Fire combustion and ventilation control system for spiral tunnel group

A technology of ventilation control system and tunnel group, applied in the field of tunnel ventilation and smoke exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

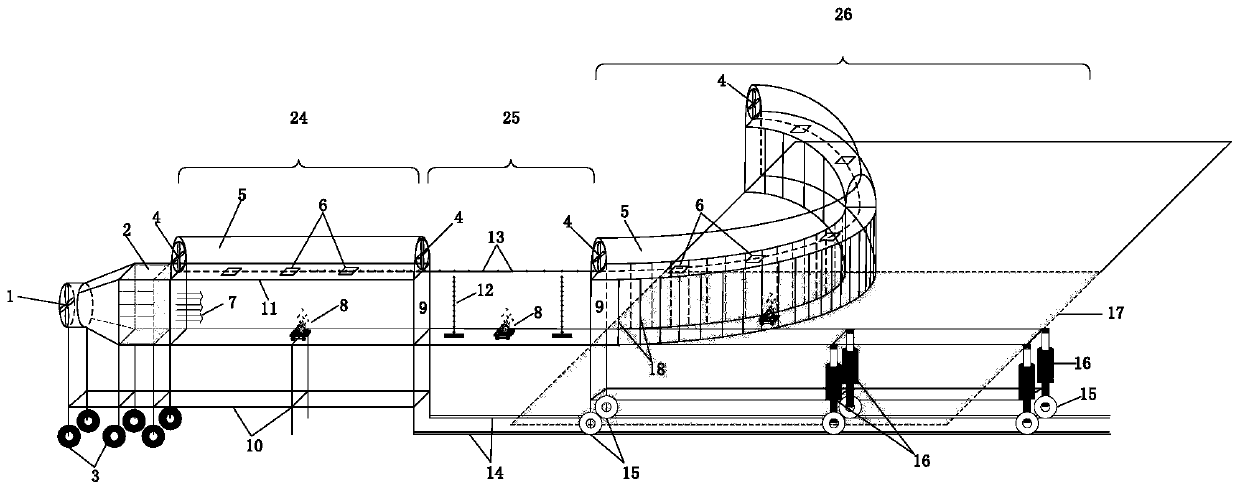

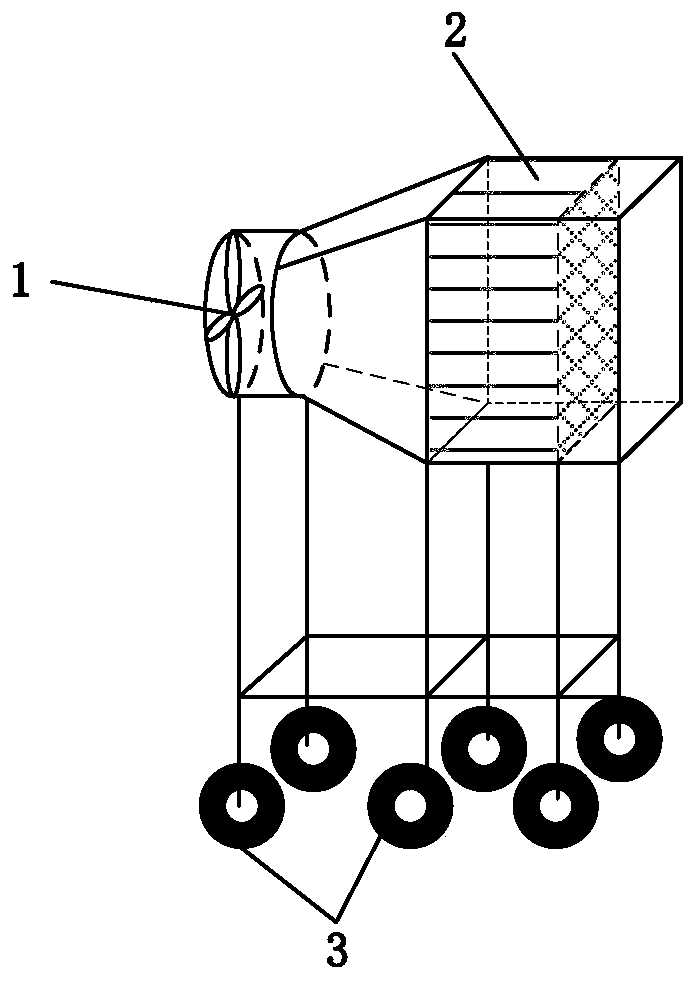

[0051] Specific Example 1: Carry out experimental research on flue gas channeling in a group of spiral tunnels.

[0052] For the spiral tunnel group, whether the smoke can spread from one tunnel to the adjacent tunnel mainly depends on the longitudinal wind of the tunnel, the heat release rate of the fire source, the aspect ratio of the tunnel, the slope and the distance between the tunnel groups. spacing, and the size of the tunnel curve radius, etc. Based on the theoretical analysis of the Froude number, the Froude number represents the relative competition between the inertial force formed by the longitudinal wind in the tunnel and the thermal buoyancy of the fire source. In the experiment, the control variable method was used to carry out multiple sets of simulation experiments, and the experimental results of the flue gas channeling from one tunnel to the other in the spiral tunnel group were obtained. The channeling of the flue gas needs to be determined by the laser she...

specific Embodiment 2

[0053] Specific Example 2: Carry out experimental research on flue gas control of spiral tunnel groups.

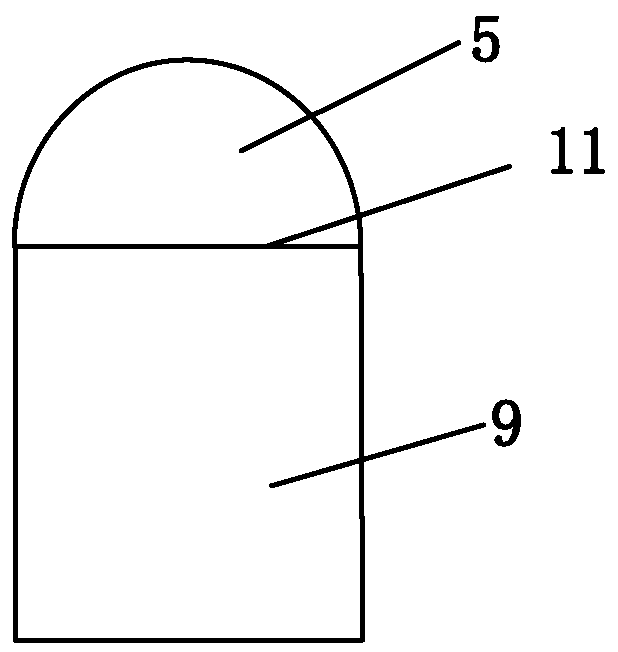

[0054] Due to the existence of the slope of the spiral tunnel, there will be a chimney effect; at the same time, due to the existence of the spiral, the flue gas will also produce a curved motion. This poses a challenge for smoke control in tunnel fires. In view of the experimental research on smoke control of spiral tunnel groups, it is planned to carry out comparative research on working conditions of tunnel groups with different slopes and curvature radii, different longitudinal wind sizes, fire source power and distance between tunnel groups, and summarize the smoke control schemes under different conditions. Such as critical wind speed evolution model, smoke stratification stability determination criteria, etc. At the same time, guide the evacuation route correctly to minimize the impact of fire smoke on the evacuation of personnel and property.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com