A preliminary cleaning device for livestock farm wool using centrifugal treatment

A technology of centrifugal treatment and preliminary cleaning, applied in the direction of animal loose hair fiber washing/scouring, etc., can solve the problems of insufficient technical consideration, wool separation, and insufficient cleaning, and achieve the effect of improving cleaning quality and improving cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

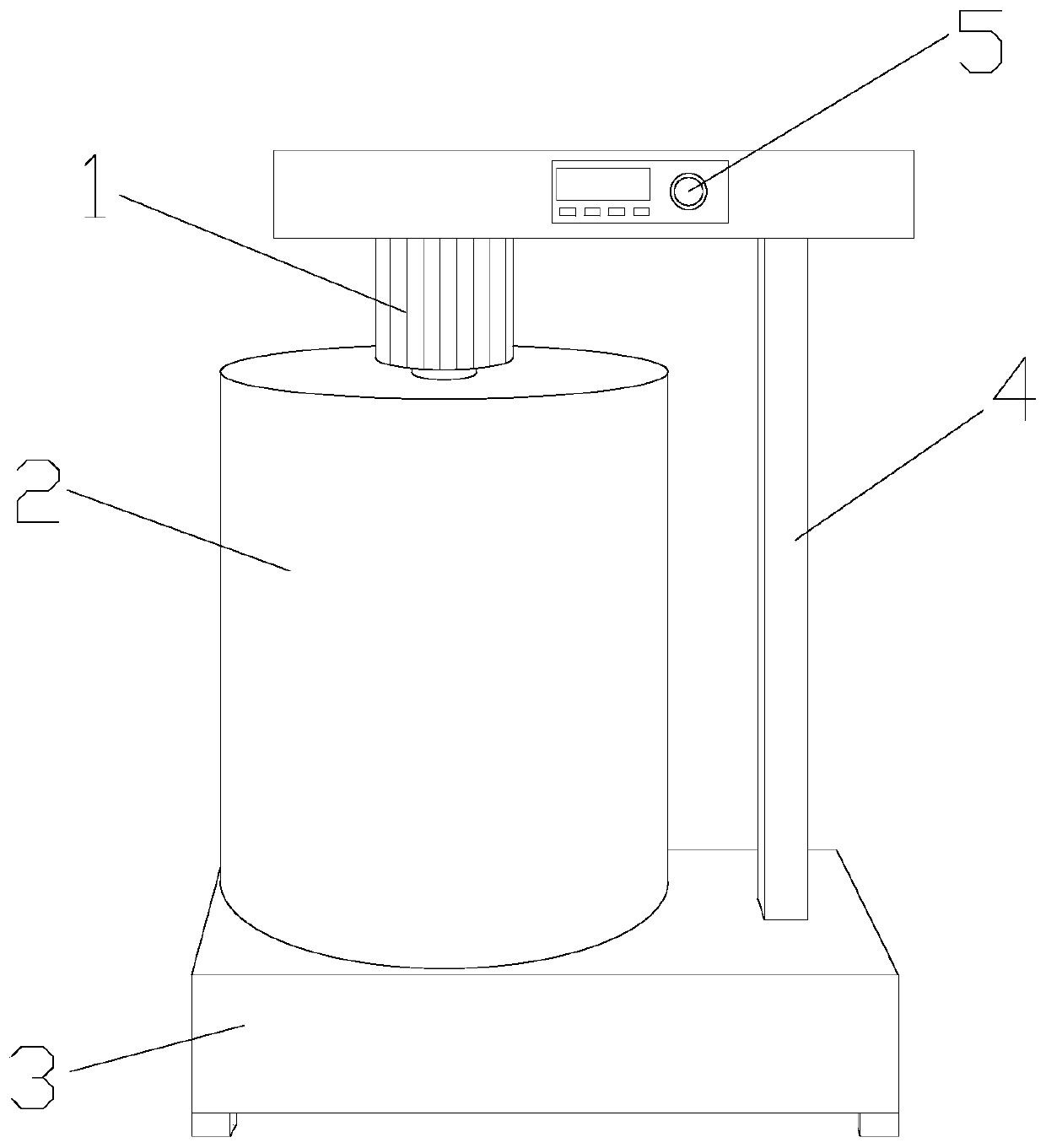

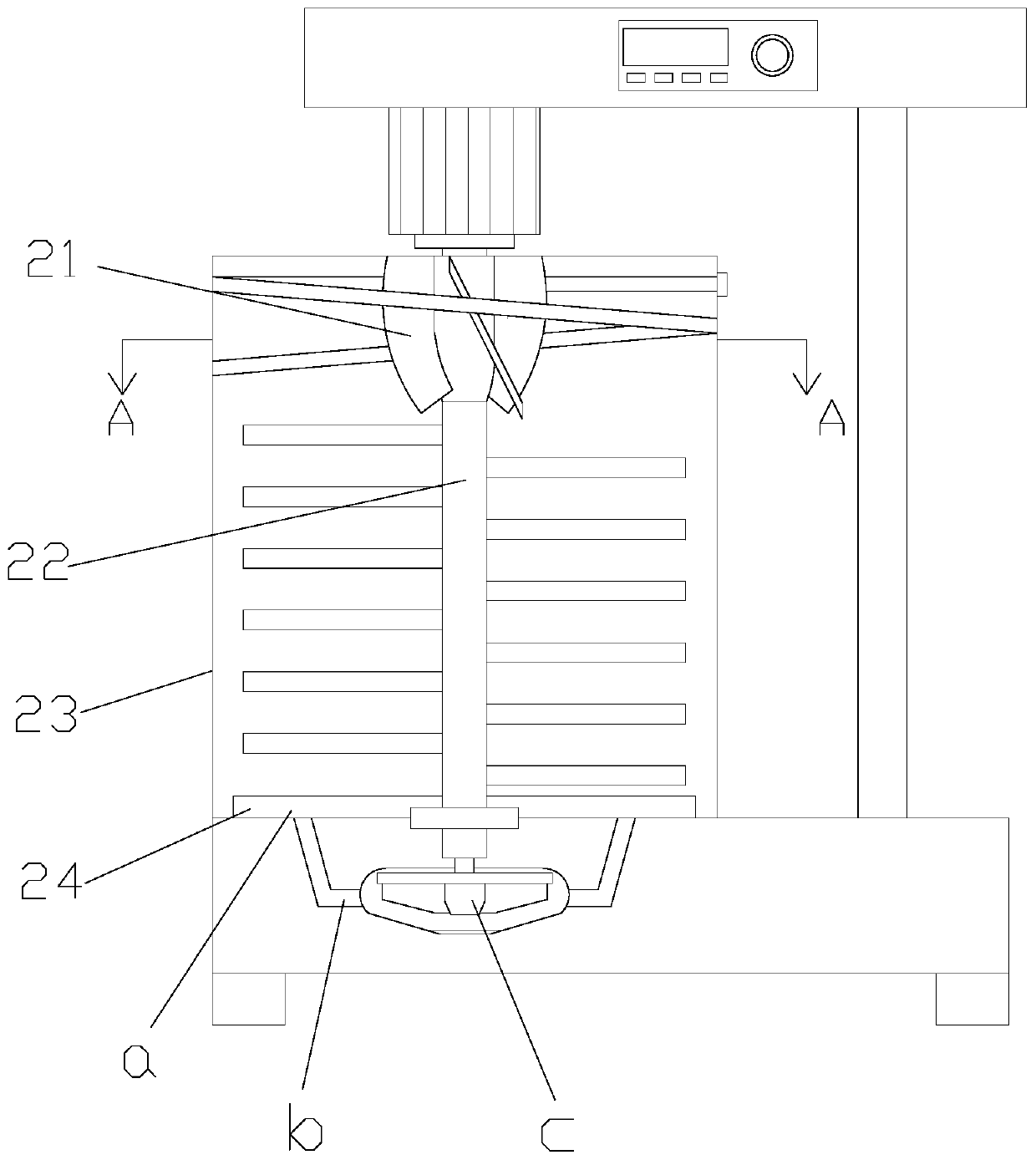

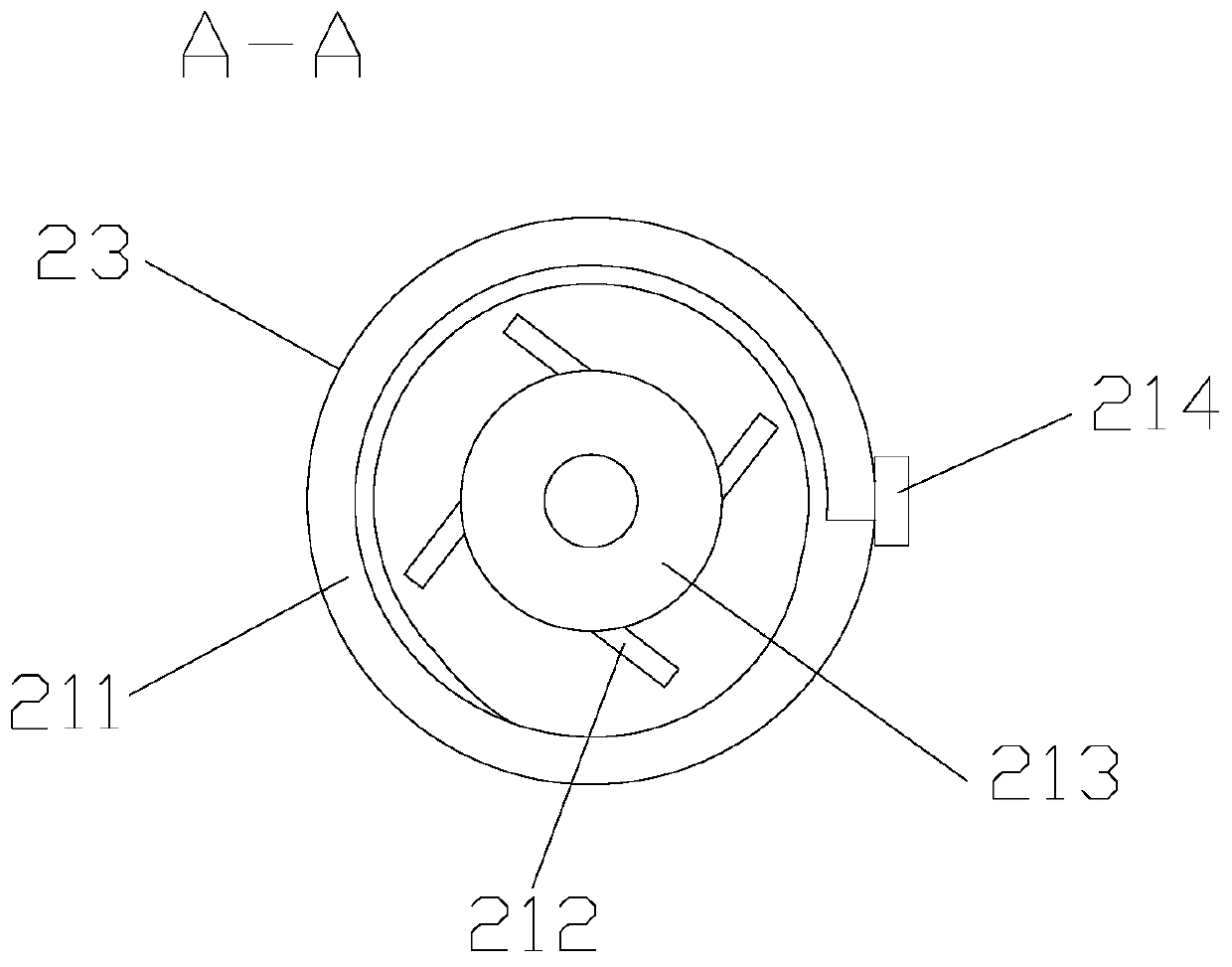

[0025] see Figure 1-Figure 2 , the present invention provides a preliminary cleaning device for livestock farm wool that adopts centrifugal treatment. The seat 3 has a rectangular structure and is parallel to the horizontal plane. The wool cleaning tank 2 is placed on the left end of the upper surface of the tank support seat 3. The right ends of the surface are welded together, the driving motor 1 is installed under the left end of the motor fixing frame 4 and is mechanically connected with the wool cleaning tank 2, the control panel 5 is nested on the top of the front of the motor fixing frame 4, and the wool cleaning tank body 2. It consists of a centrifugal cleaning mechanism 21, a wool stirring rod 22, a tank shell 23, and an airflow generating device 24. The tank shell 23 is a hollow cylindrical structure and is vertically installed on the left end of the upper surface of the tank support seat 3. The centrifugal The cleaning mechanism 21 is located at the top of the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com