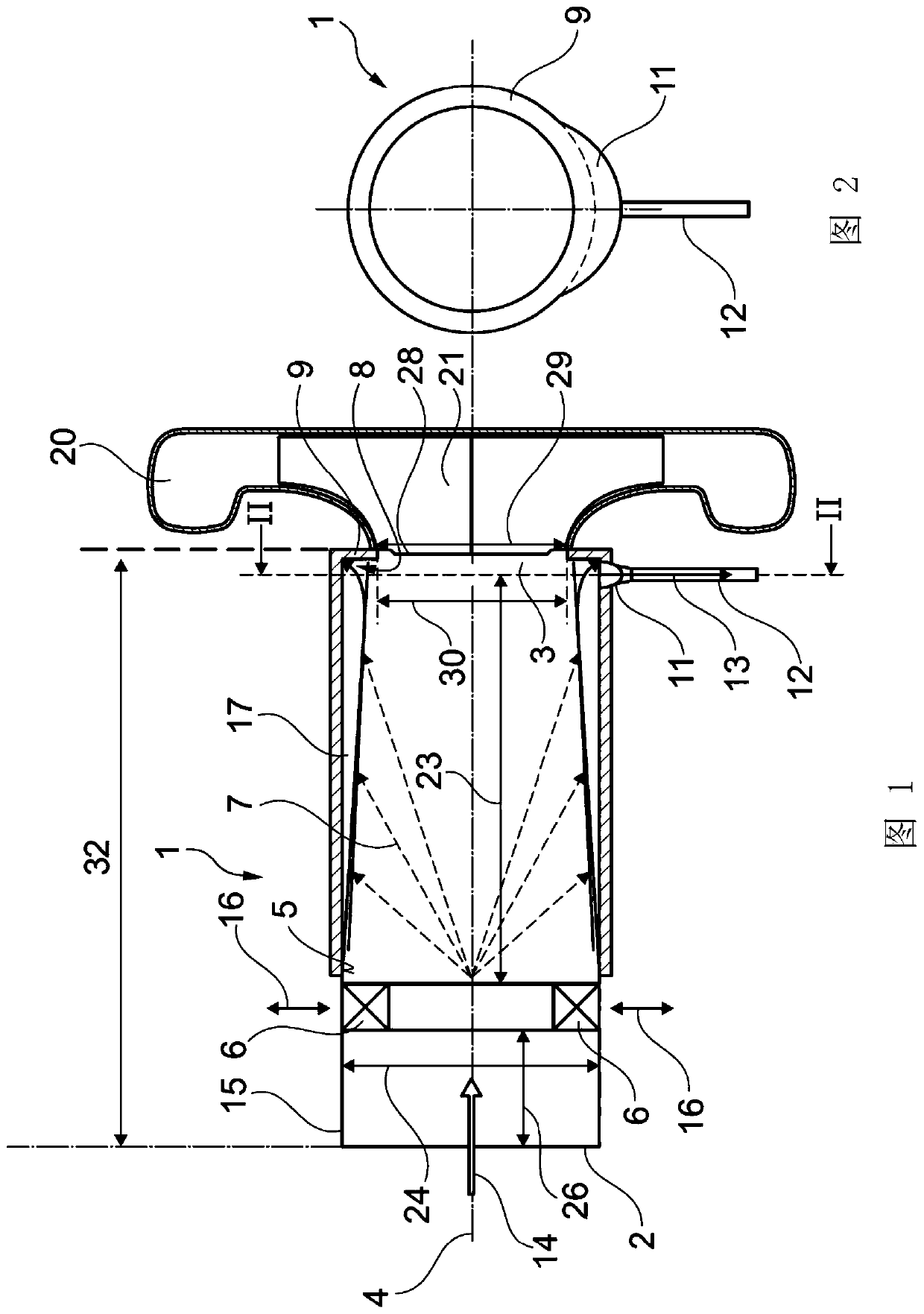

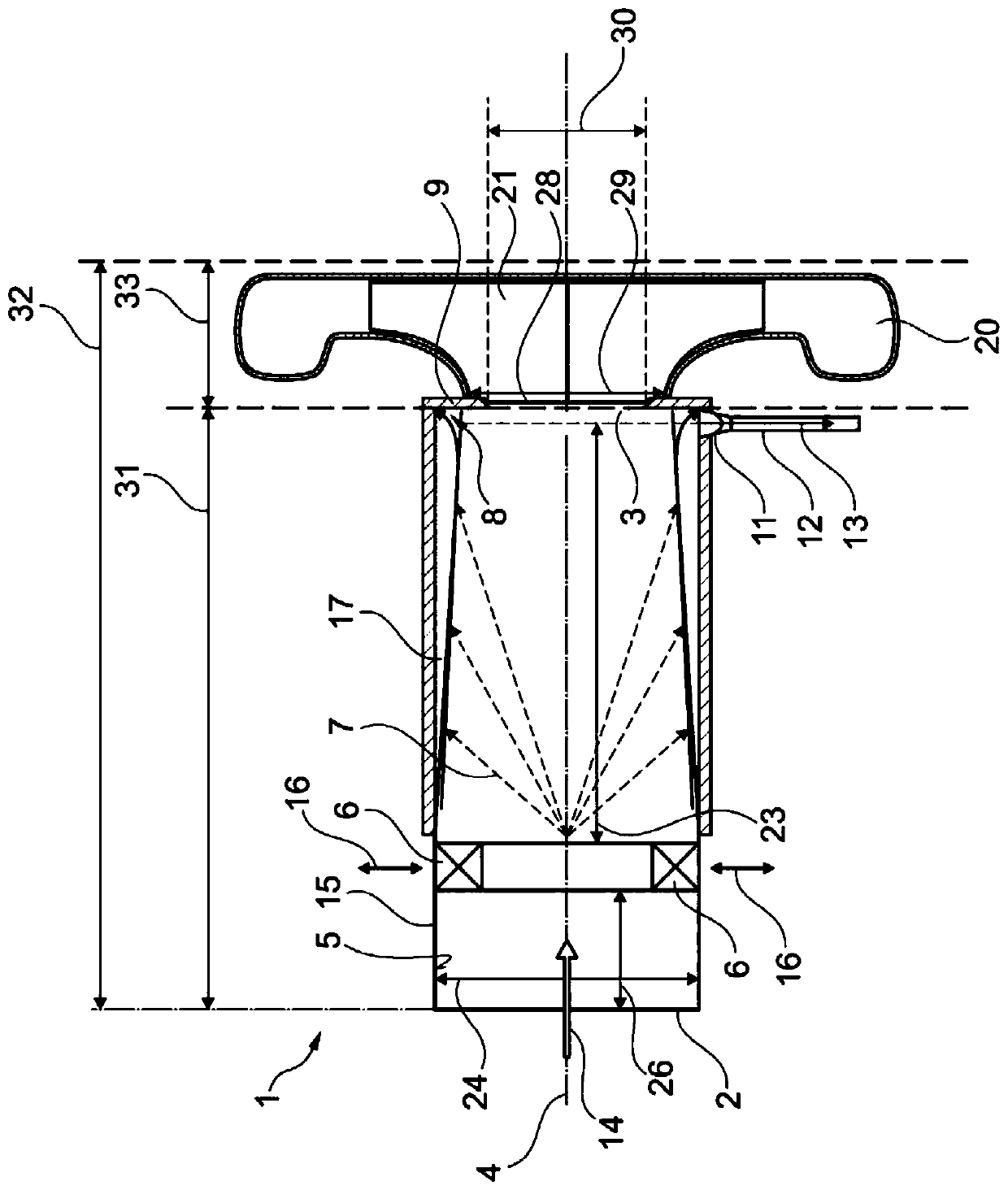

[0027] Figure 1 to Figure 3 The shown flow channel 1 according to the invention comprises an inlet 2 , an outlet 3 and a central axis 4 . In the variant shown, the central axis 4 is both the central axis of the inlet 2 and the central axis of the outlet 2 . As an alternative to the variant shown, the central axes of the inlet 2 and the outlet 3 can also differ from each other, so that the flow channel 1 can also have one or more curves. The flow channel 1 according to the invention also comprises an inner surface 5 and an outer wall 15 .

[0028]At least one turbulence generator 6 is arranged downstream of the inlet 2 and upstream of the outlet 3 . The at least one turbulence generator 6 can be arranged, for example, directly at the inlet 2 or at a distance 26 of less than one third of the length of the flow channel 1 . At least one turbulence generator 6 is displaceable in radial direction. This is indicated by arrow 16 . Thus, at least one turbulence generator 6 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com