Card chip machining equipment

A technology for processing equipment and chips, used in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., and can solve problems such as temperature rise, insufficient temperature recovery, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

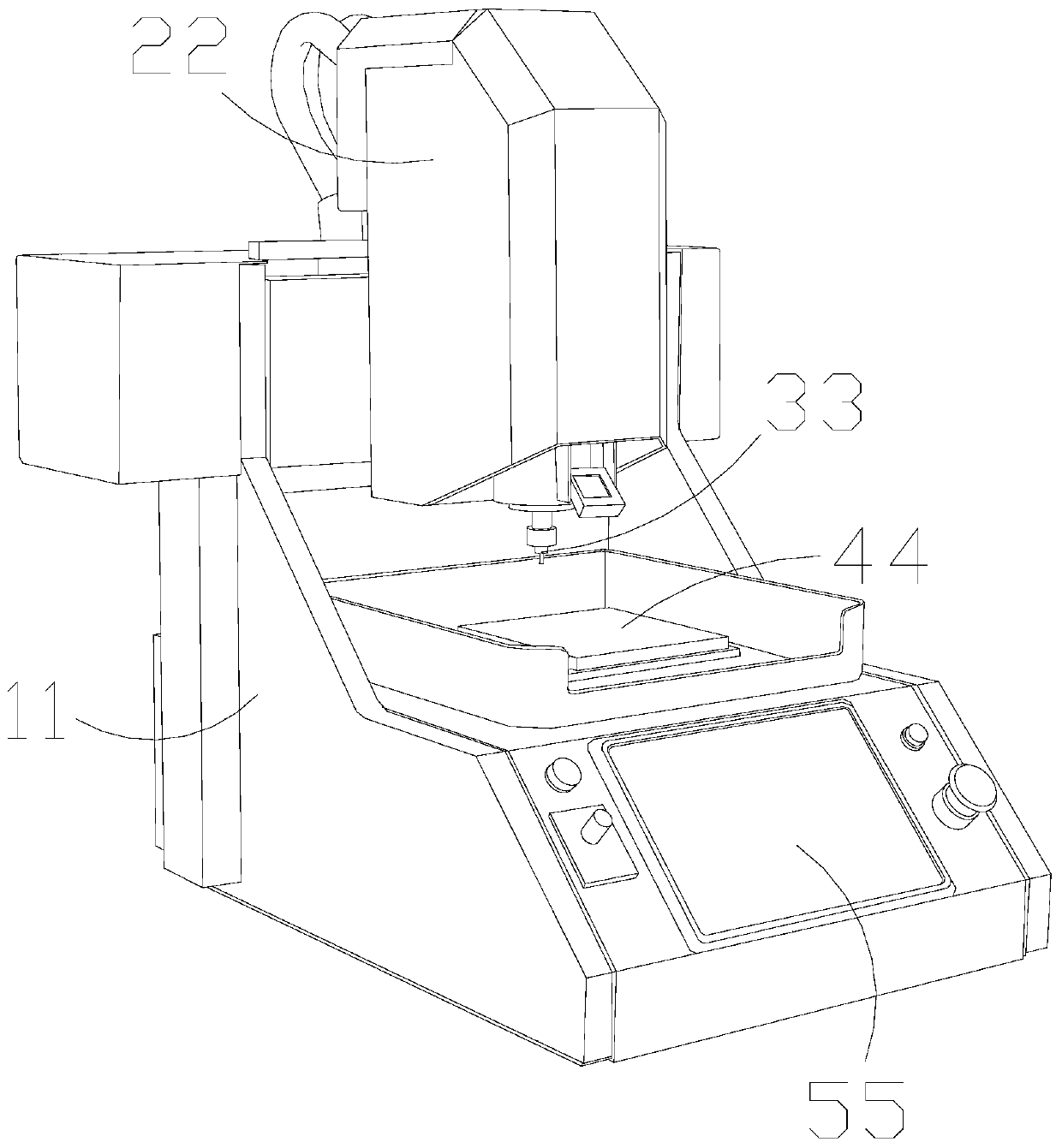

[0031] As attached figure 1 Attached Figure 5 Shown:

[0032] The present invention provides a card chip processing equipment, the structure of which includes a main controller 11, a control head 22, a processing head 33, an operating table 44, and a control panel 55.

[0033] The control panel 55 and the main control machine 11 are an integrated structure, the operation table 44 is welded to the upper surface of the main control machine 11, and the upper end of the processing head 33 penetrates the control head 22.

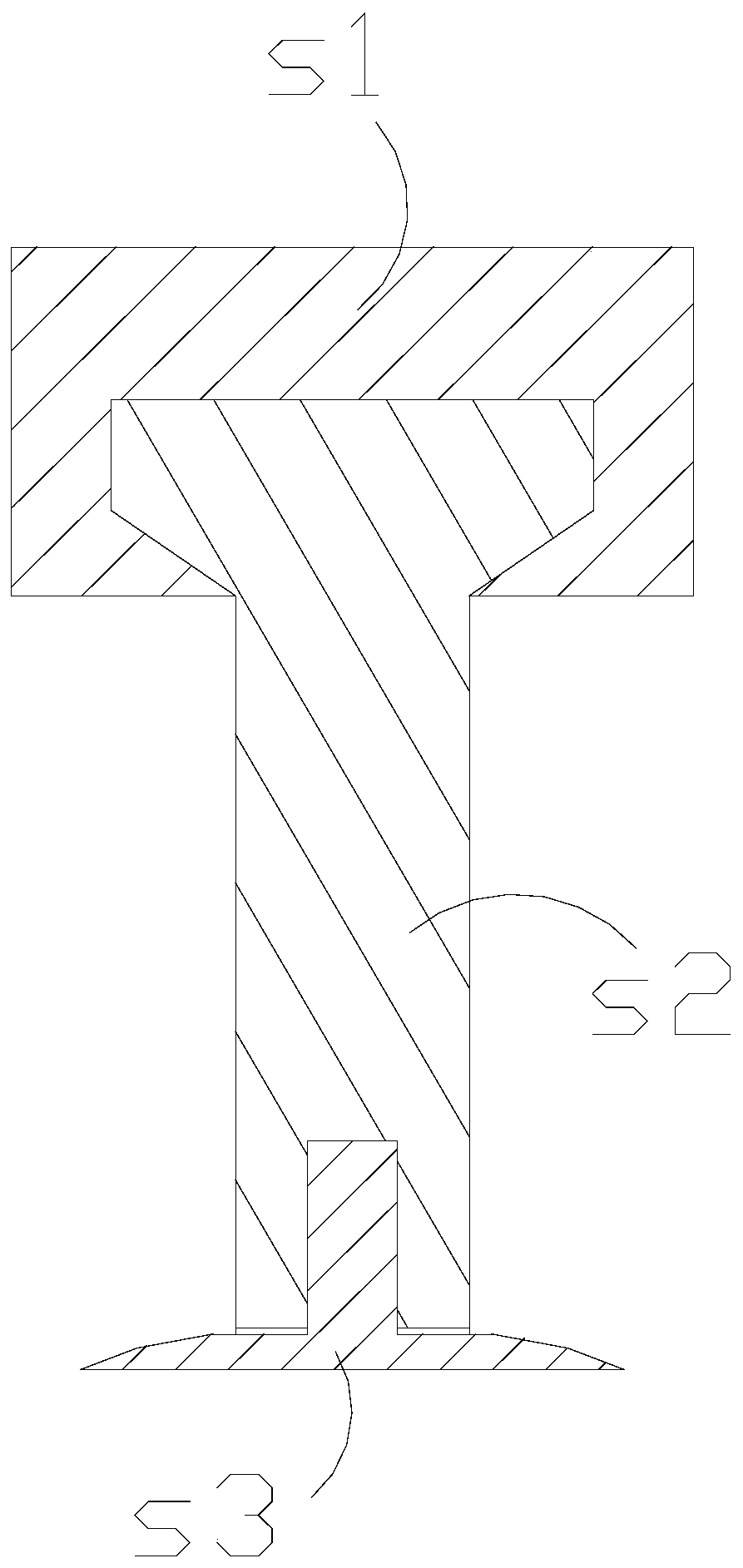

[0034] Wherein, the processing head 33 includes a hub 1, a main rotating rod 2, a bottom bracket 3. The upper end of the main rotating rod 2 is embedded in the hub 1, and a bottom bracket 3 is installed inside the end of the main rotating rod 2 away from the hub 1 , The outer surface of the sleeve head 1 is a square structure, and the inside is in the form of a five-sided inner groove. The sleeve head 1 controls the installation and movable positions of the lower end j...

Embodiment 2

[0041] As attached Image 6 Attached Picture 8 Shown:

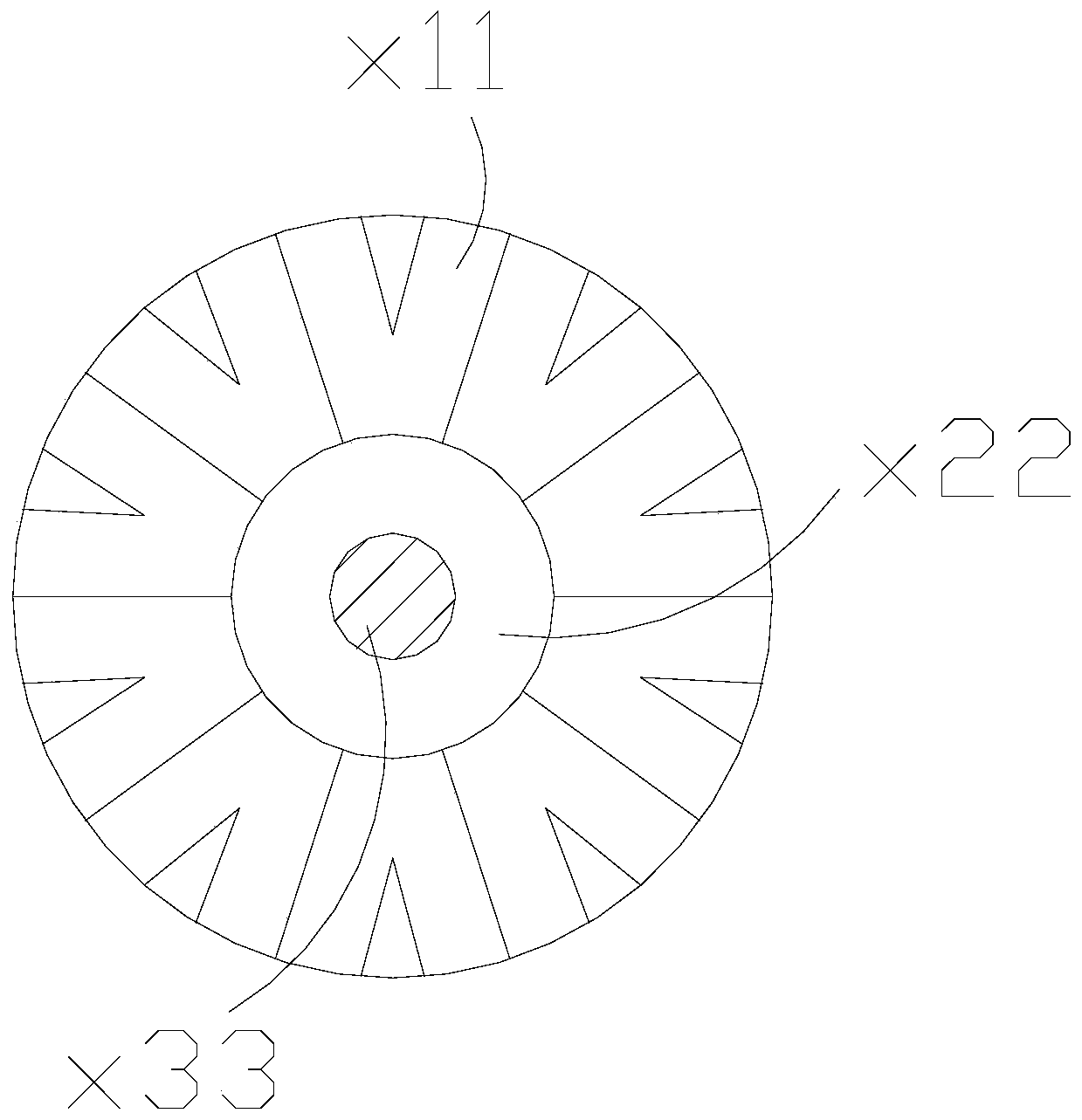

[0042] Wherein, the main rotating rod 2 includes a rotating edging 101 and a medium hard body 202, the rotating edging 101 abuts on the outer surface of the medium hard body 202, the rotating edging 101 has a triangular structure, and the rotating edging 101 It can force external objects as a whole, and when there is a single point of force, the whole line will swing.

[0043] Wherein, the rotating edging 101 includes a total force side 11 and a cohesive angle 22. The total force side 11 is embedded in the cohesive angle 22. There are four cohesive angles 22. The total force side 11 It is a trapezoidal structure. The total force side 11 receives the force at one point as a whole, and the force angle 22 gathers the force at one end to guide it in one direction.

[0044] Wherein, the cohesive angle 22 includes an inner divergence angle 11, a support head 22, and a barrier layer 33. The force barrier layer 33 and the inner diver...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap