Compressed air supply installation for operating pneumatic installation, method and vehicle

A technology of compressed air and facilities, applied in the direction of vehicle springs, vehicle parts, transportation and packaging, etc., to achieve the effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

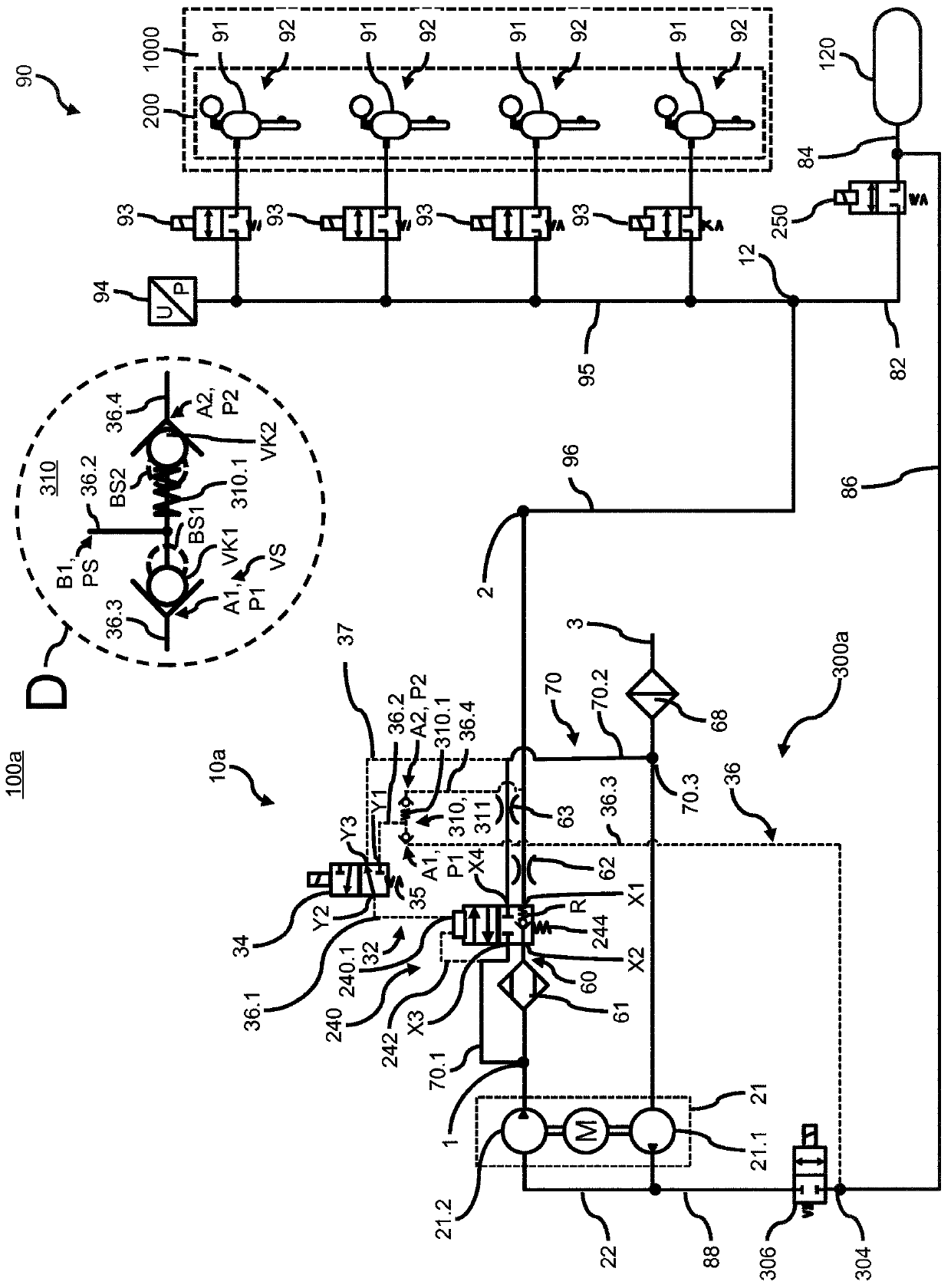

[0037] figure 1 A preferred embodiment of a pneumatic system 100a is shown with a compressed air supply system 10a and an air spring system 90 for the symbolically shown vehicle suspension of a vehicle 1000 not shown in detail. The compressed air supply system 10 a has a compressed air supply 1 , a compressed air connection 2 leading to the air spring system 90 and a vent connection 3 leading to the surrounding environment. Furthermore, the compressed air supply installation 10 a also includes a pneumatic main line 60 between the compressed air supply 1 and the compressed air connection 2 .

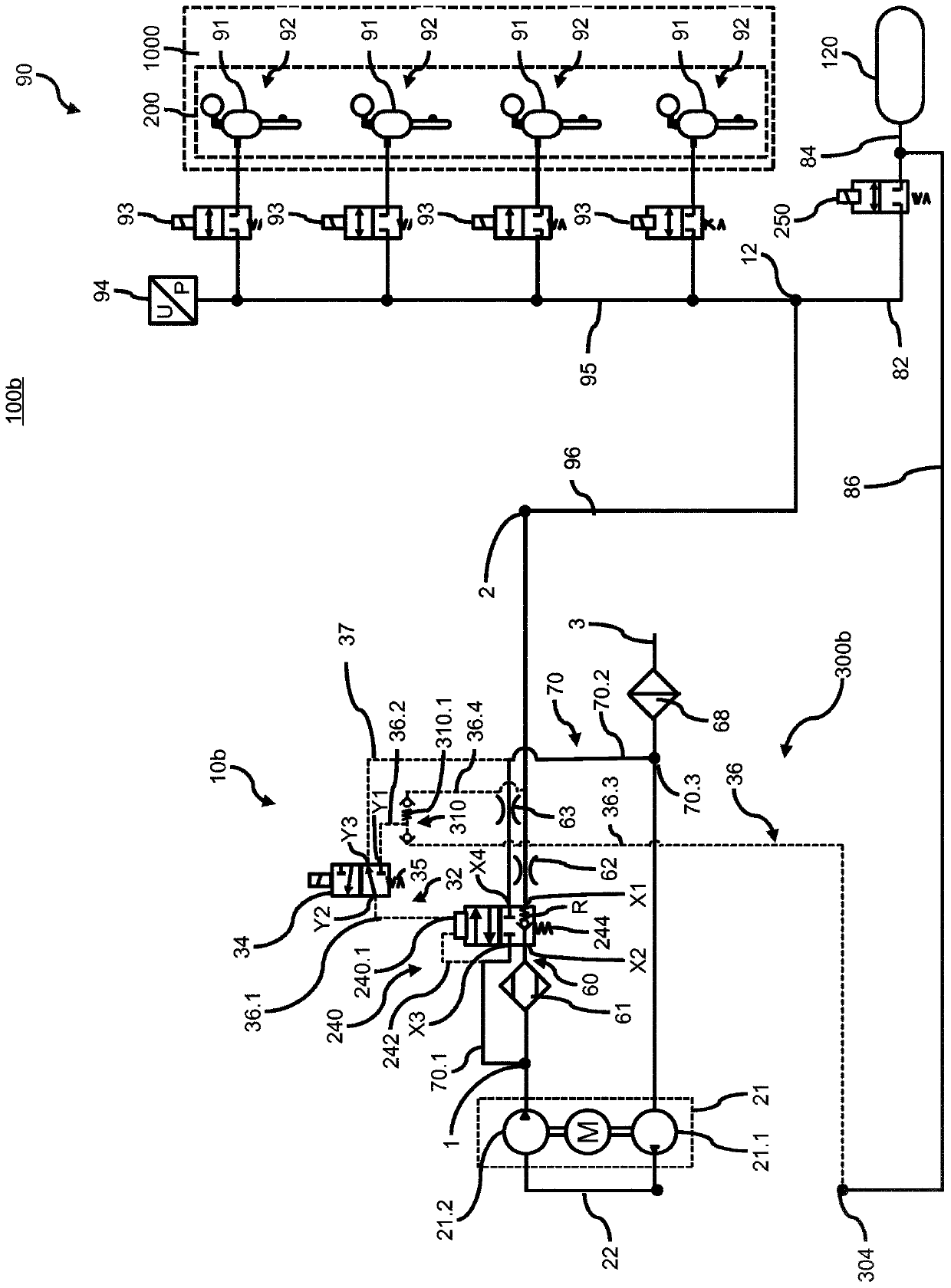

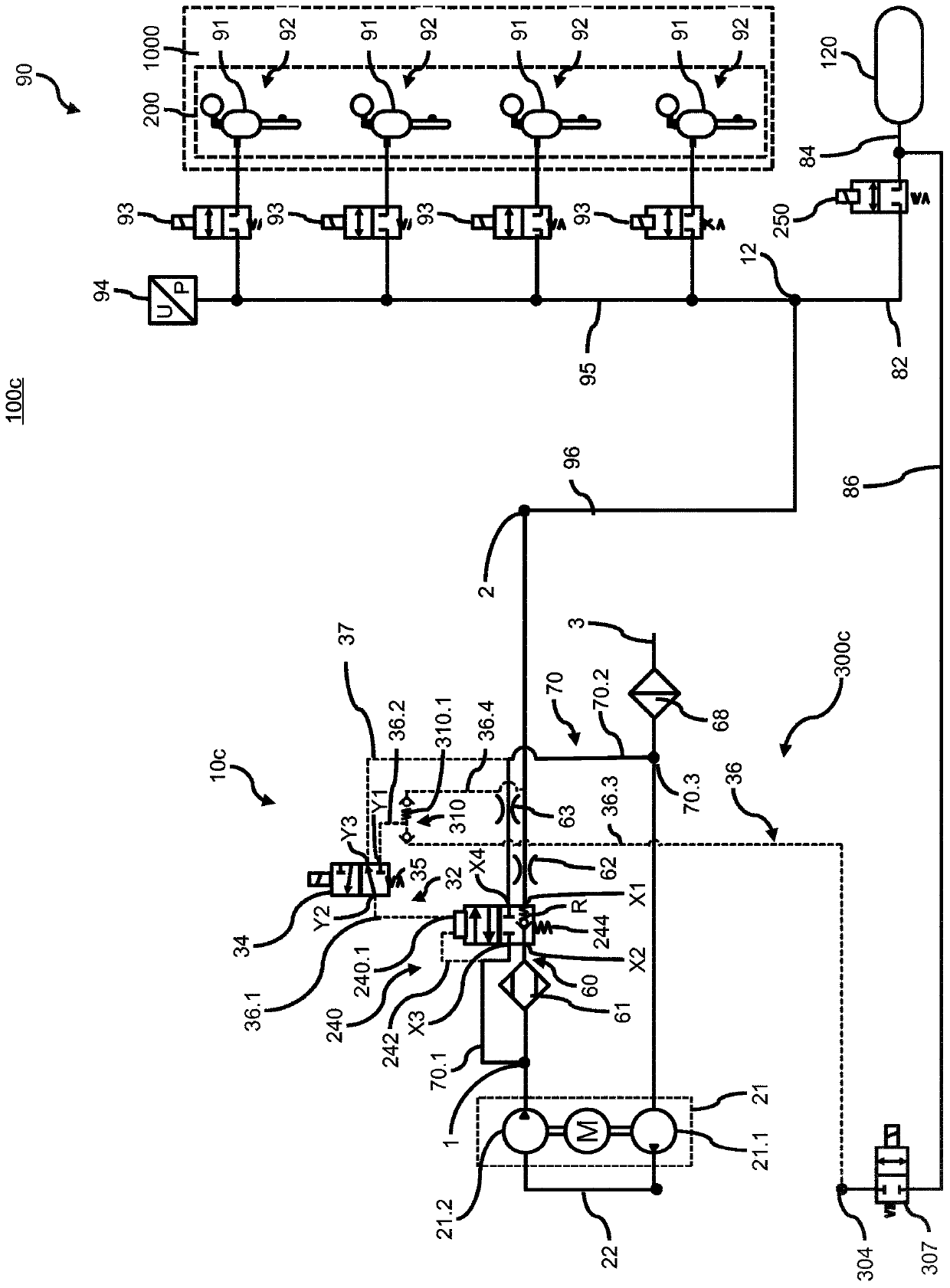

[0038] This and the principle instructions described below for constructing a pneumatic system with compressed air supply system 10 a and pneumatic system 90 also apply to Figures 1 to 3 A variant of a pneumatic system 100 a , 100 b , 100 c with a corresponding compressed air supply 10 a , 10 b , 10 c is shown. For the sake of simplicity, it is meaningful and expedient to use the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com