Clamping device for rail butt welding

A technology for clamping devices and rails, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing the force of the clamping cylinder 4, increasing the weight or height of the whole machine, etc., to ensure vertical positioning, reduce the Effect of wear and simplification of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

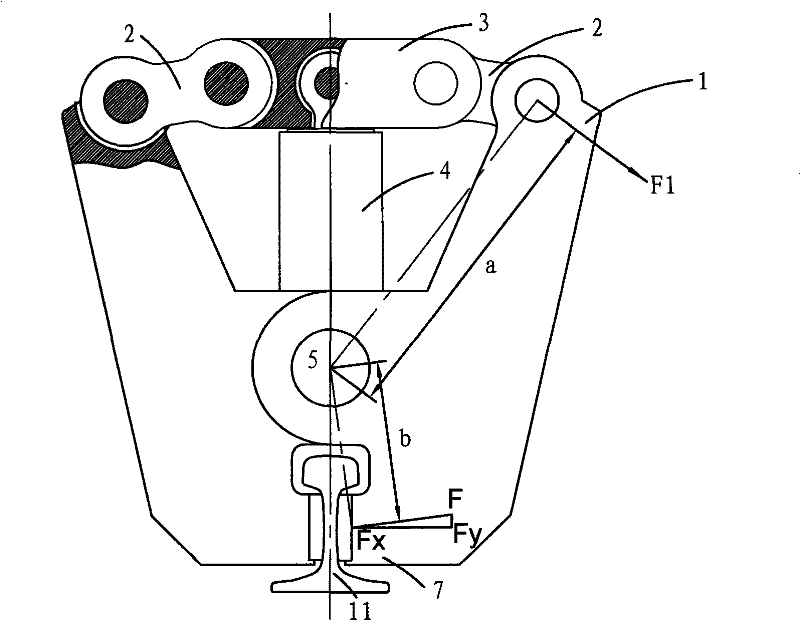

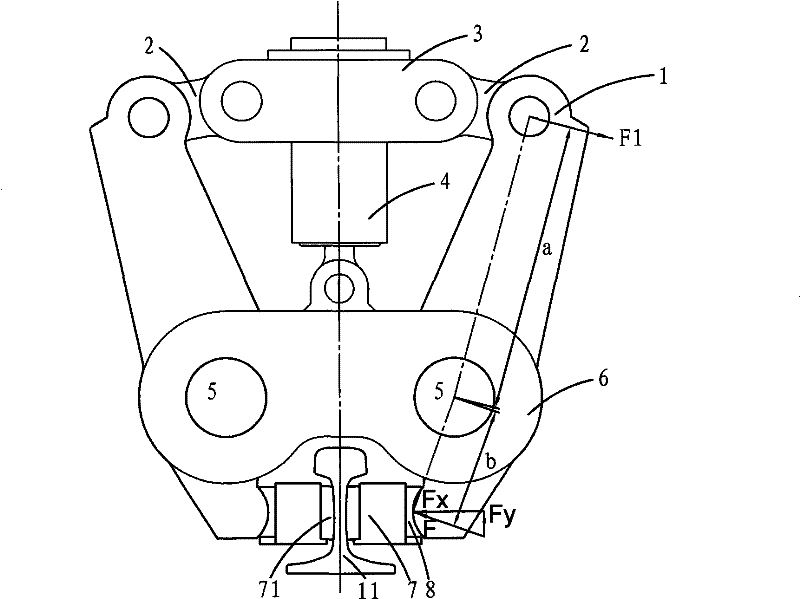

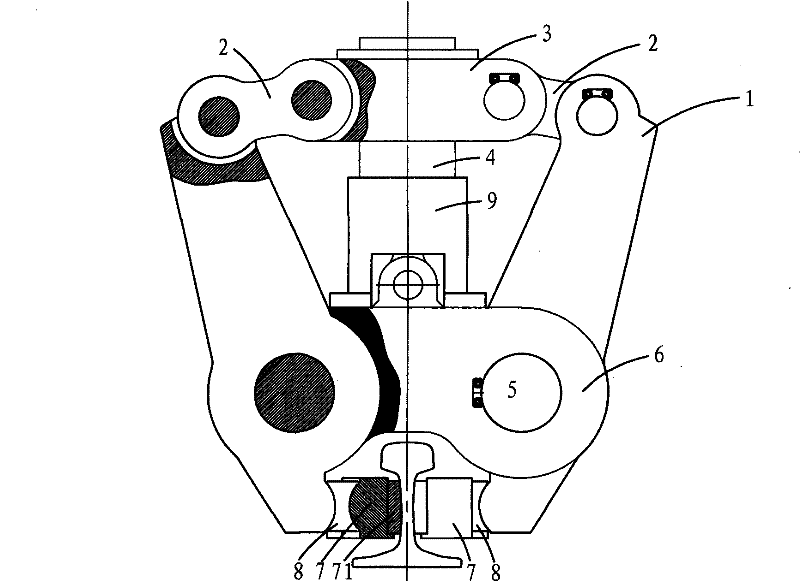

[0033] Embodiment 1: as figure 2 , image 3 , Figure 4 and Figure 5 As shown, on the basis of the prior art, the single-axis rotation structure of the jaws in the prior art is improved to a double-axis rotation structure of the jaws, so that the center of the rotation axis is lowered, and a higher clamping force magnification is obtained. ; Simultaneously, since the center of rotation is respectively located on both sides of the rail, the clamps apply a horizontal clamping force and a vertical upward lifting force to the rail at the same time, so there is no need to set up a rail lifting mechanism, thereby simplifying the structure. The specific scheme is: a clamping device for rail butt welding, including two pairs of clamps 1, clamping jaws 7, a clamp applying mechanism, and two rotating shafts 5; the clamp applying mechanism includes connecting rods 2 , Clamping oil cylinder support 3 and clamping oil cylinder 4, clamping oil cylinder 4 is installed vertically, its tw...

Embodiment 2

[0038] Embodiment 2: as Figure 9 and 10 As shown, the main difference between Embodiment 2 and Embodiment 1 lies in the difference of the clamp applying mechanism. The clamp applying mechanism in this embodiment includes a transverse connecting rod 21, clamping oil cylinder transverse supports 31, 32 and clamping Oil cylinder 4, the clamping oil cylinder 4 is installed horizontally, and its two ends are respectively connected with clamping oil cylinder transverse supports 31, 32, and the upper end of the clamp 1 is connected with the clamping oil cylinder transverse supports 31, 32 through transverse connecting rod 21 32 active connections.

Embodiment 3

[0039] Embodiment 3: as Figure 11 As shown, the main difference between Embodiment 3 and Embodiment 1 lies in the difference of the clamp force applying mechanism. The clamp force applying mechanism in this embodiment includes a clamping oil cylinder 4, which is installed horizontally, and its two ends are respectively There is a hinge seat, and the upper end of the jaw 1 is directly connected to the hinge seats at both ends of the clamping cylinder 4 movably.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap