Screen cleaning brush

A technology for cleaning brushes and screens, which is applied in the field of screens and can solve problems such as low cleaning efficiency of screens and damage to the main shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

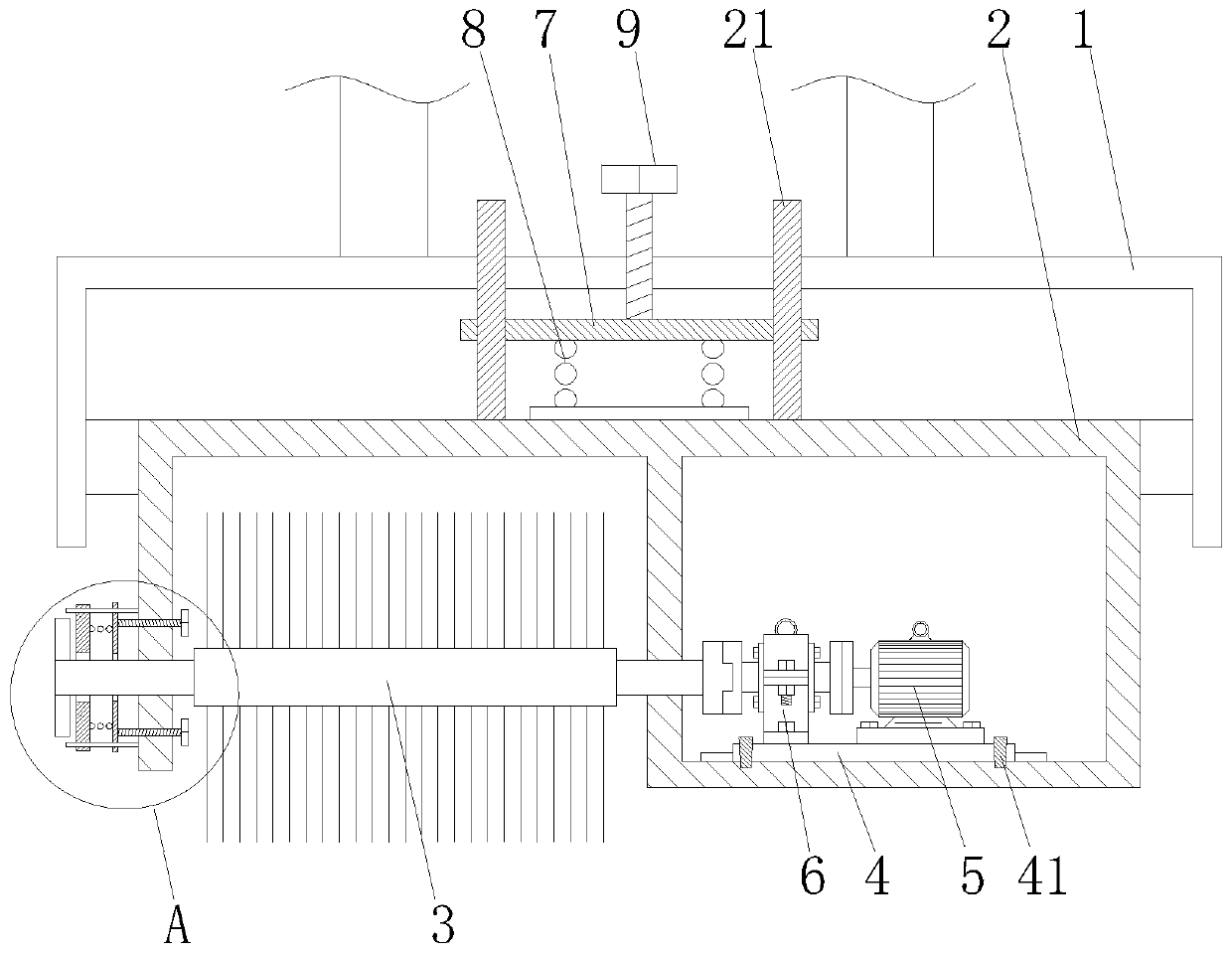

Image

Examples

Embodiment 2

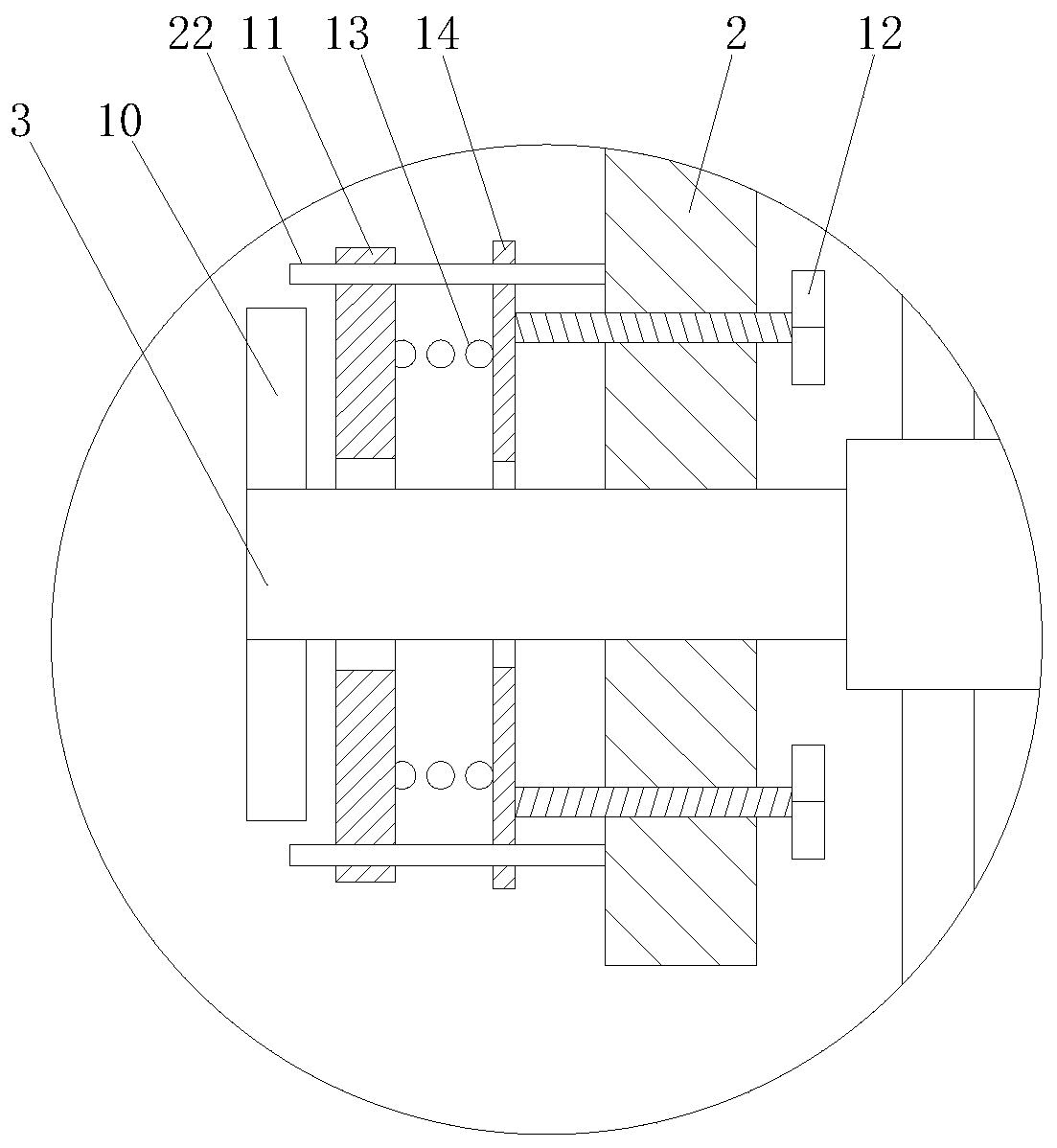

[0029] It differs from Embodiment 1 in that: as figure 2As shown, in this embodiment, a fixed friction disk 10 is installed on the above-mentioned roller shaft 3, and a movable friction disk 11 is slidably connected to the carriage 2. The sliding direction of the movable friction disk 11 is parallel to the axis of the roller shaft 3, At the same time, a compression screw 12 is threadedly connected to the carriage 2 , and the compression screw 12 abuts against the movable friction disc 11 through a compression spring 13 .

[0030] Specifically, the second guide rod 22 is fixed on the carriage 2, and a second guide sleeve (not shown) matching the second guide rod 22 is installed on the movable friction disc 11. The second guide A pressing plate 14 is slidably connected to the rod 22 , the pressing spring 13 is fixedly connected between the movable friction disc 11 and the pressing plate 14 , and the pressing screw 12 is abutted against the pressing plate 14 . That is, the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com