Processing method for deformation of rotary frame of circular cooler

A technology of rotary frame and treatment method, which is applied in the direction of processing discharged materials, furnaces, lighting and heating equipment, etc., and can solve problems such as deformation of the rotary frame of the ring cooler, reduce equipment accidents, simplify the processing method, and increase the contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

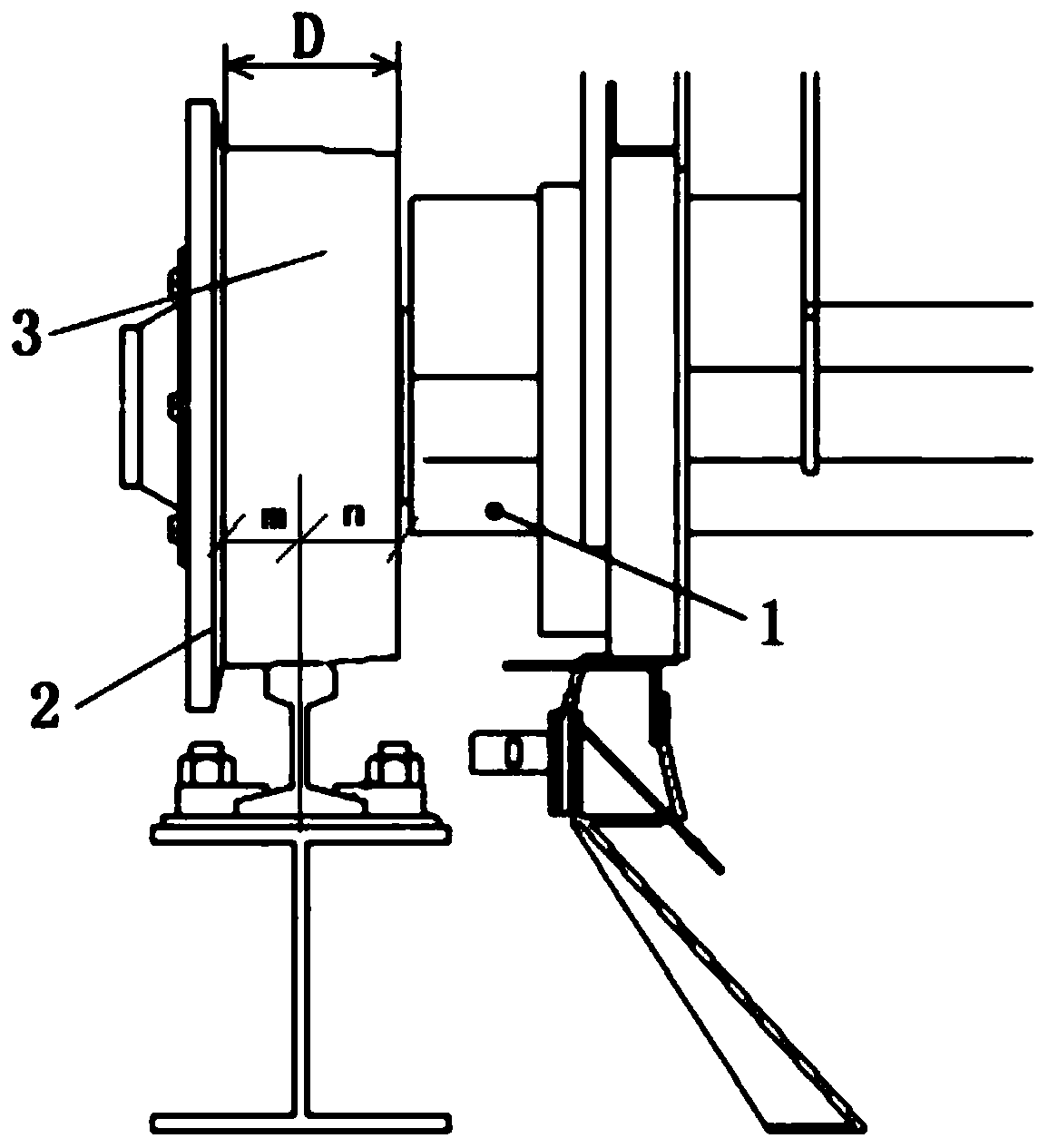

[0021] If the rotary frame 7 of the annular cooler is deformed into an ellipse or pear shape, the wheel of the trolley 1 that is far away from the center of the original annular cooler after deformation is replaced with the wheel 2 of the trolley with a large tread 3. Specifically, when other dimensions remain unchanged Next, the size of the platform wheel on the outer side of the ring cooling is increased by n, and the size of m is unchanged; the size of the platform wheel on the inner side of the ring cooling is increased by m, and the size of n is unchanged; to ensure that the radius of the rotary frame 7 becomes larger and the back car 1 is normal operation, and can take into account the interchangeability of the original platform wheel 2.

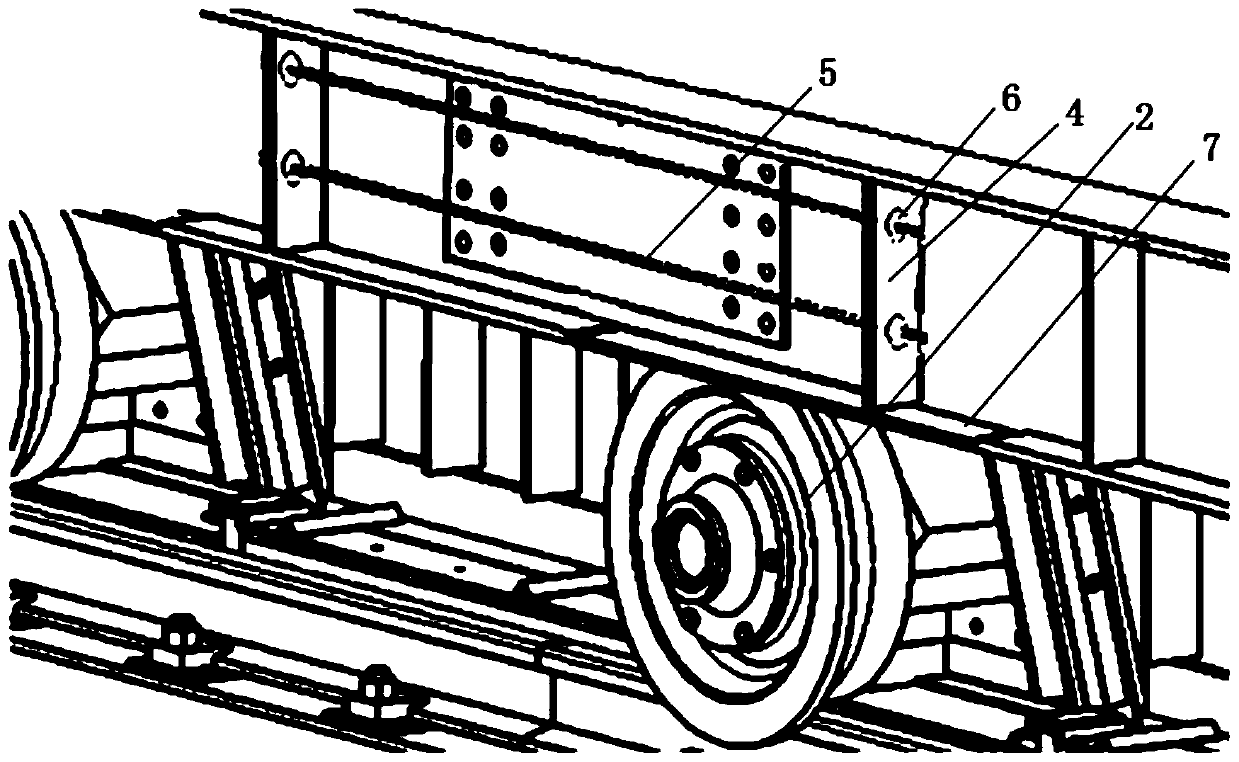

[0022] Install the pull rod device at the position of the rotary frame 7 with the largest deformation, adjust the position of the nut 6, continuously adjust the tension of the screw rod 5, and gradually restore the roundness of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com