A kind of preparation method and application of graphene-bismuth tungstate

A technology of bismuth tungstate and graphene, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low price, limited visible light response range, and difficult to take into account Good catalytic effect and other problems, to achieve the effect of increasing active sites, improving catalytic performance, and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

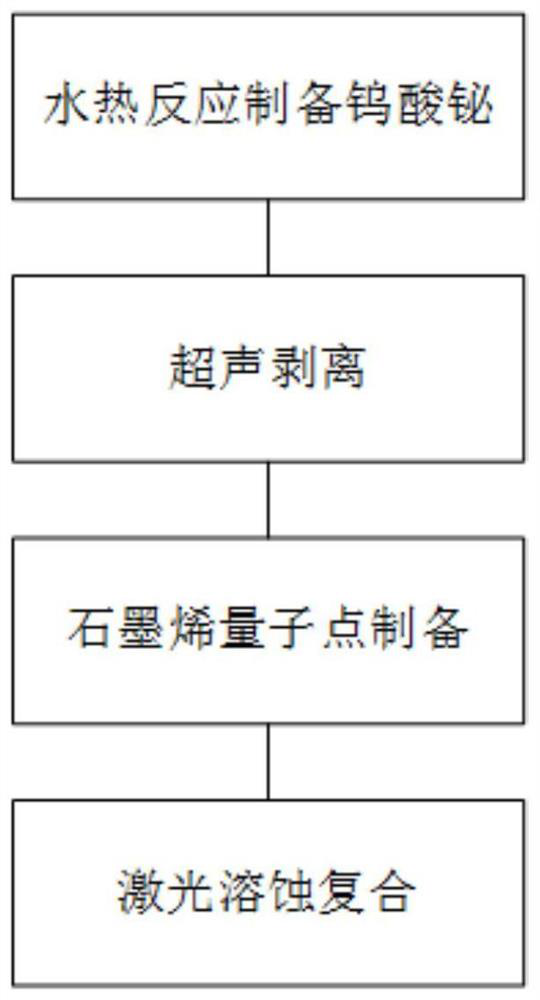

Method used

Image

Examples

Embodiment 1

[0031] Step 1, weigh 1 mmol of sodium tungstate (NA 2 WO 4 · 2h 2 O), 2mmol nitrate (Bi (NO) 3 ) 3 · 5h 2 O) 0.05 GCTAB was mixed in 80 ml of deionized water, at room temperature, stirring at room temperature for 30 min to uniform, transferred to the hydrothermal reaction, wherein the temperature of the hydrothermal reaction was 120 ° C. The temperature of the hydrothermal reaction is 20 h. After the hydrothermal reaction, it was washed and dried, and the tungstate is obtained by washing and dried; wherein the washed method is water and ethanol, respectively, and the drying method is: 70 ° C drying for 10 h.

[0032] Step 2, take a step of 1 step, tungstate 400 mg, soluble in 200 ml deionized water, and ultrasonically peeled off after dissolving to obtain two-dimensional tungsten tungsten nanofilates; wherein the frequency of ultrasonic dispersion is 20 kHz, ultrasonic dispersion time For 2H.

[0033] Step, 10 mg of graphene dissolve in 10 ml of deionized water, and dissolve graph...

Embodiment 2

[0036] Step 1, weigh 1 mmol sodium tungstate (Na2WO 4 · 2h 2 O), 2mmol nitrate (Bi (NO) 3 ) 3 · 5h 2 O) Following 0.05 GCTAB and dissolved in 80 ml of deionized water, stirred at room temperature for 45 min to uniform, transferred to a hydrothermal reaction, wherein the temperature of the hydrothermal reaction is 140 ° C, water The thermal reaction time is 24h. After the hydrothermal reaction, it was washed and dried, and the tungstate tungstate was obtained; where the washed method was washed twice, the drying method was: 80 ° C drying 12h.

[0037] Step 2, take the stepped layer of tungstate 400 mg, dissolved in 200 ml of deionized water, and then dissolved, ultrasonic peeling, to obtain a two-dimensional tungsterate nano-niocne; wherein the frequency of ultrasonic dispersion is 25 kHz, ultrasonic dispersion time. For 1h.

[0038]Step three, 10 mg of graphene dissolve in 10 ml of deionized water, is sufficiently dissolved with graphene by ultrasonic dispersion of 50 kHz; after d...

Embodiment 3

[0041] Step 1, weigh 1 mmol sodium tungstate (Na2WO 4 · 2h 2 O), 2mmol nitrate (Bi (NO) 3 ) 3 · 5h 2 O) Following 0.05 GCTAB and dissolved in 80 ml of deionized water, stirring at room temperature for 50 min to uniform, transferred to a hydrothermal reaction, wherein the temperature of the hydrothermal reaction is 160 ° C, water The thermal reaction time is 18 h. After the hydrothermal reaction, the tungstonate was sequentially washed and dried, and the tungstate of tungstate was obtained; where the washed method was ethanol 3 times, the drying method was: 60 ° C drying 8 h.

[0042] Step 2, take a step of 1 step, tungstate 400 mg, dissolved in 200 ml of deionized water, soon peeling after dissolving, decentralized two-dimensional tungsterate nanococcal; wherein the frequency of ultrasonic dispersion is 22 kHz, ultrasonic dispersion time It is 3h.

[0043] Step, 10 mg of graphene dissolve in 10 ml of deionized water, is sufficiently dissolved in graphene by ultrasonic dispersion o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com