Power transmission line robot capable of automatically adjusting postures and automatic posture adjusting method

A transmission line, automatic adjustment technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems that affect the working angle and walking safety of the whole machine, affect the battery life of the whole machine, portability, large volume and weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

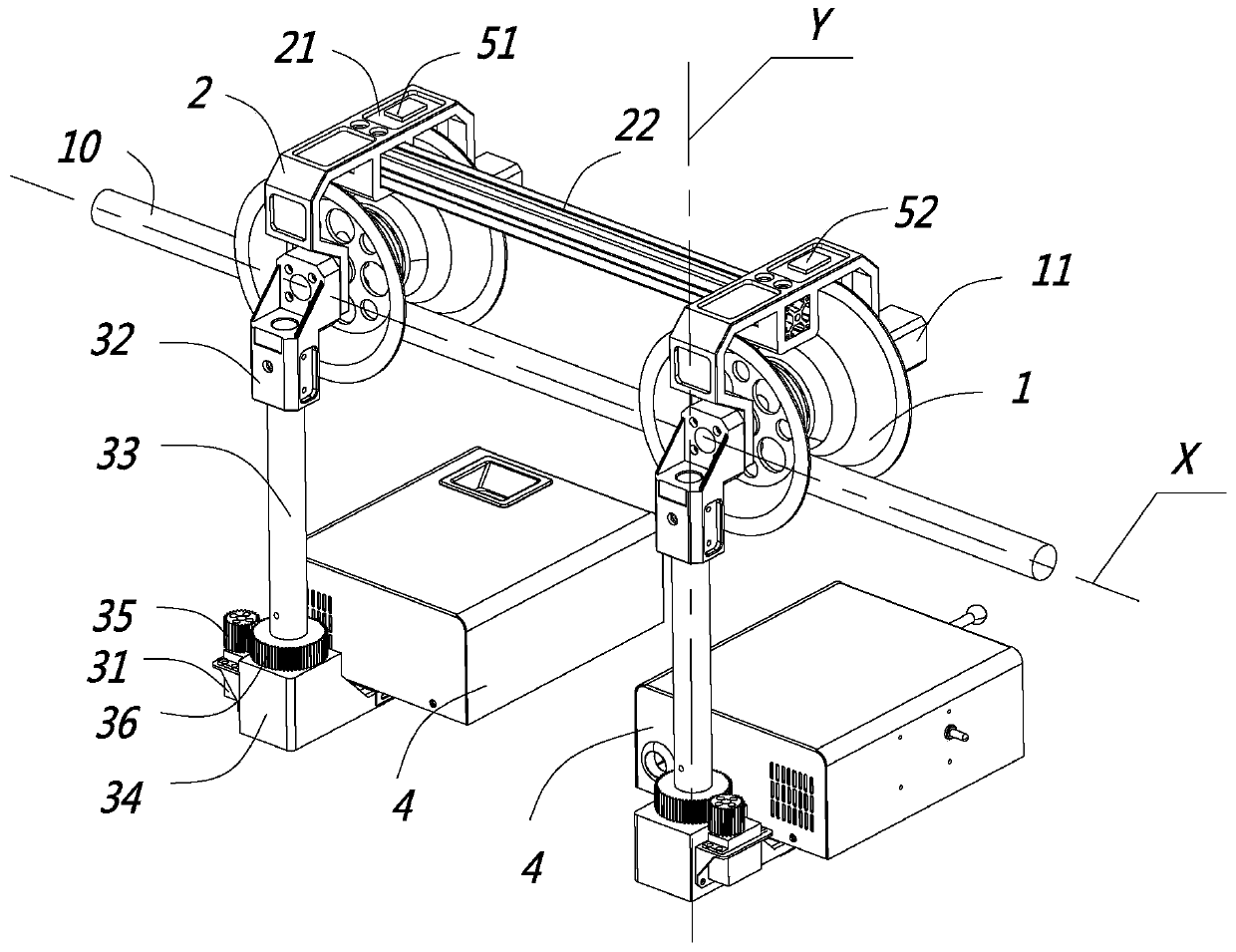

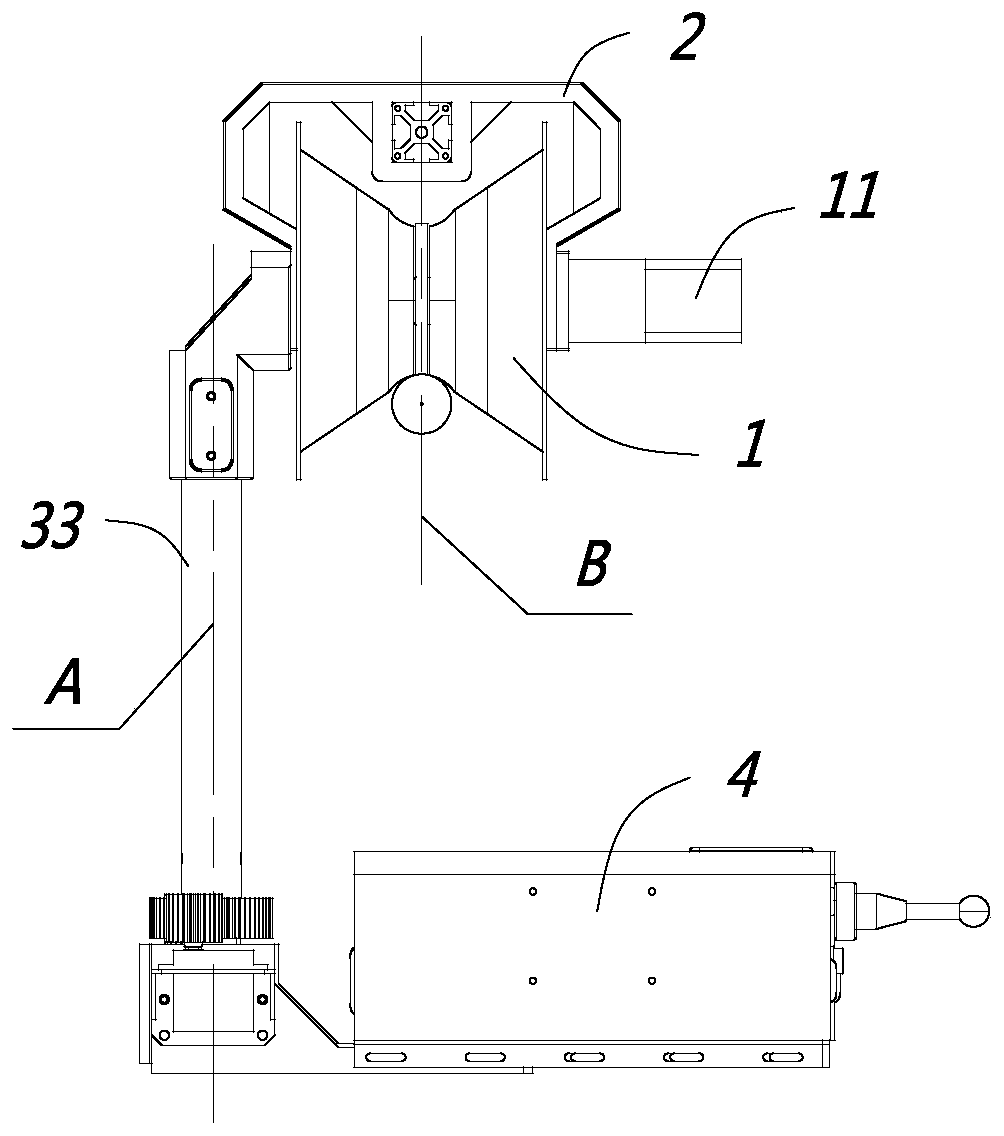

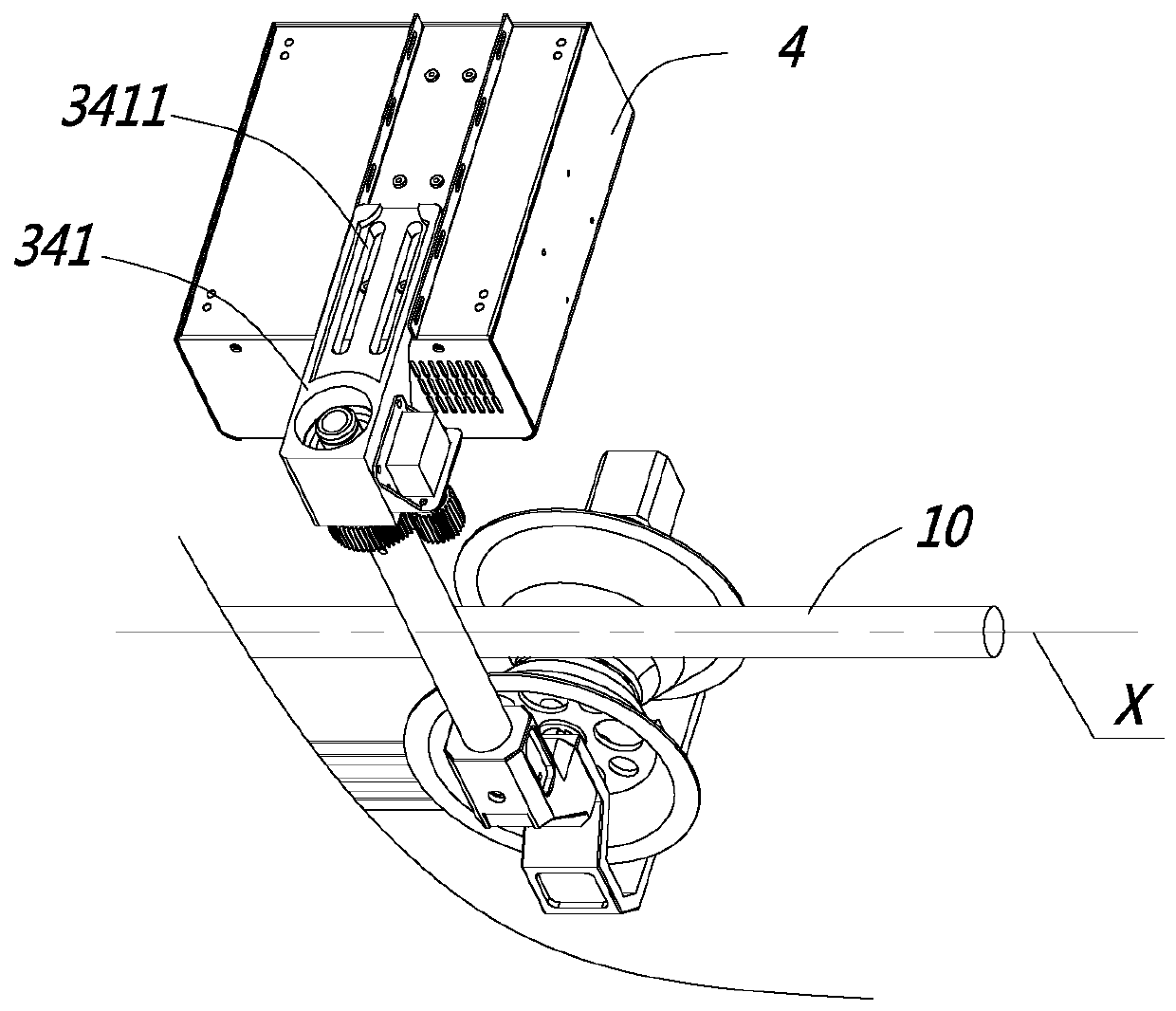

[0034] like Figure 1 to Figure 3 As shown, this embodiment is a power transmission line robot with automatic posture adjustment, including an electric control box 4 and two walking wheels 1, the walking wheels 1 are usually V-shaped wheels, and the walking wheels 1 are used to hang on the power transmission line 10, the travel wheel 1 is connected with a travel motor 11, and the travel motor 11 drives the travel wheel 1 to rotate, thereby driving the entire transmission line robot to walk on the transmission line 10, and each travel wheel 1 is provided with a travel wheel bracket 2 The road wheel 1 is rotatably mounted on the road wheel bracket 2, at least one of the two road wheel brackets 2 is equipped with an angle sensor, and at least one of the two road wheel brackets 2 is provided with a rotation mechanism below, The line connecting the two road wheels 1 is the walking axis X, the rotating mechanism includes a rotating central axis Y, the rotating central axis Y is perp...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that the angle sensor in this embodiment only detects the horizontal angle in the lateral direction, because the balance degree in the lateral direction has a greater impact on the transmission line robot, and the balance degree in the longitudinal direction has a greater impact on the power transmission line. Line robots have relatively little impact.

[0054] In this embodiment, the first rotating mechanism and the second rotating mechanism rotate in opposite directions at the same time.

[0055] In this embodiment, there may be only one angle sensor, and of course there may be two angle sensors, but both of these two angle sensors are used to detect the lateral horizontal angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com