Preparation method of high-water-solubility fructus cannabis extract

A technology of hemp seed and extract is applied in the field of preparation of highly water-soluble hemp seed extract, and can solve the problems of high content of unsaturated fatty acid components, affecting the quality of hemp seed oil, restricting the application of hemp seed oil, and the like, Achieve the effect of enhancing physiological function, preventing cardiovascular and cerebrovascular diseases, and protecting eyesight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

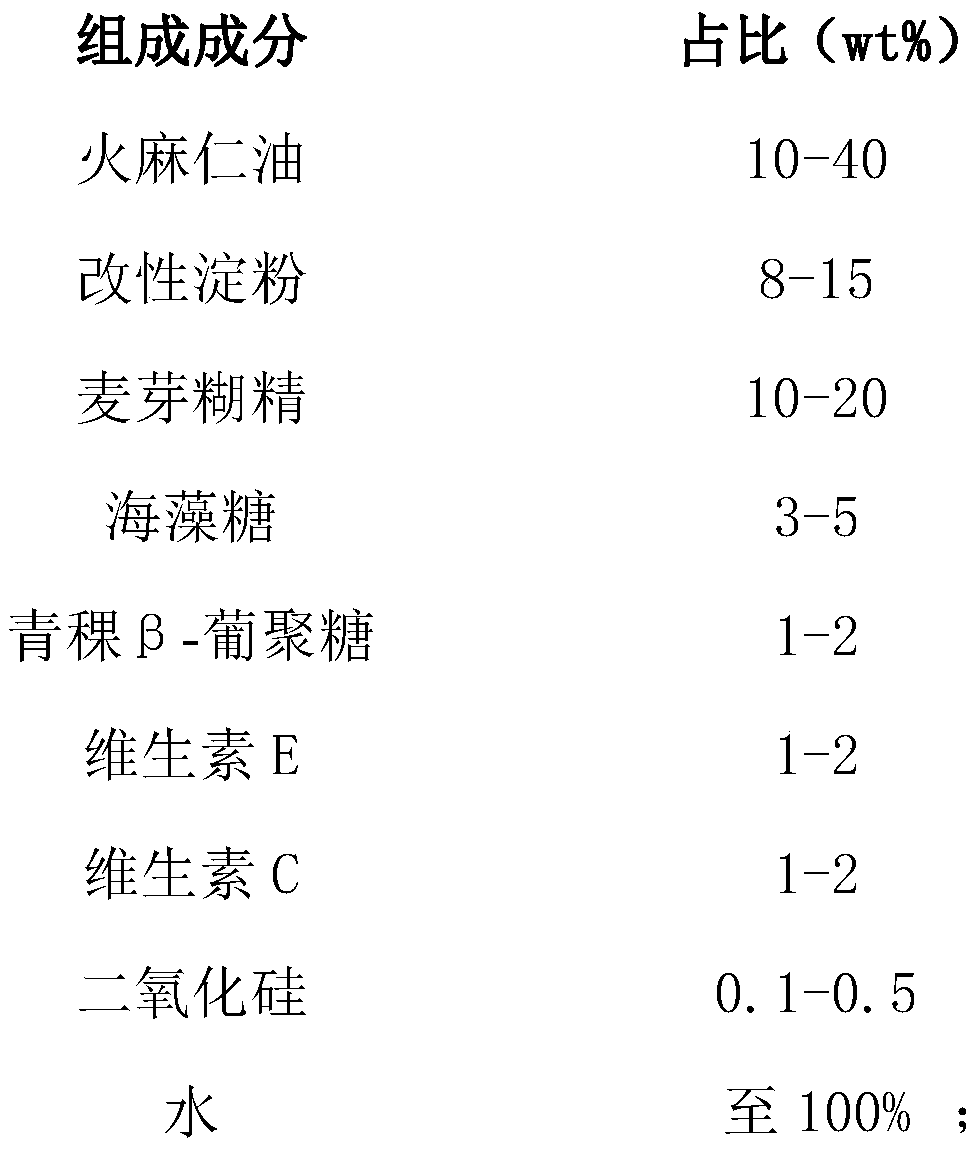

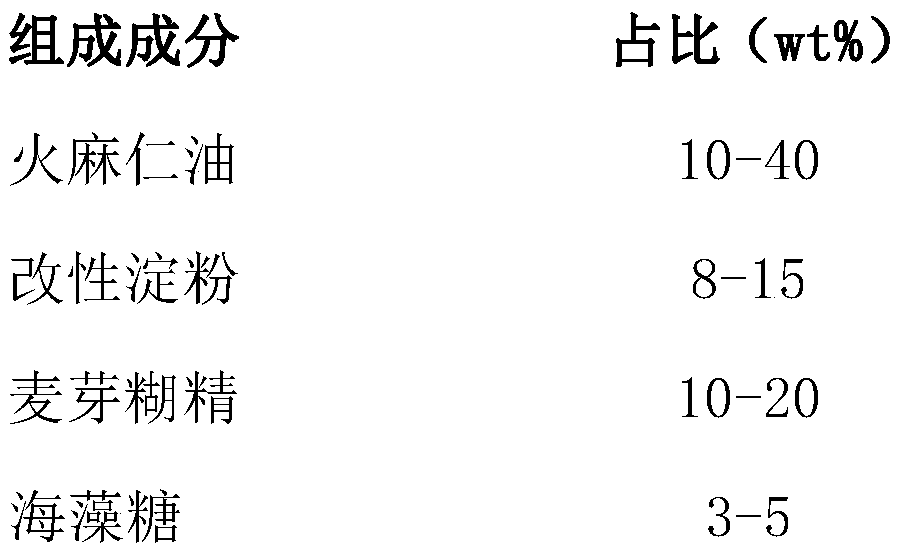

Embodiment 1

[0032] (1) Preheat the water to 37°C, take an appropriate amount to dissolve the modified starch to prepare a modified starch solution, and then dissolve the remaining water to dissolve maltodextrin, trehalose, highland barley β-glucan, vitamin C, and silicon dioxide , and mixed with the modified starch solution evenly. Modified starch is obtained by gelatinization and enzymatic hydrolysis. It will not change the basic chemical structure of starch, but enzymatic hydrolysis will increase the crystallinity of starch, while gelatinization will reduce it; modified starch has strong adsorption capacity, pores Many other features.

[0033] (2) Hemp seed oil is preheated to 37 DEG C, and mixed with vitamin E evenly, the unsaturated fatty acid content in the hemp seed oil is 90.3%. Both vitamins C and E are antioxidants to prevent the two-phase (water phase, oil phase) materials from being oxidized during processing.

[0034] (3) Put the homogeneous solution obtained in step 1 and s...

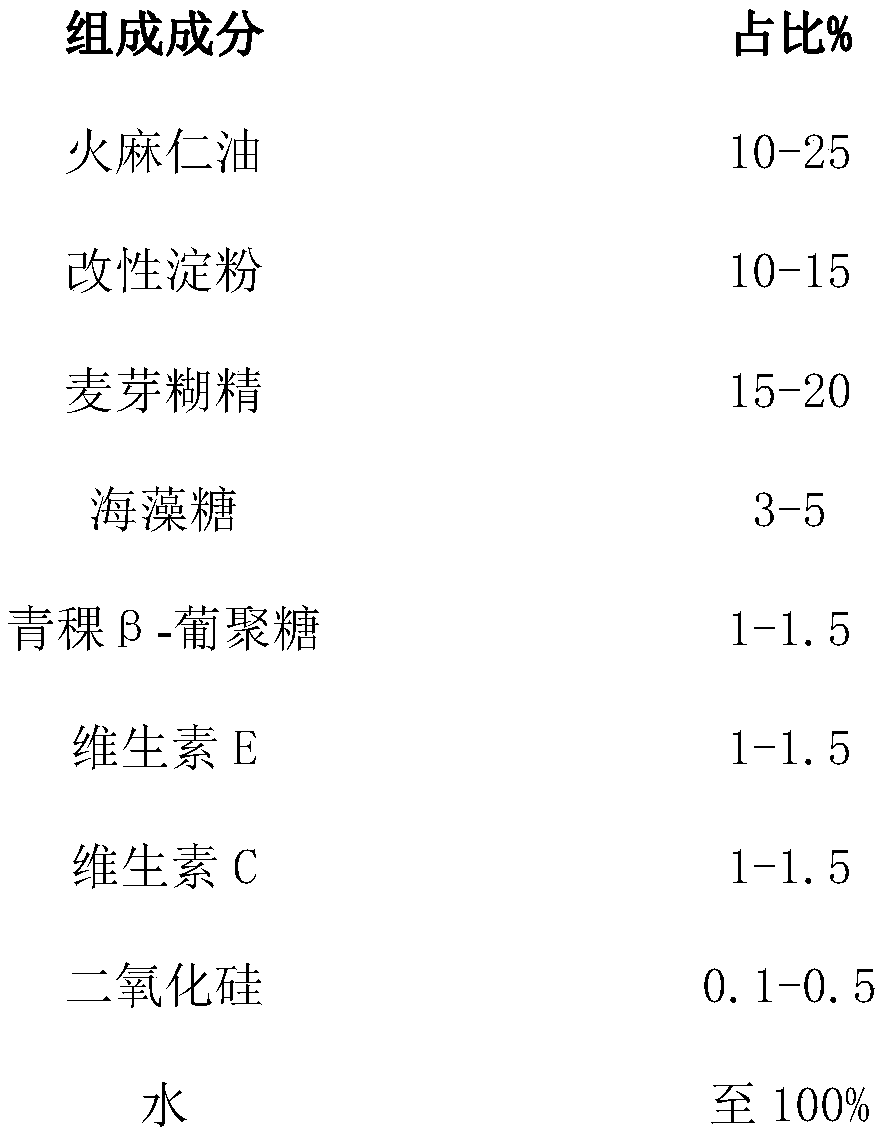

Embodiment 2

[0040] (1) Preheat the water to 38°C, take an appropriate amount to dissolve the modified starch to prepare a modified starch solution, and then dissolve the remaining water to dissolve maltodextrin, trehalose, highland barley β-glucan, vitamin C, and silicon dioxide , and mixed with the modified starch solution evenly.

[0041] (2) Hemp seed oil is preheated to 38 DEG C, and is mixed with vitamin E evenly, and the unsaturated fatty acid content in the hemp seed oil is 91.6%.

[0042] (3) Put the homogeneous solution obtained in step 1 and step 2 into the shearing tank for mixing, and perform high-speed shearing at a shearing speed of 28,000 rpm, shearing 3 times, 90s each time, cooling to 28°C before each shearing .

[0043] (4) After step 3 shearing, high-pressure homogenization is performed twice, with a pressure of 30 MPa, and each time before high-pressure homogenization, it is cooled to 28°C.

[0044] (5) After step 4 is homogenized, carry out spray drying, control the...

Embodiment 3

[0048] (1) Preheat the water to 39°C, take an appropriate amount to dissolve the modified starch to prepare a modified starch solution, and then dissolve the remaining water to dissolve maltodextrin, trehalose, highland barley β-glucan, vitamin C, and silicon dioxide , and mixed with the modified starch solution evenly.

[0049] (2) Hemp seed oil is preheated to 39 DEG C, and is mixed with vitamin E evenly, and the unsaturated fatty acid content in the hemp seed oil is 90.5%.

[0050] (3) Put the homogeneous solution obtained in step 1 and step 2 into the shearing tank for mixing, and perform high-speed shearing at a shearing speed of 28,000 rpm, shearing 3 times, each time for 90s, and cooling to 30°C before each shearing .

[0051] (4) After step 3 shearing, high-pressure homogenization is performed twice, the pressure is 30 MPa, and each time the high-pressure homogenization is cooled to 30°C.

[0052] (5) After step 4 is homogenized, carry out spray drying, control the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com