Automatic helicopter cleaning device

An automatic cleaning and cleaning device technology, applied in aircraft cleaning, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve fast cleaning performance, ensure safety, and solve the effects of excessive fresh water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

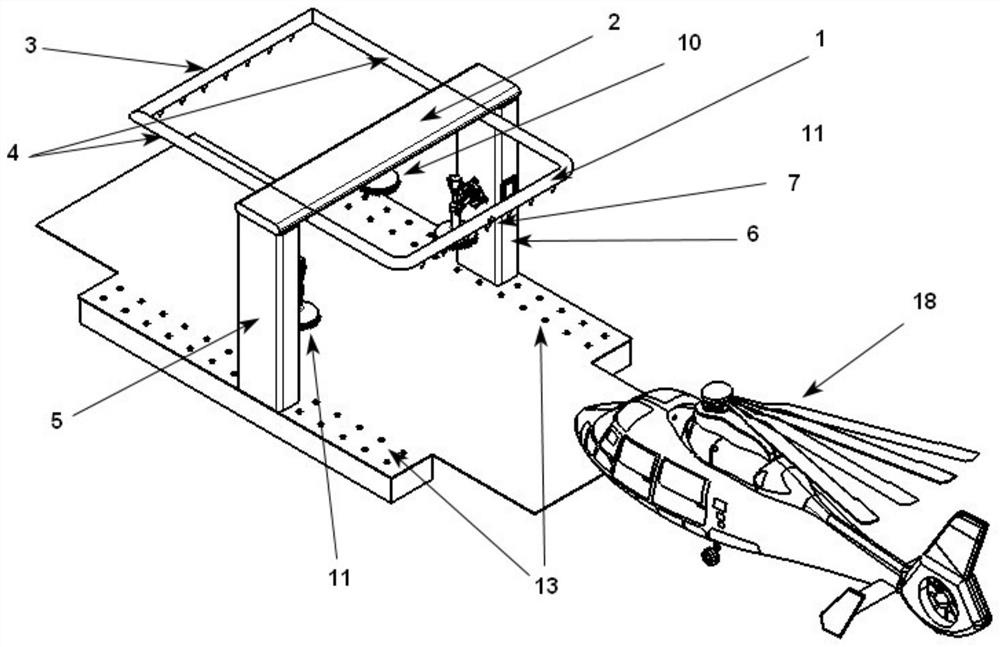

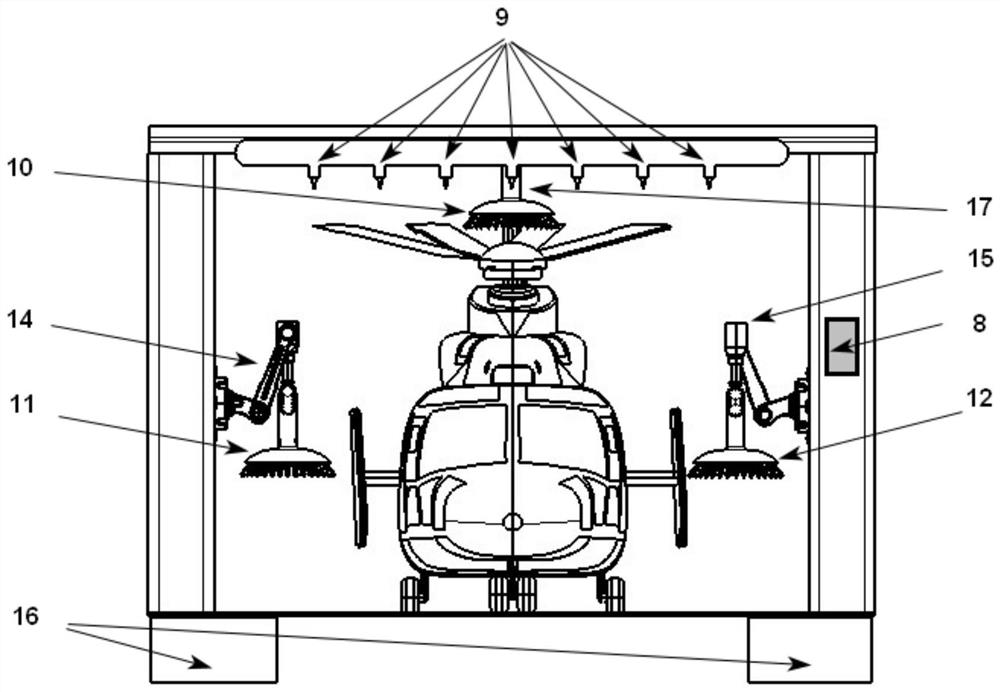

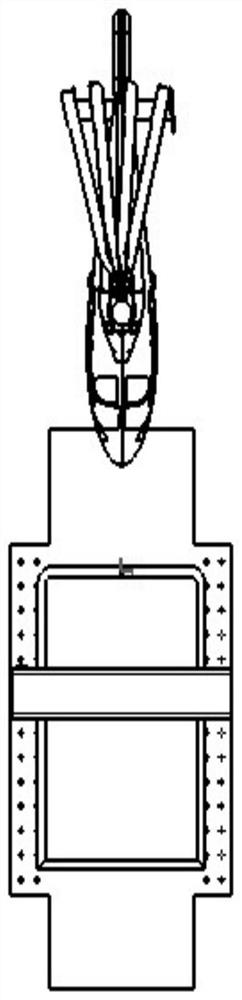

[0029] In this embodiment, the helicopter automatic cleaning device mainly includes the first beam 1, the second beam 2, the third beam 3, the support frame 4, the left column 5, the right column 6, the infrared camera 7, the manual operation panel 8, the Nozzle 9, top cleaning brush 10, left cleaning brush 11, right cleaning brush 12, stainless steel partition 13, left mechanical arm 14, right mechanical arm 15, circulating water tank 16 and top telescopic rod 17.

[0030] The insides of the left cleaning brush 11 , the right cleaning brush 12 and the top cleaning brush 10 are all provided with pressure sensors.

[0031] When the present invention is in use, the helicopter 18 is first pulled in the hangar along the marking line by the traction device, and when approaching the right column 6, the infrared camera 7 on the right column 6 takes pictures of the helicopter 18, and transmits the image data to the manual operation panel 8 to identify the model. After the model is rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com