Heat and moisture box for antiflaming curtain decorative fabric

A technology of decorative cloth and humid heat box, which is applied in the field of machinery, can solve the problems of complicated external pipelines of the humid heat box, increase in the number of pipelines, and affect stability, and achieve high practical value, improved stability, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

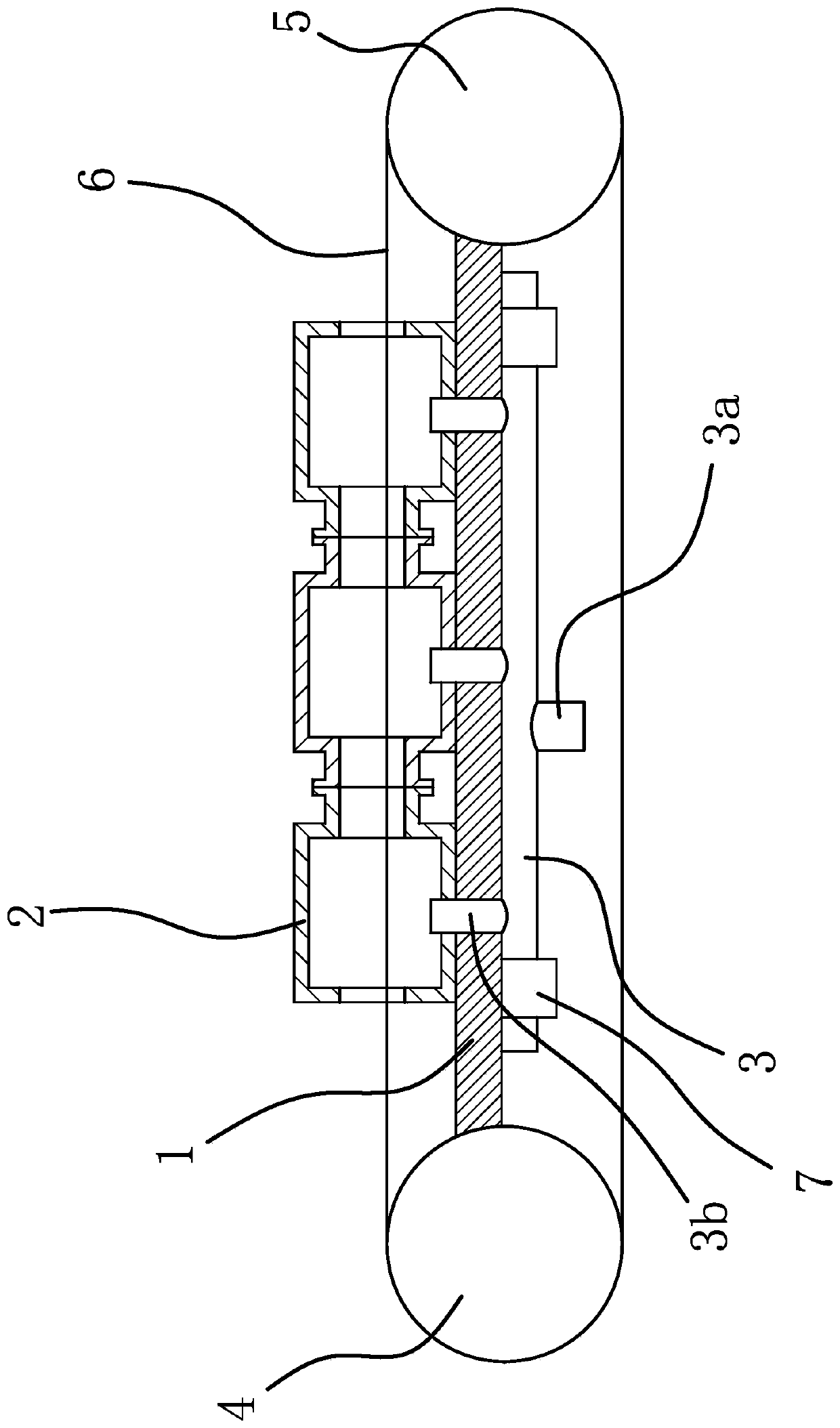

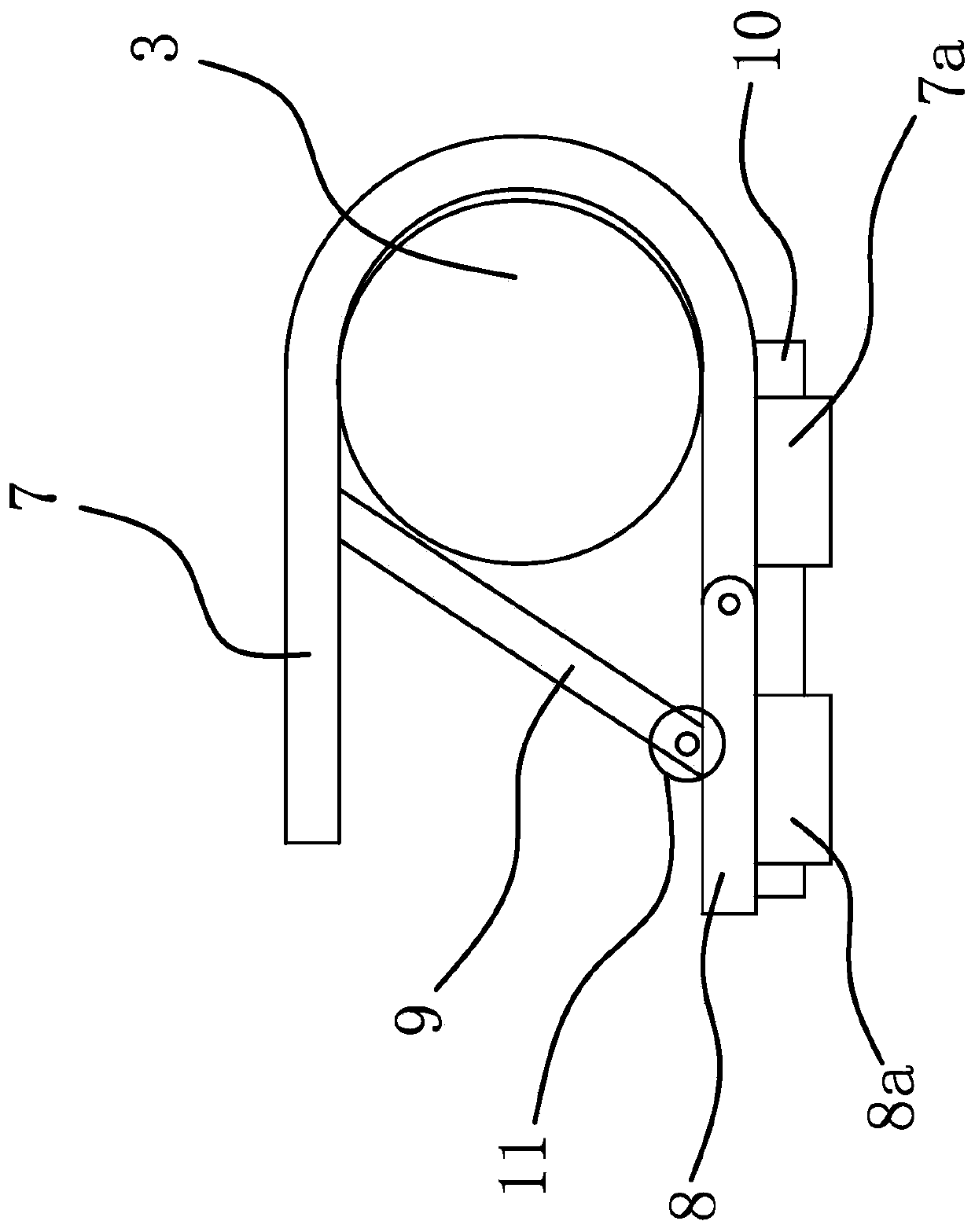

[0031] Such as figure 1 As shown, the humid heat box used for flame-retardant curtain decorative fabrics includes a frame 1, a housing 2, a conveying assembly and a heat pipe 3 for introducing steam. The inside of the housing 2 is a cavity and the number of housings is several The above-mentioned frame 1 is in the shape of a long plate, and several housings 2 are uniformly arranged on the upper part of the frame 1 along the length direction of the frame 1. The heat pipe 3 is fixedly connected to the frame 1. The heat pipe 3 has an inlet 3a and a number of outlets 3b communicating with it. The inlet 3a is used to communicate with the steam heat source. The number of 3b is the same as that of the casings 2 and the positions are arranged in one-to-one correspondence, and the outlet 3b communicates with the inside of the corresponding casing 2 .

[0032] Described conveying assembly comprises driving wheel 4, driven wheel 5 and conveyer belt 6, and above-mentioned driving wheel 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com