A Quick Locking Mechanism for the Sliding Form of Multiple Conjoined Thin-wall Silo

A locking mechanism and thin-walled cylinder technology, applied in building construction, formwork/template/work frame, on-site preparation of building components, etc., can solve inconvenient operation, leakage of auxiliary positioning parts, and many processes problem, to achieve the effect of convenient operation and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

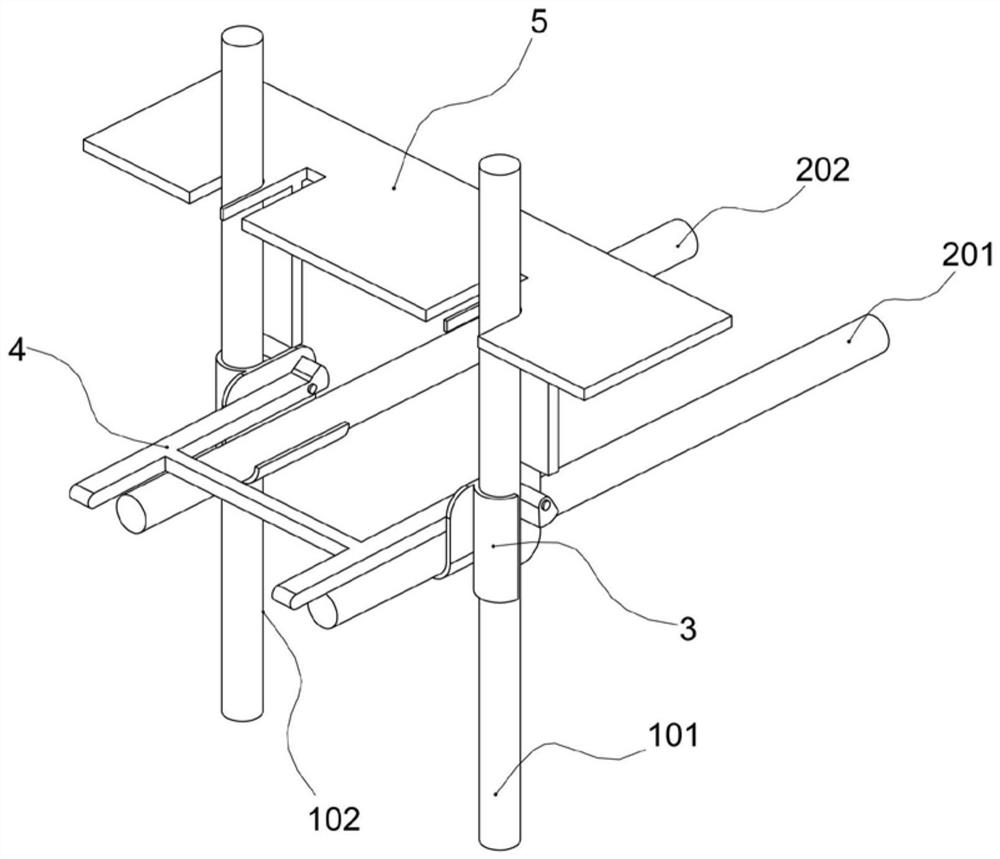

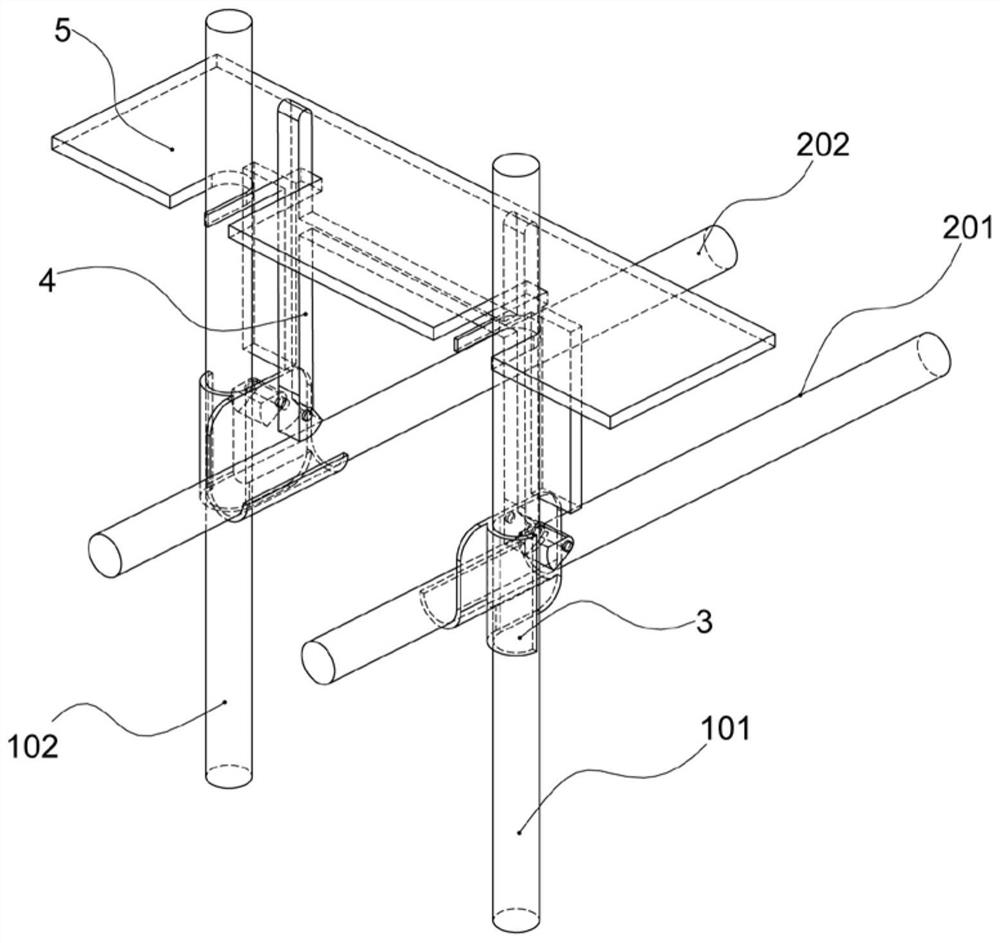

[0026] Such as figure 1 As shown, a fast locking mechanism for a sliding form of a multi-joint thin-walled silo includes two double-joint buckle seats 3 , a locking handle 4 and a positioning platen 5 .

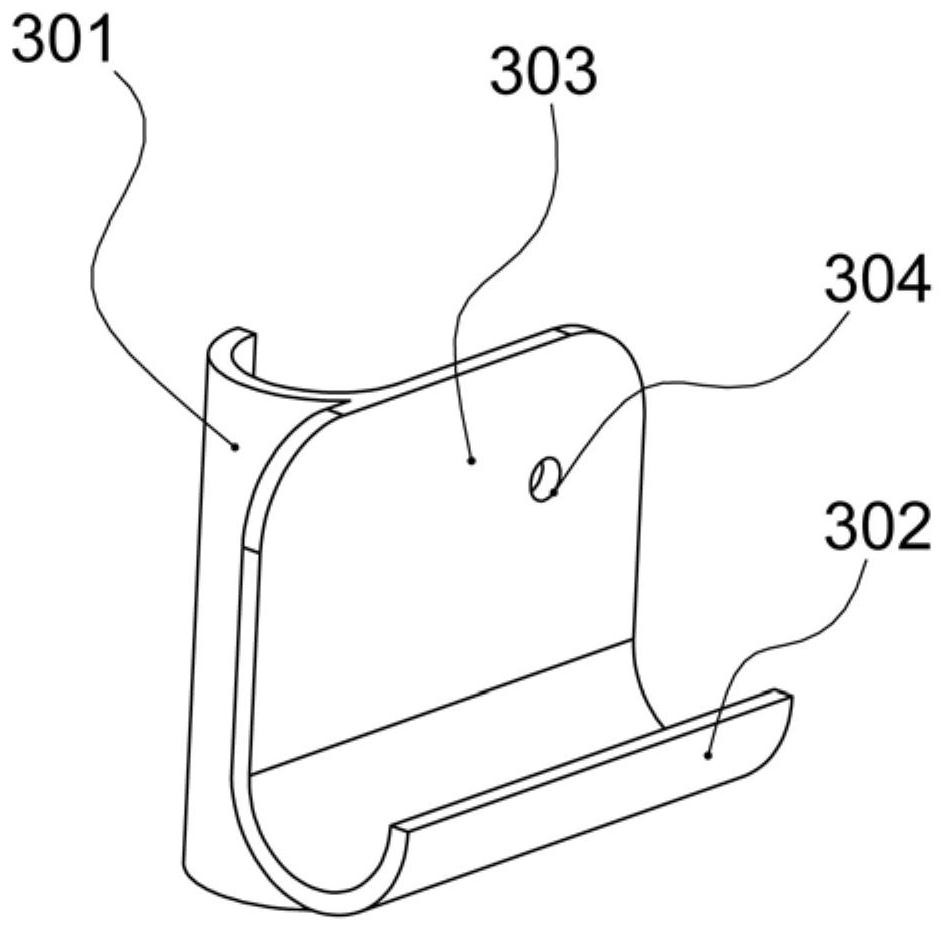

[0027] Such as image 3 As shown, the double buckle seat 3 includes a base plate 303, and the two sides of the base plate 303 are respectively provided with a longitudinal positioning groove 301 and a transverse positioning groove 302. The longitudinal positioning groove 301 is perpendicular to the axis of the transverse positioning groove 302. A hinged hole is provided for assembly with a locking handle.

[0028] Such as Figure 4 As shown, the locking handle 4 includes at least one transverse rib 401, and two swing bars are vertically arranged on both sides of the transverse bar, that is, a first swing bar 402 and a second swing bar 403, and the lower end of the first swing bar 402 is arranged The third locking cam 406, the fourth locking cam 407 is provided at the lower...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap