Road milling asphalt waste recycling device

A kind of asphalt waste, milling technology, applied in the field of construction waste recycling device, can solve the problems of inconvenient transfer, high transportation cost, poor quality of asphalt mixture, etc., and achieve the effect of improving the quality of regeneration, optimizing the quality of high-quality products, and reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

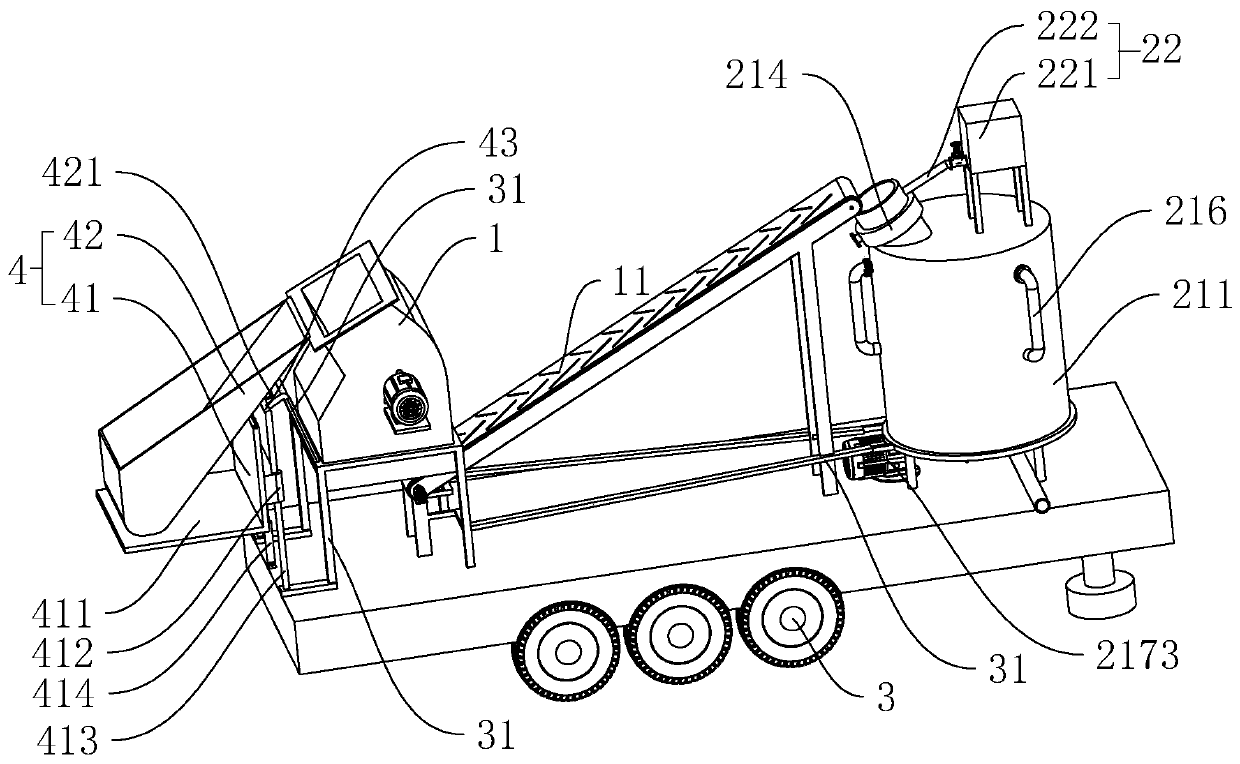

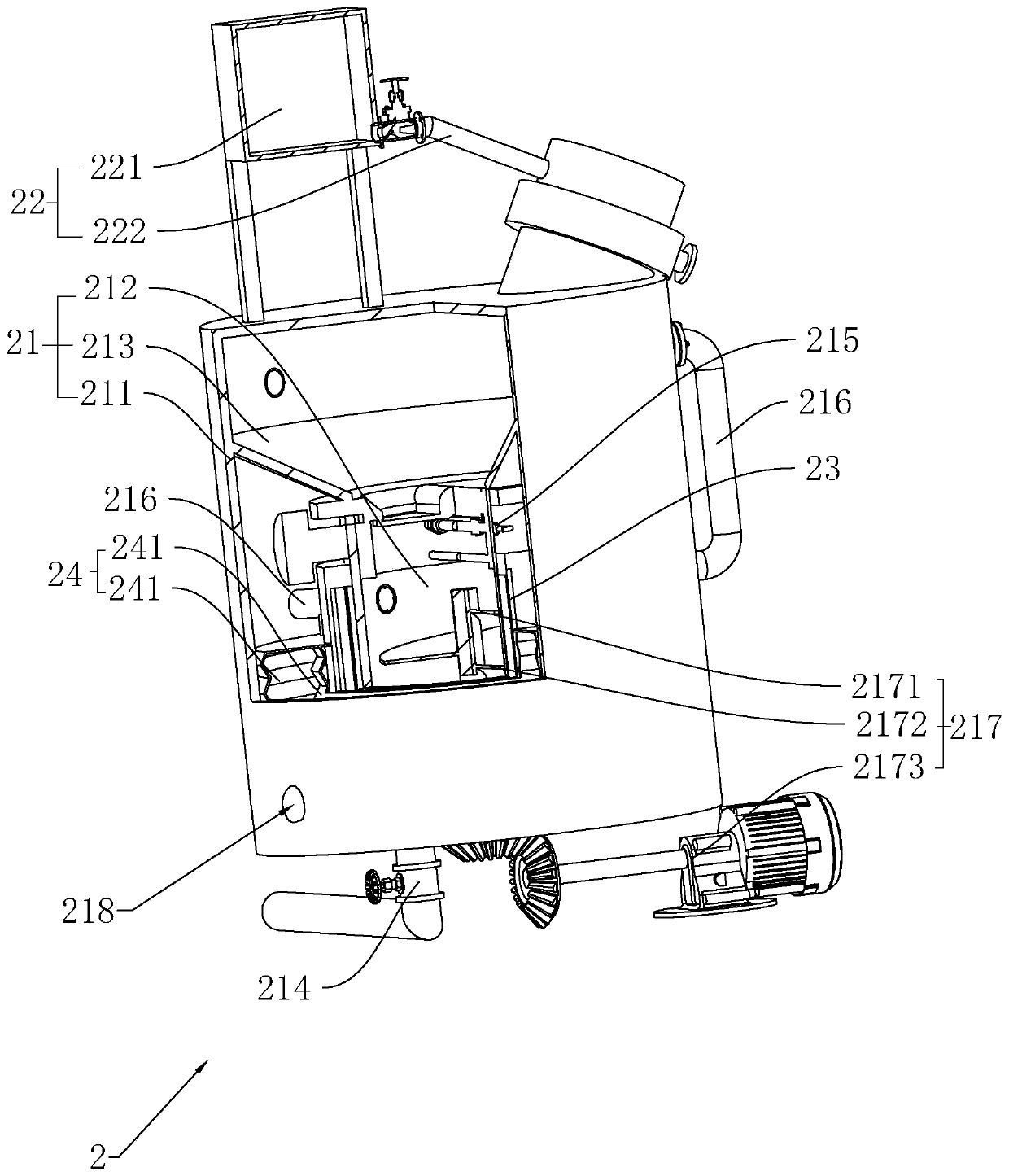

[0034] refer to figure 1 and figure 2 , is a road milling asphalt waste recycling device disclosed in the present invention, comprising a crusher 1 for crushing asphalt concrete waste, a mixing mechanism 2 and a running mechanism 3 for regenerating the crushed asphalt concrete waste. Among them, the running mechanism 3 is a low-slab semi-trailer compartment, and the crusher 1 and the mixing mechanism 2 are fixedly connected to the upper surface of the running mechanism 3, so that when in use, the running mechanism 3 only needs to be parked at the construction site by a trailer. It only needs to be nearby, and there is no need to occupy additional equipment during the construction process. At the same time, it is convenient to transfer the equipment to a closer construction site when the construction site is changed. Wherein, the crusher 1 may be a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com