Memory alloy locking and releasing mechanism

A memory alloy, locking and releasing technology, used in mechanical equipment, fixing devices, etc., can solve the problems of limited movement range of the locked mechanism, poor consistency of locking or releasing state, no degree of freedom, etc., to reduce impact The effect of reducing the batch size error of parts and meeting the requirements of environmental cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

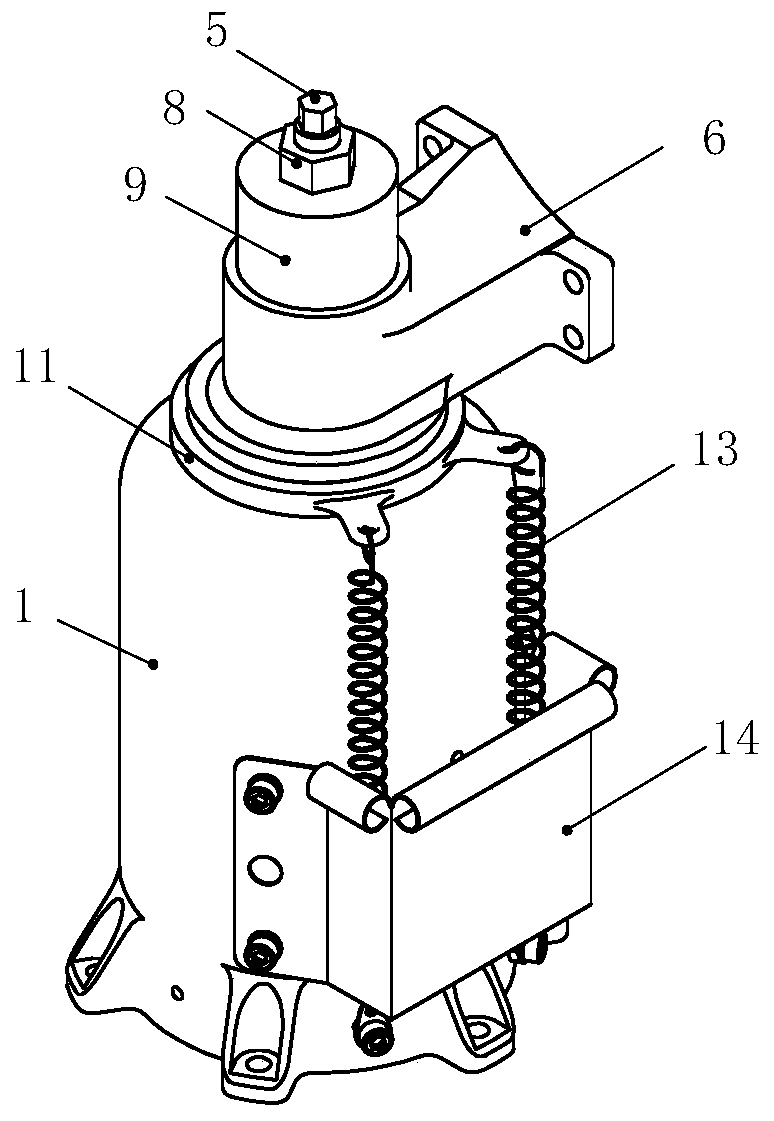

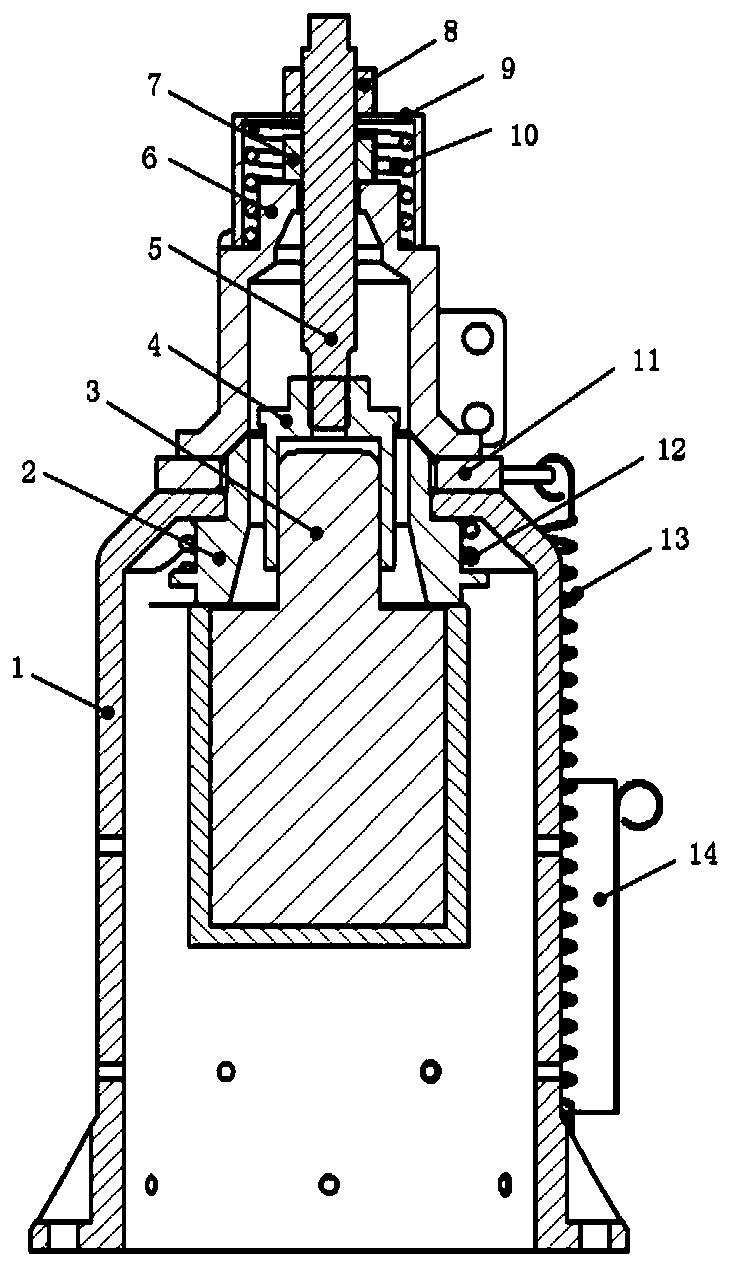

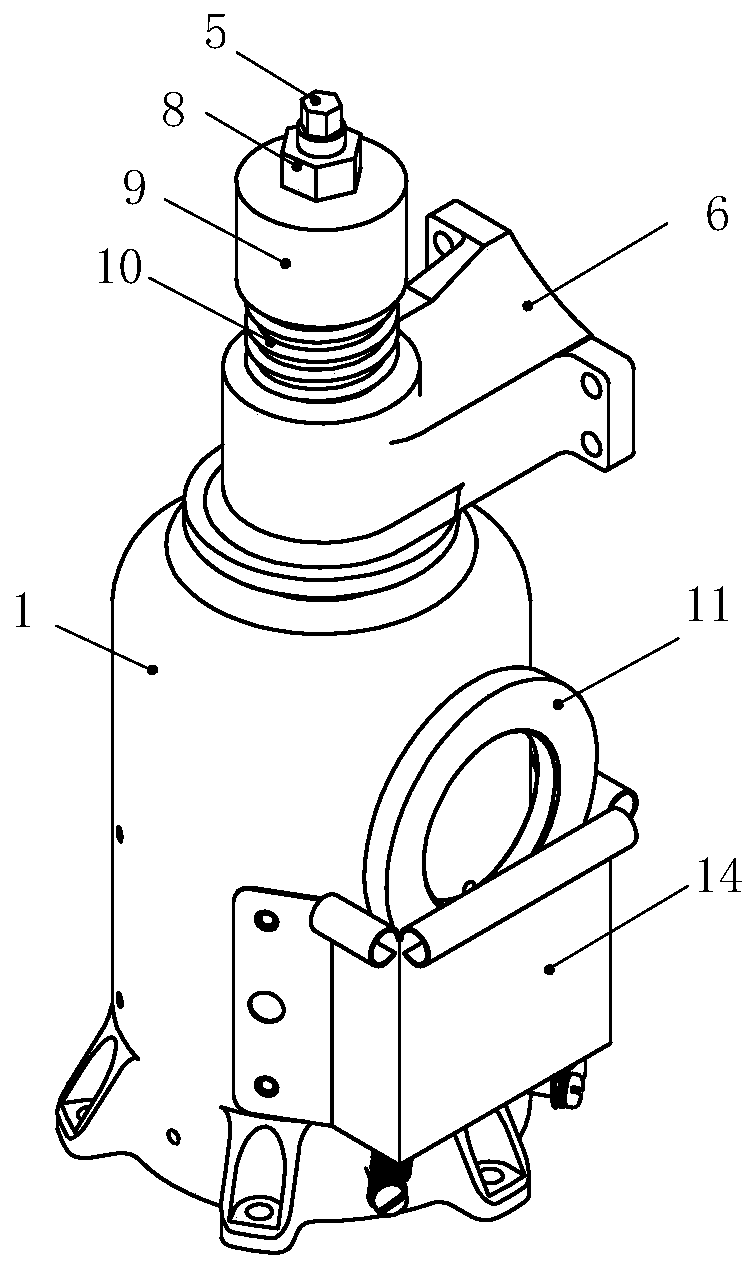

[0036] like Figures 1 to 6 As shown, a memory alloy locking and releasing mechanism includes a locking seat 1, a pressing cone 2, a memory alloy unlocking device 3, a separating cap 4, a locking rod 5, a locking arm 6, a locking nut 7, an anti-disconnection Nut 8 , anti-drop cap 9 , anti-drop spring 10 , separation pad 11 , separation spring 12 , tension spring 13 , storage cover 14 .

[0037] The locking seat 1 is a shell with through holes at both ends, one end of the shell is provided with through holes for passing through the compression cone 2, the memory alloy unlocker 3, and the separation spring 12, and also has a flange for installation and fixation. , the other end of the casing has a shoulder for passing through and installing the pressing cone, the outer surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com